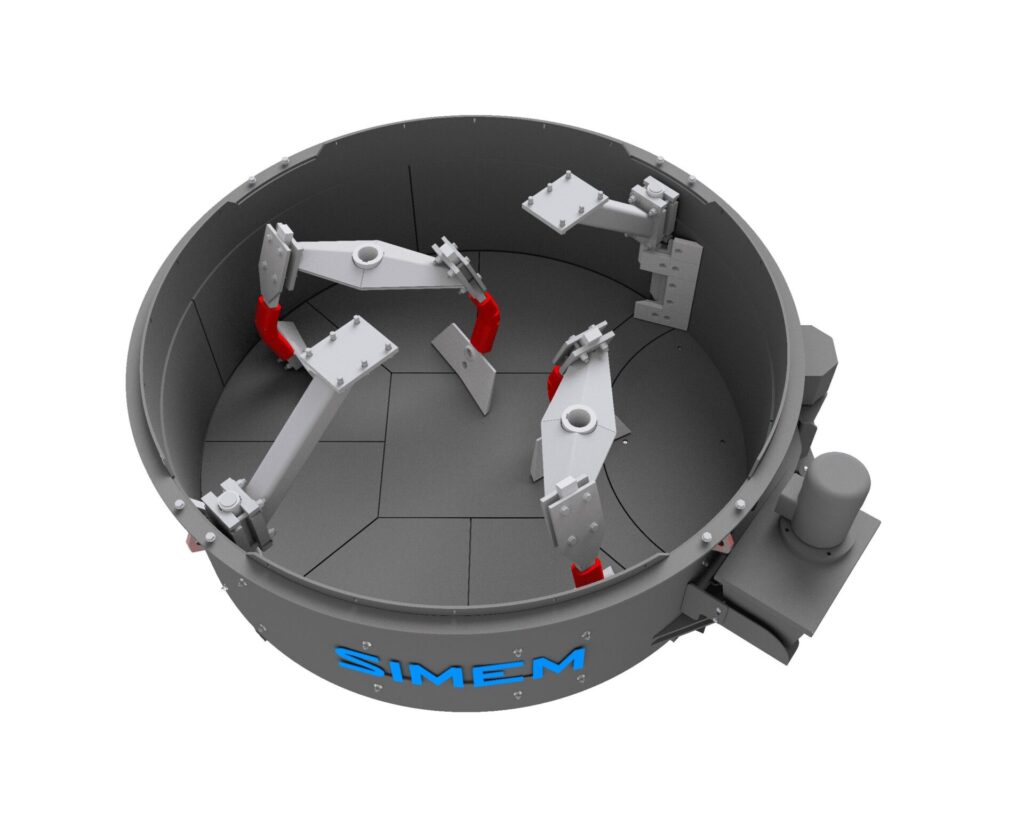

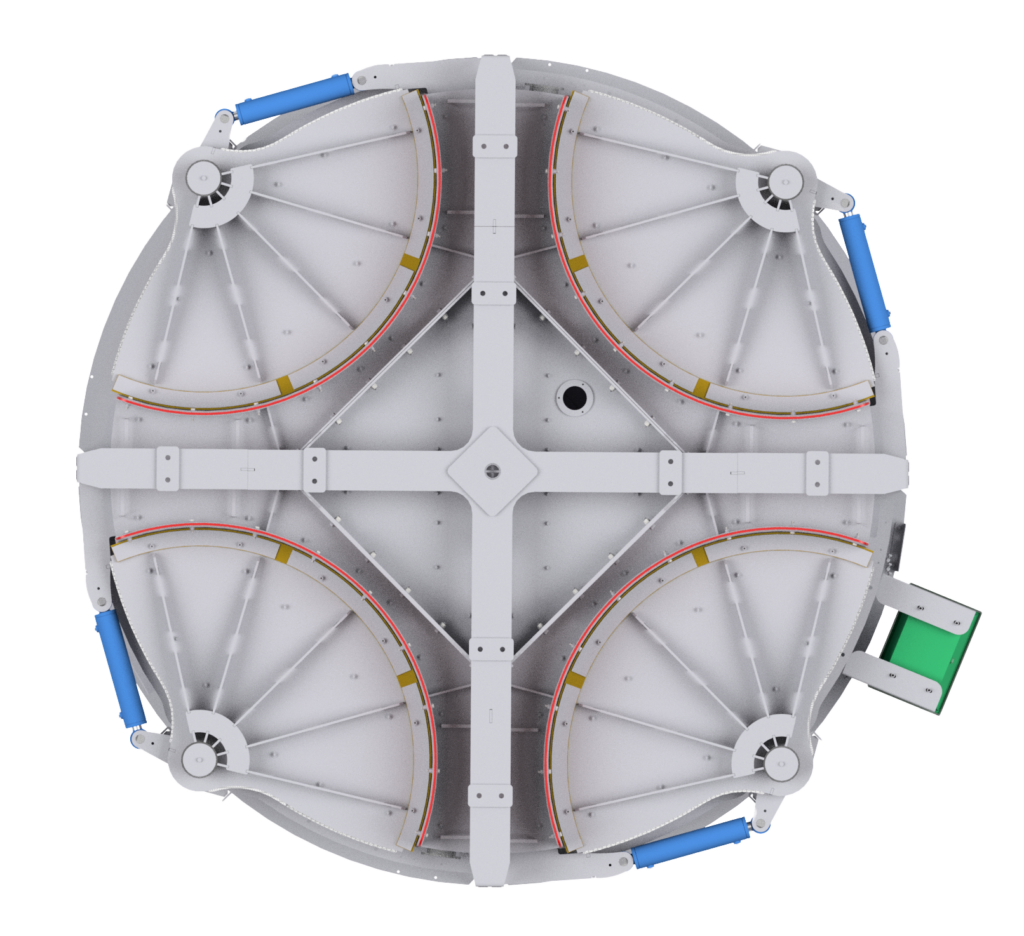

Entry-free paddle

adjustment

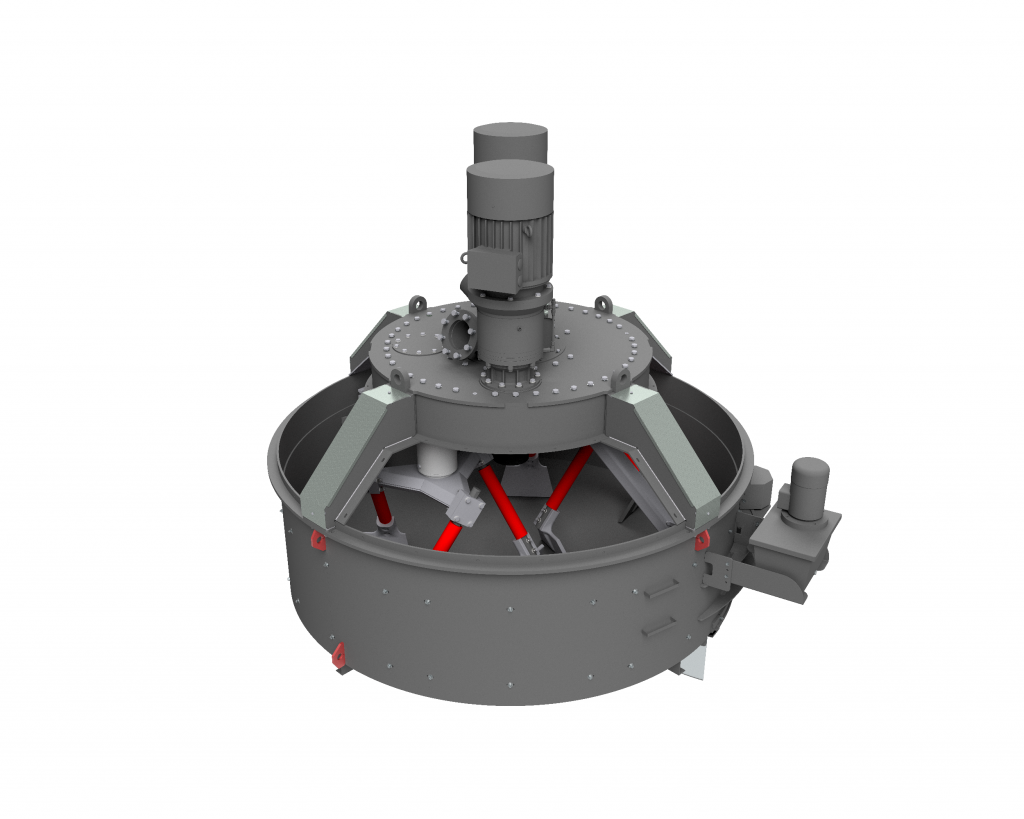

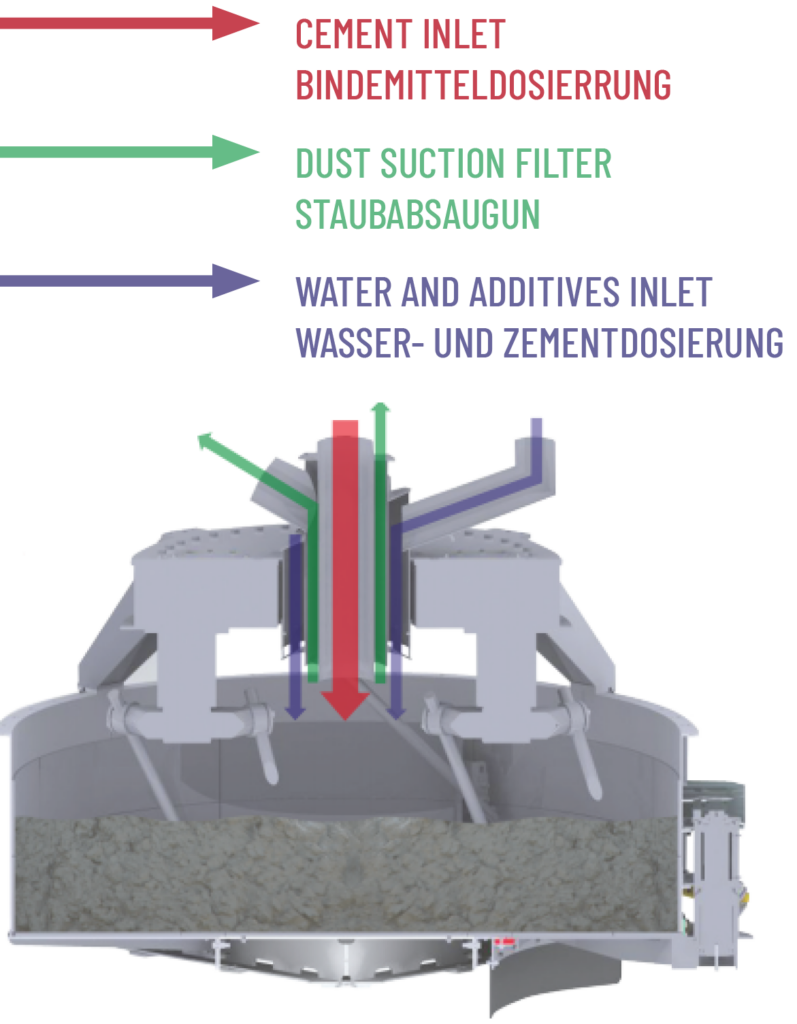

Central inlet

system

Integrated lockout/tagout to

keep everyone safe

Center fill for

powders & liquids

High-performance Planetary Mixer

The mixing process is the most significant and delicate part of the concrete production process and choosing the right mixer for this task is extremely important. With features such as the central inlet of cement and water, as well as the modular design, the XENTRIX planetary mixer has taken planetary mixers to a new level, making them the obvious choice for producing high-quality concrete

Unique Design

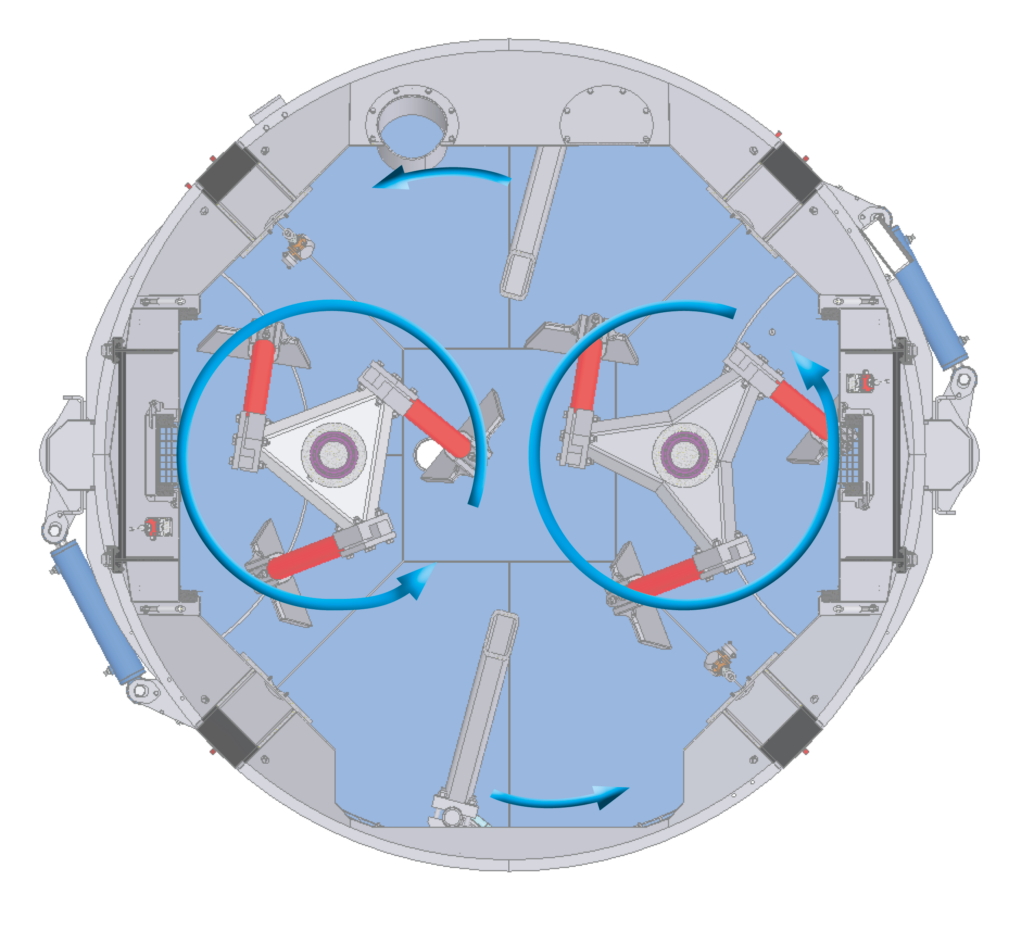

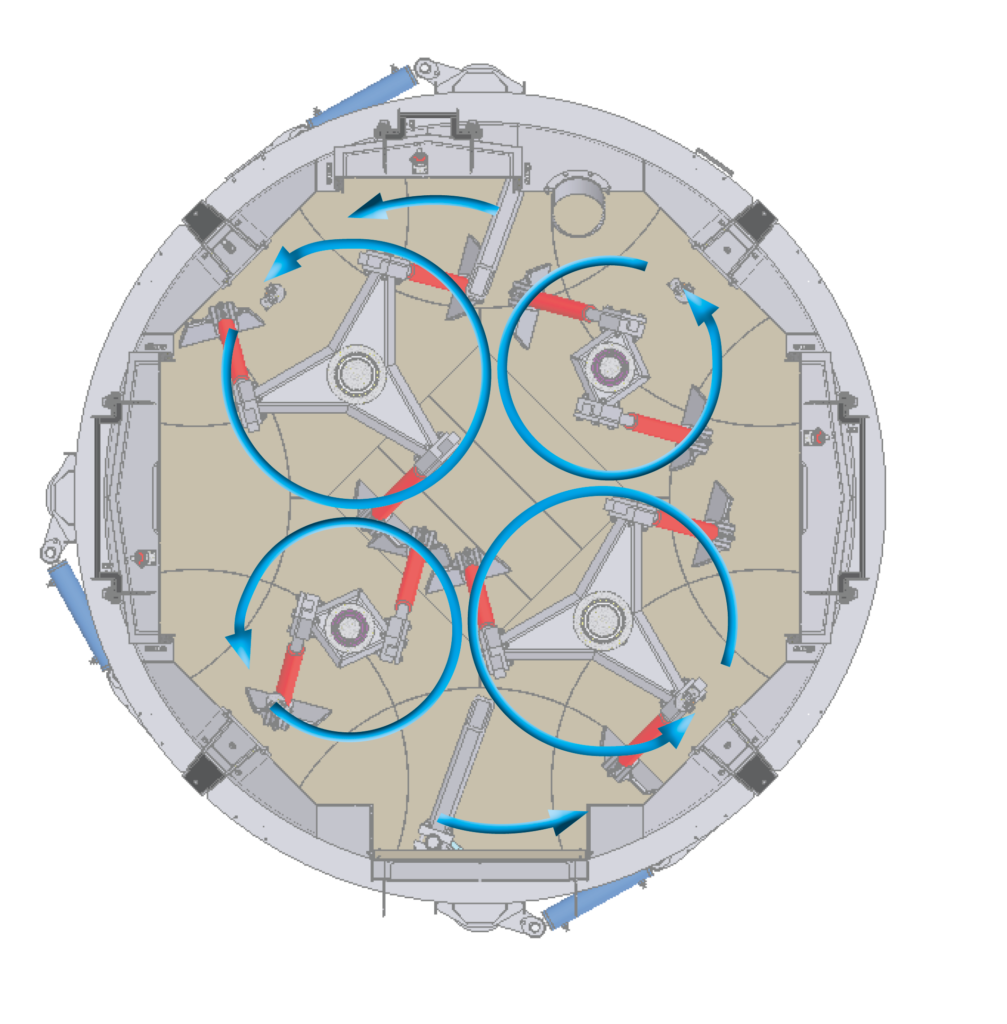

The unique central inlet system allows cement and water to be transported into the mixer from above for homogeneous mixing thanks to the decentralized positioning of the main mixing arms. Mixing is highly efficient thanks to the integrated action of the central satellites (one or two, depending on the model) in planetary rotation for a centrifugal effect, combined with the centripetal effect of the perimeter scraper arms. The water is introduced into the mixer centrally and distributed in a 360° rain pattern. The centralized system includes an aspirator equipped with a fan that thus reduces dust during mixing.

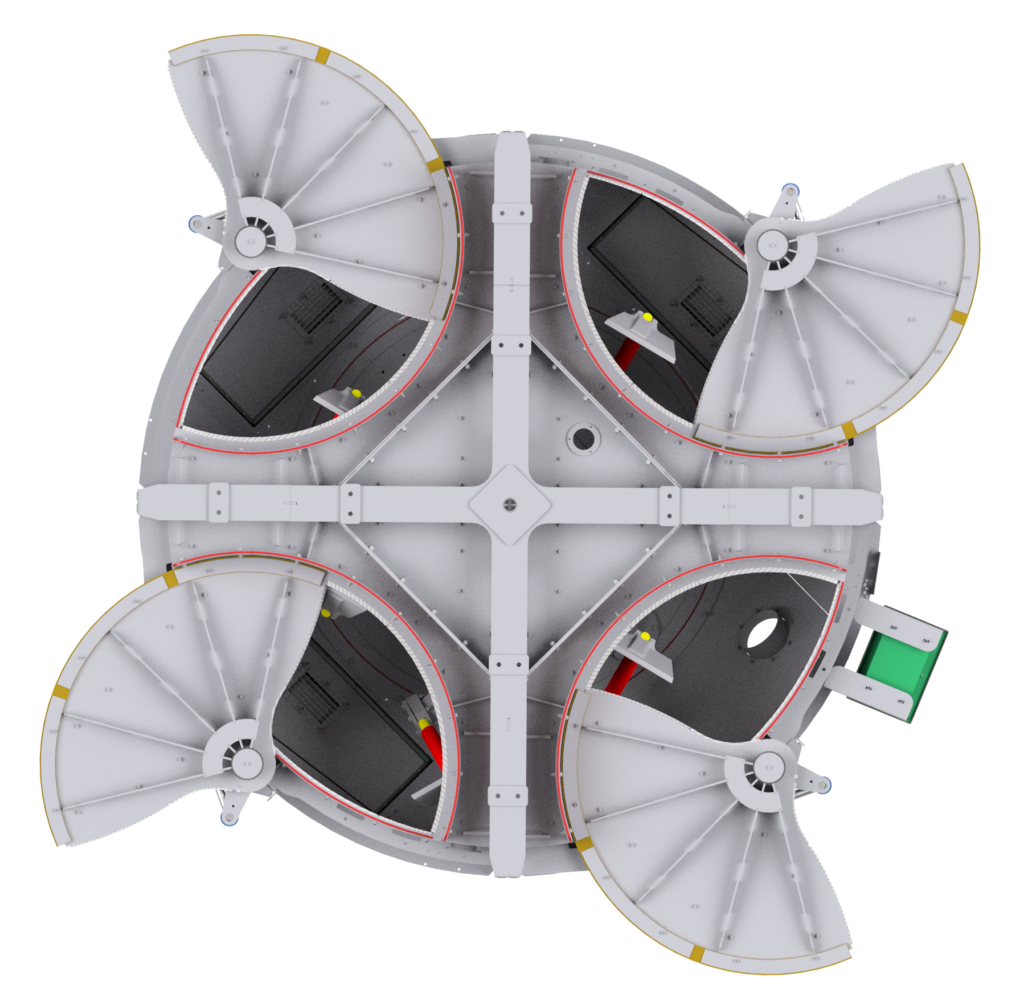

Mixing tank

The mixing tank has been designed to achieve:

EXCELLENT WEAR RESISTANCE

The mixing tank is lined with interchangeable

special steel wear plates or alternative rubber.

FLEXIBLE CONFIGURATION

The tank consists of bolted modules that can be interchanged, making it possible to move or add discharge gates as needed.

EASY ACCESS FOR MAINTENANCE

Cleaning and maintenance are easy to perform through oversized inspection doors. All inspection doors are equipped with the safety devices required by applicable laws and regulations.

Mixing Paddles

The mixing blades are made of cast iron or a cast iron core coated with wear-resistant rubber material. They are designed to optimize material flow and minimize friction and abrasion of the aggregates. All support arms inside the mixing tank are designed in an optimal hydrodynamic shape.

XENTRIX

2000 - 2500 - 3000

XENTRIX

4000 - 4500

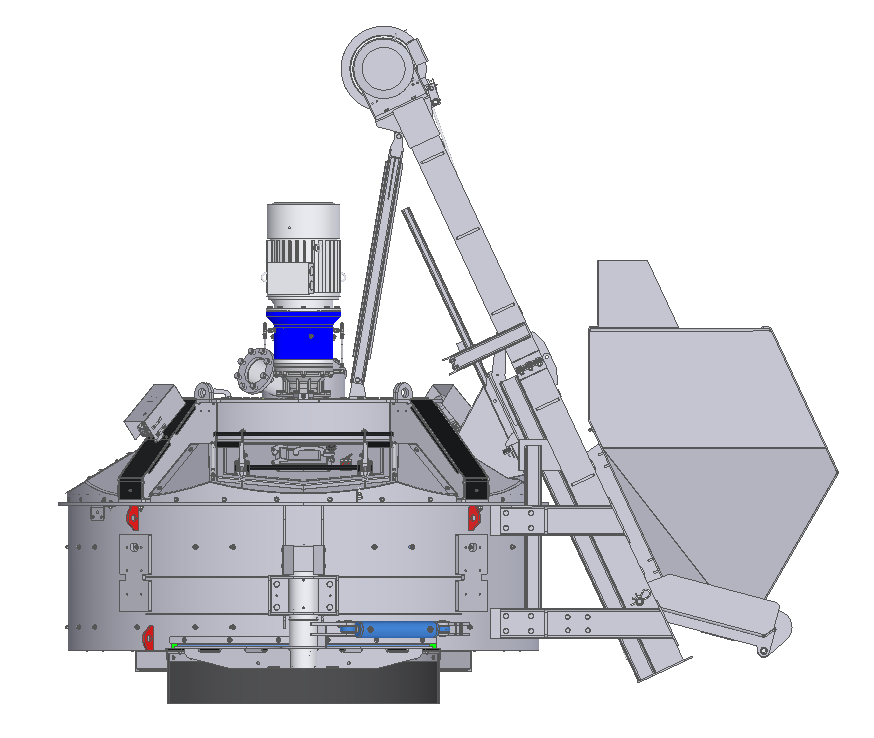

Hydraulic power unit for discharge gate

The mixers discharge gate is controlled by a dedicated hydraulic unit, that grants a correct rotation also when heavy and dry materials are employed.

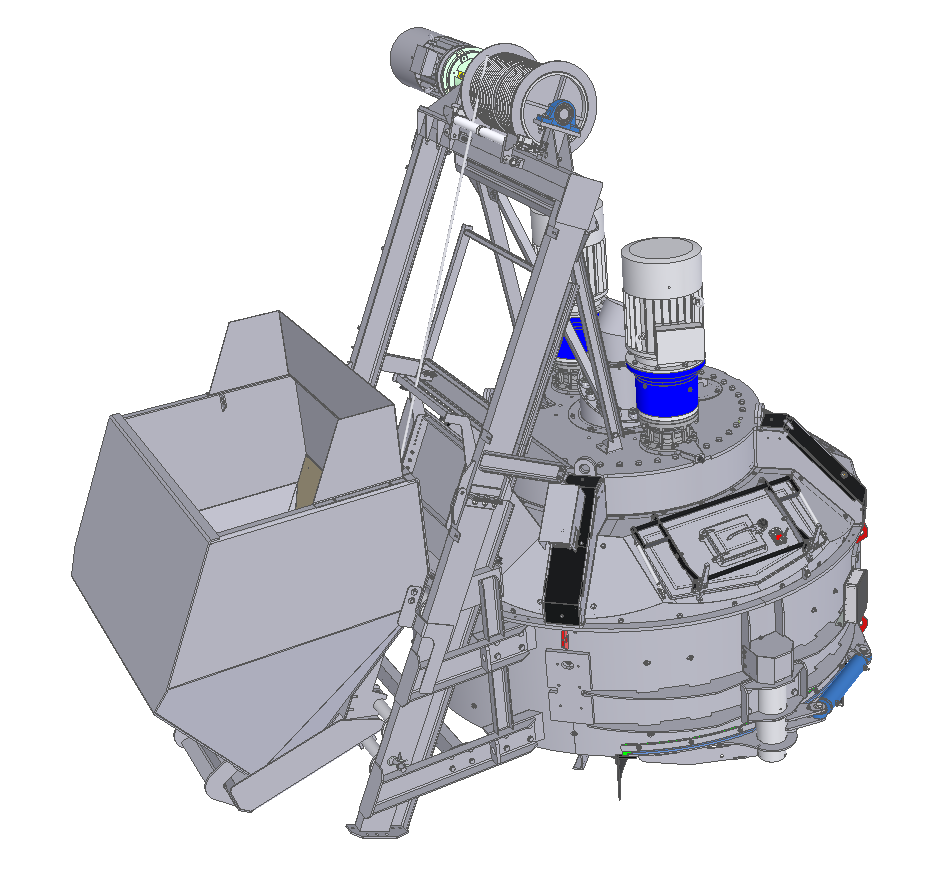

Skip hoist

SIMEM XENTRIX planetary mixers are available with an aggregate loading skip, bottom discharge (no tilting) and the heavy-duty winch high-power self-braking electric motor.