Improved mix result for small

sized aggregate

Reduced

mixing time

Reduced wear on paddle

connection points

Less intensive

mixer cleaning

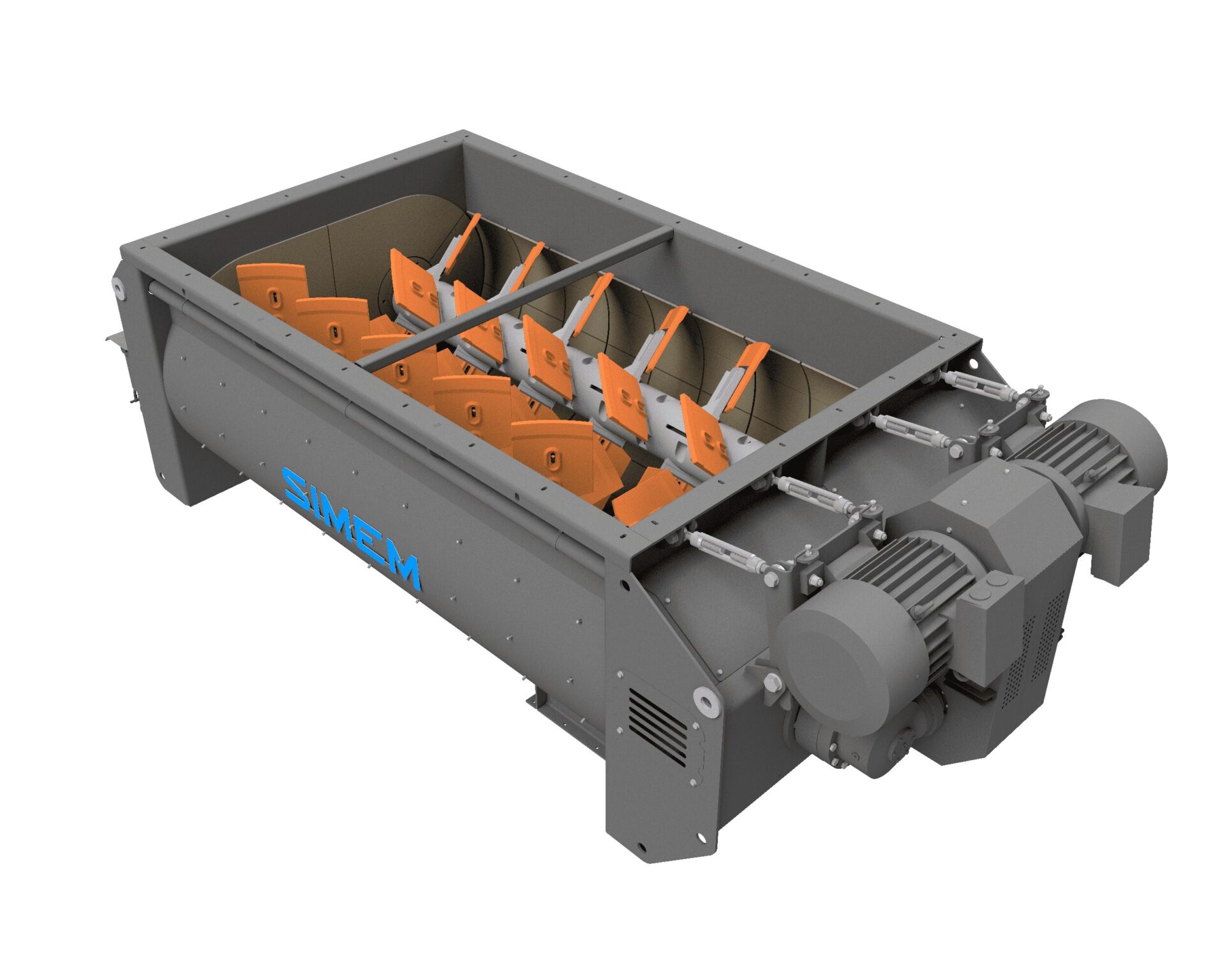

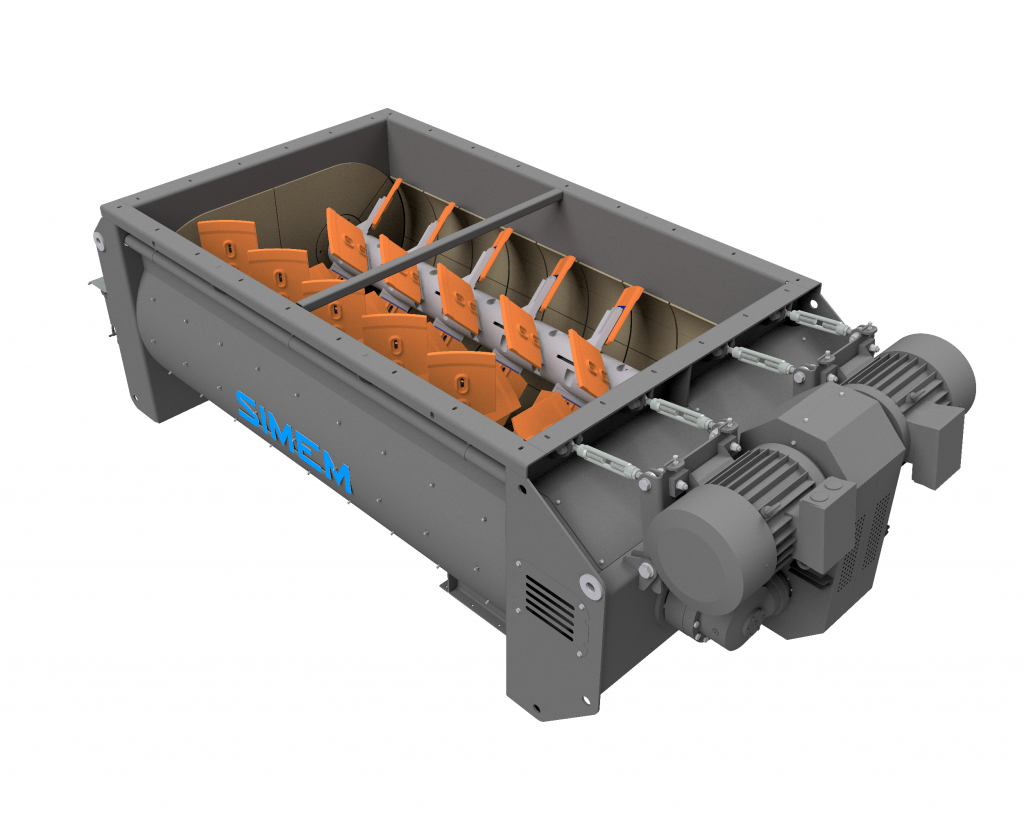

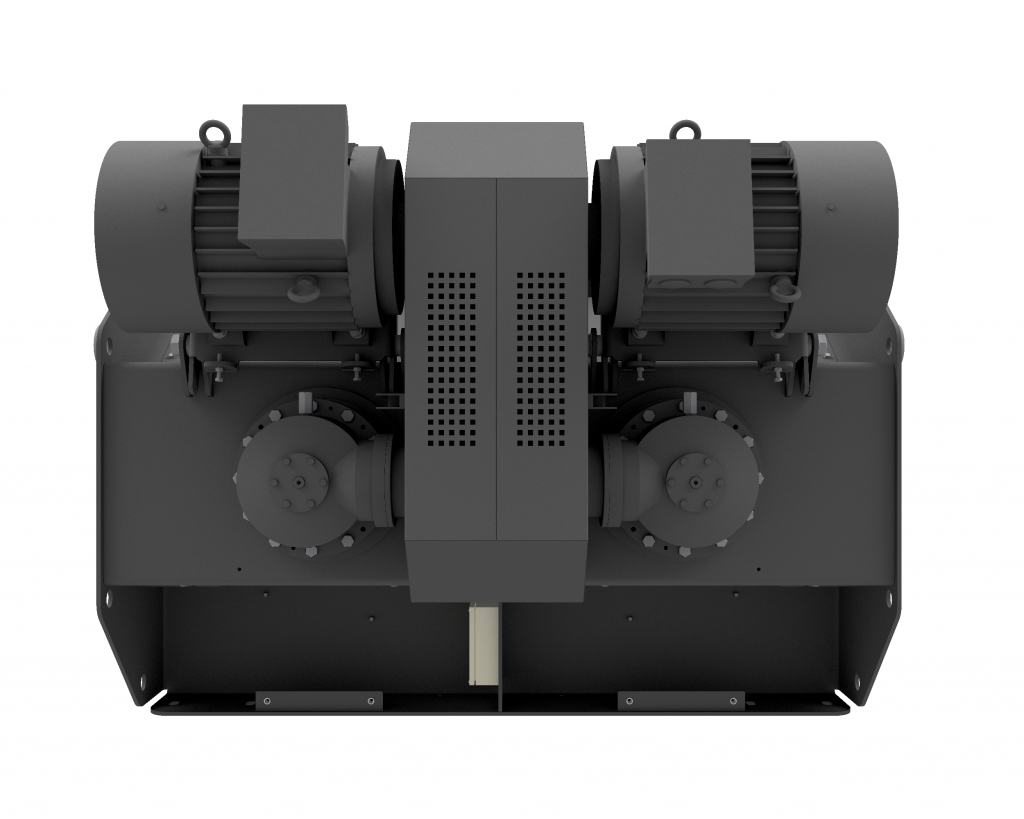

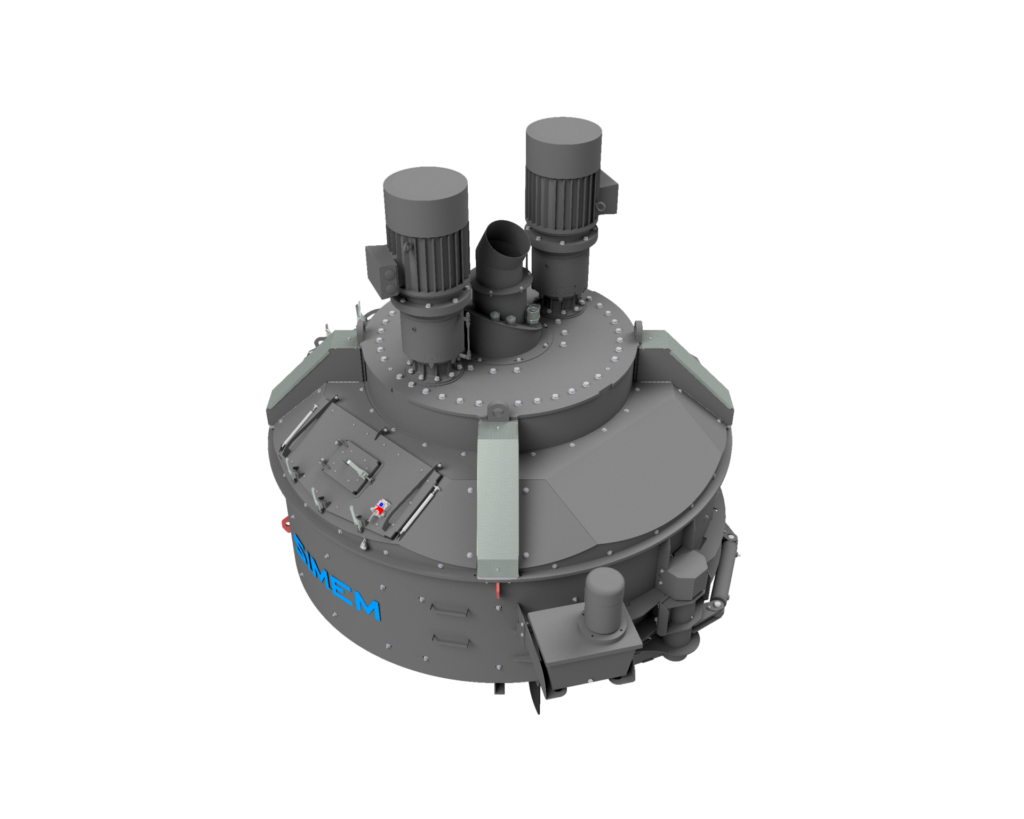

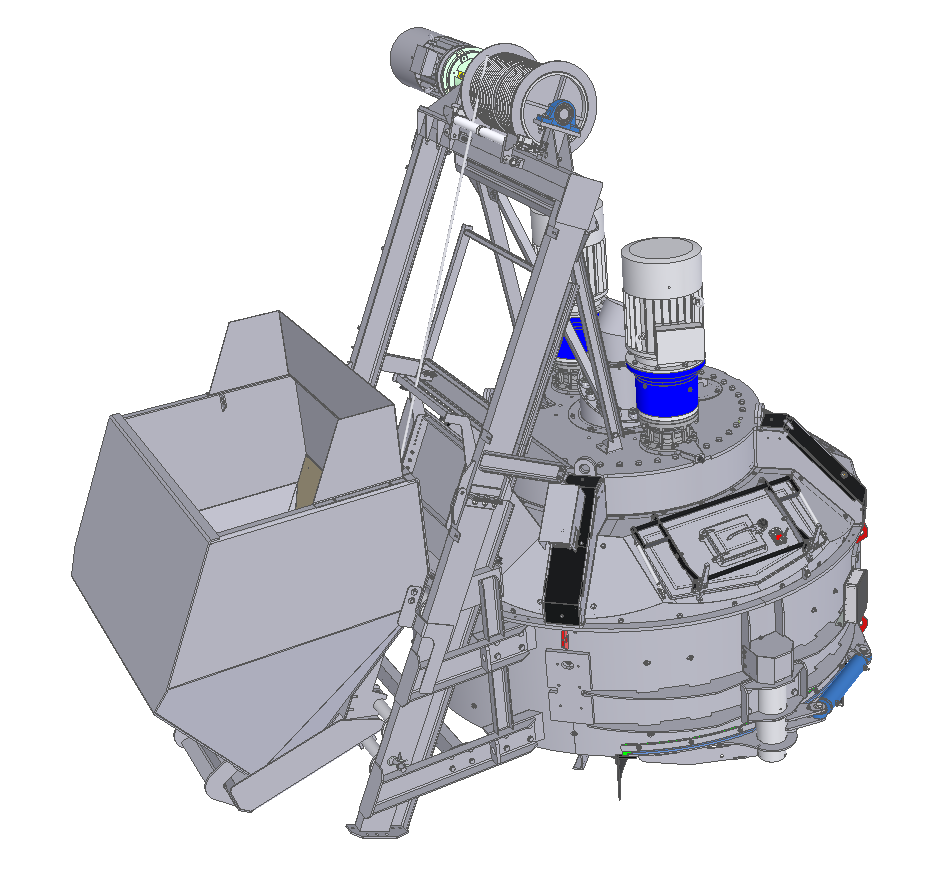

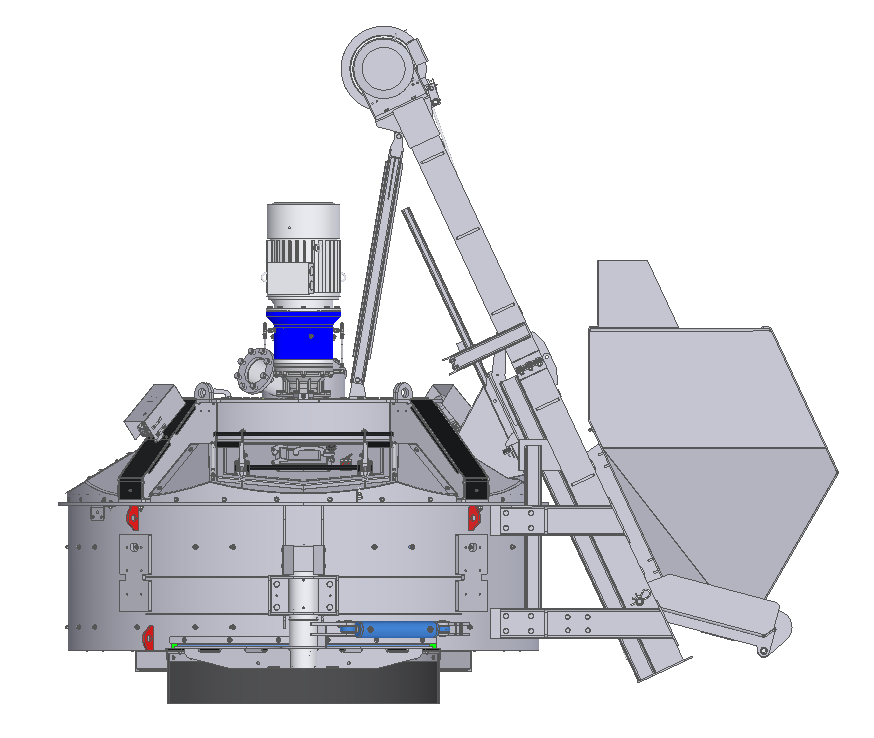

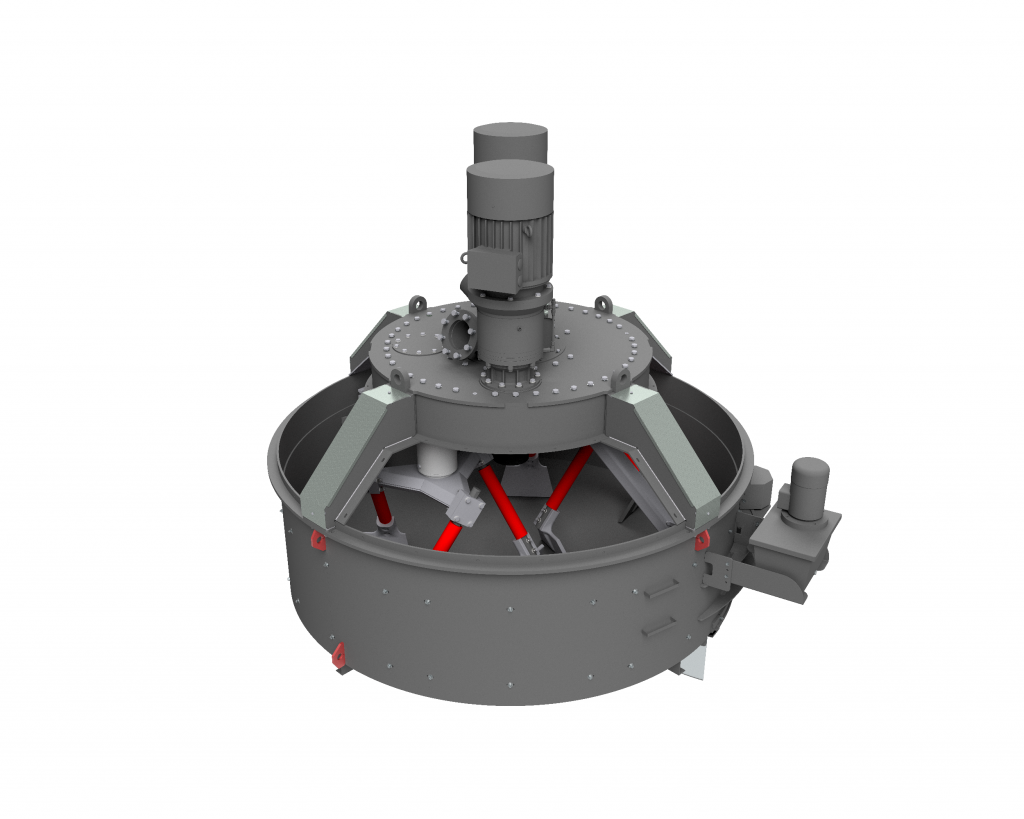

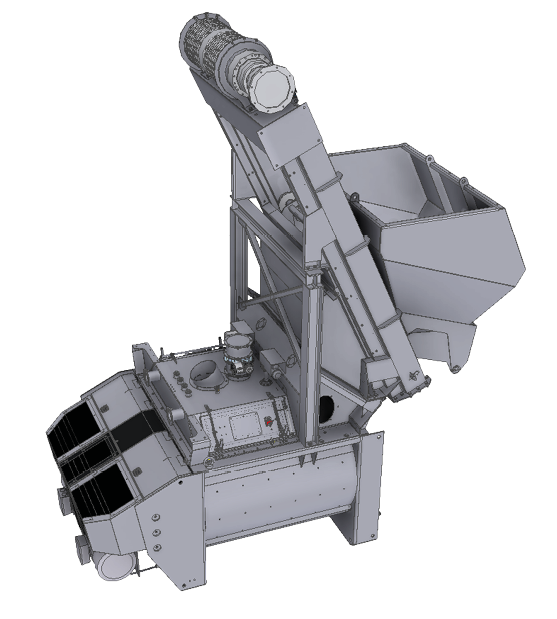

RHYNO Twin shaft Mixer

The Simem RHYNO horizontal twin-shaft mixer represents excellence in the field of mixing thanks to a robust design, intuitive paddle adjustment and mixing action with the innovative DYNA-FLOW technology. This combination of engineering features allows us to realize several advantages, including the high quality of the concrete produced and the reduced maintenance cost of the mixer. RHYNO twin-shaft mixers have a compact concrete production capacity ranging from 1 to 4.5 m³. They are the ideal solution for a range of applications, including compact concrete, SCC, and RCC.

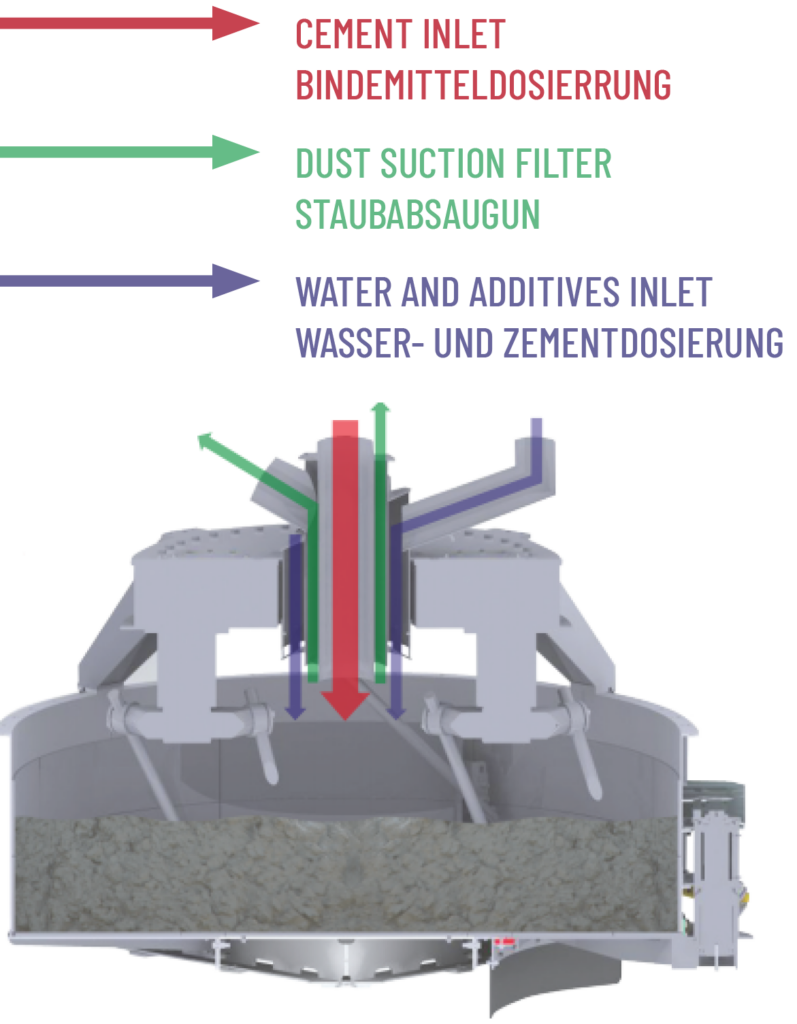

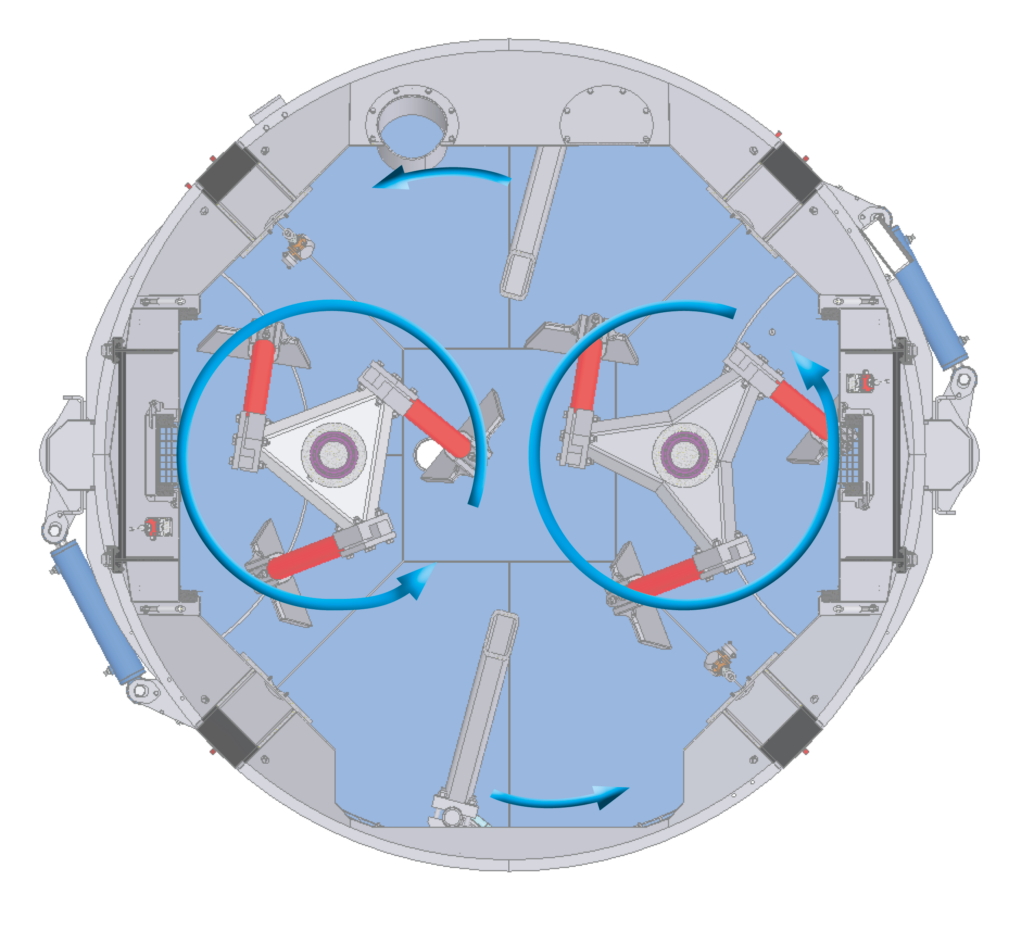

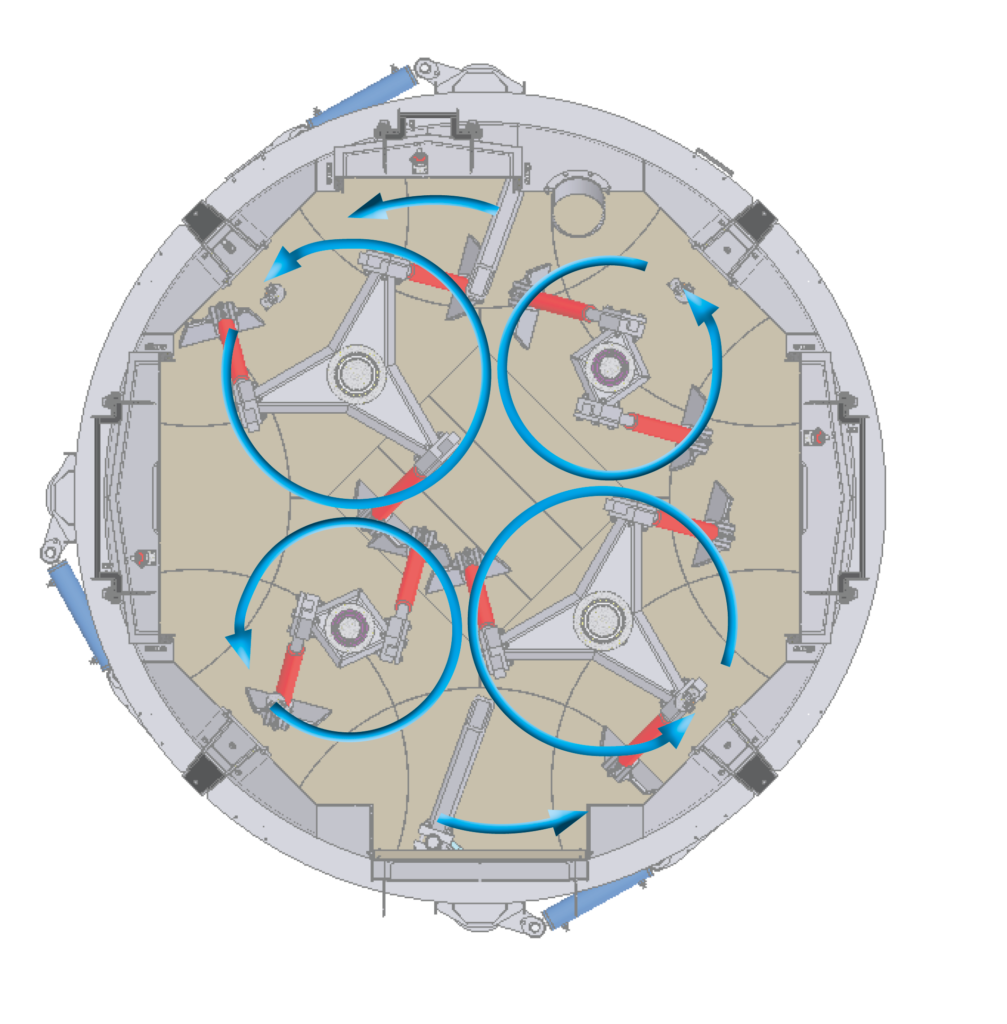

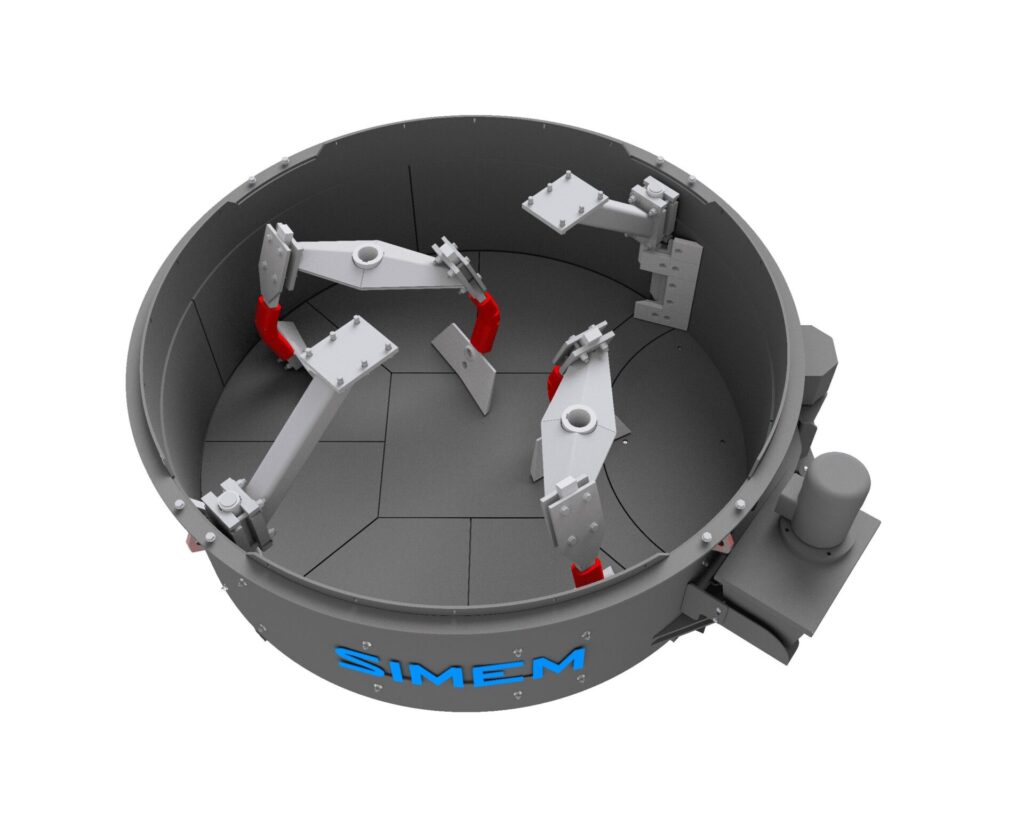

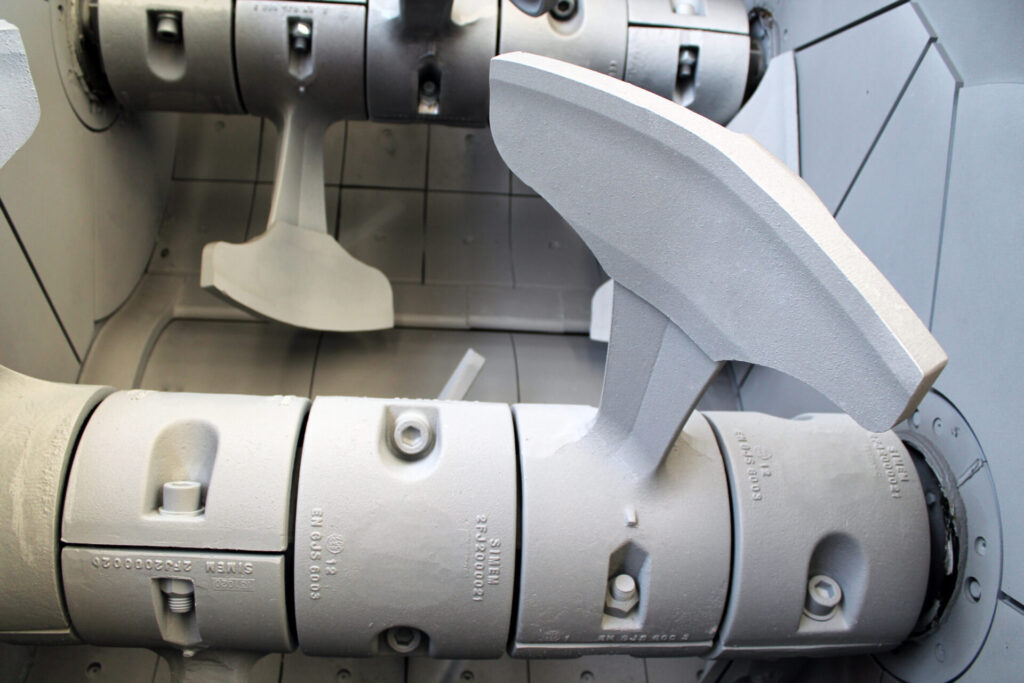

Dyna Flow Mixing System

A cutting-edge fluid dynamic simulation was used to support the design of

the paddle profiles and the connection points of the arms.

Developed in collaboration with the engineering innovation centre at

Padua University, the mixing action has been optimized to provide

additional mixing benefits to concrete producers, including:

• Improved mixing result for small aggregates

• Reduced mixing time and better energy performance

• Reduced wear on the blade connection points

• Less intensive mixer cleaning

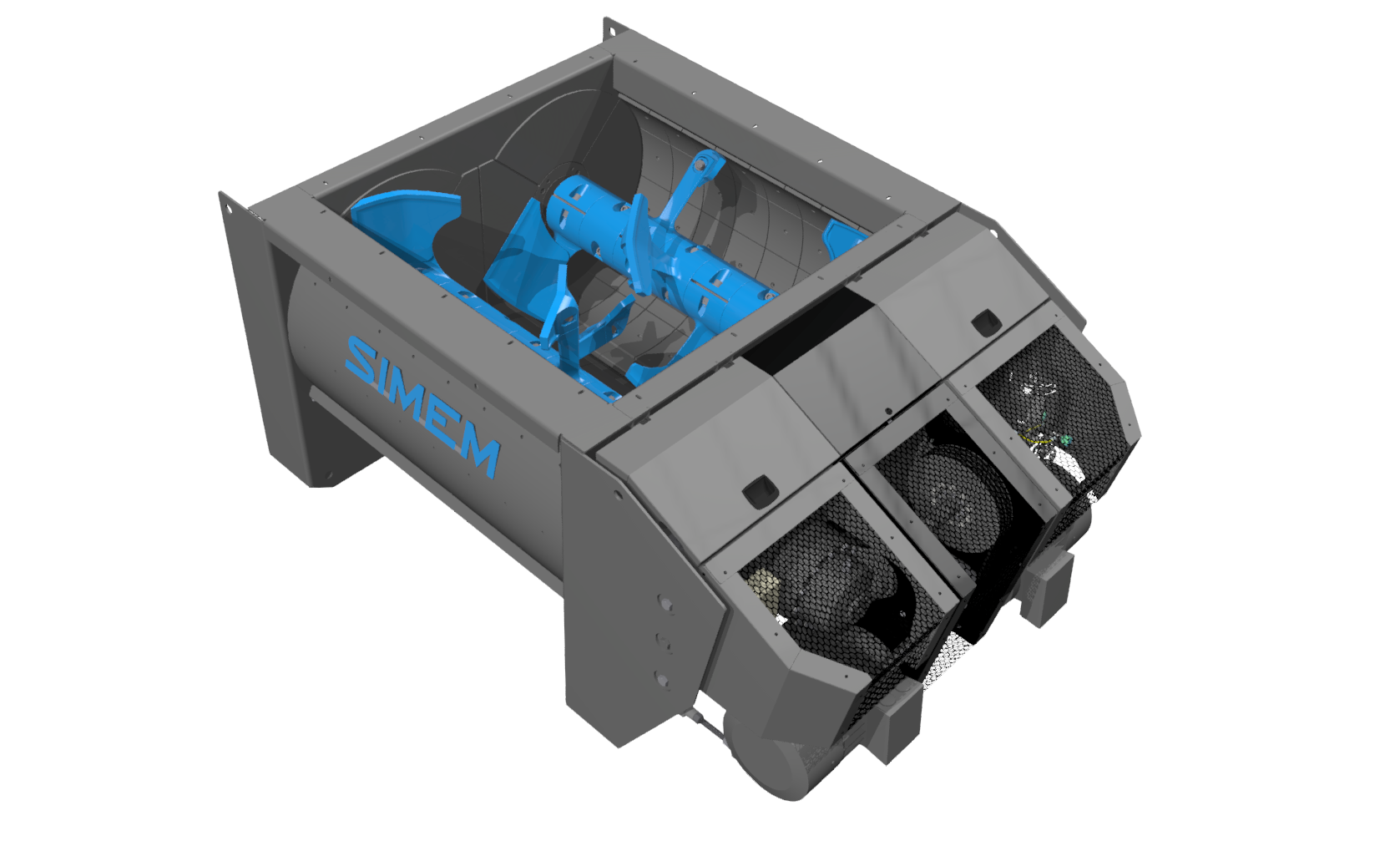

Aggregate Skip Hoist

SIMEM RHYNO twin shaft mixers are available with an aggregate loading skip, bottom discharge (no tilting) and the heavy-duty winch high-power self-braking electric motor

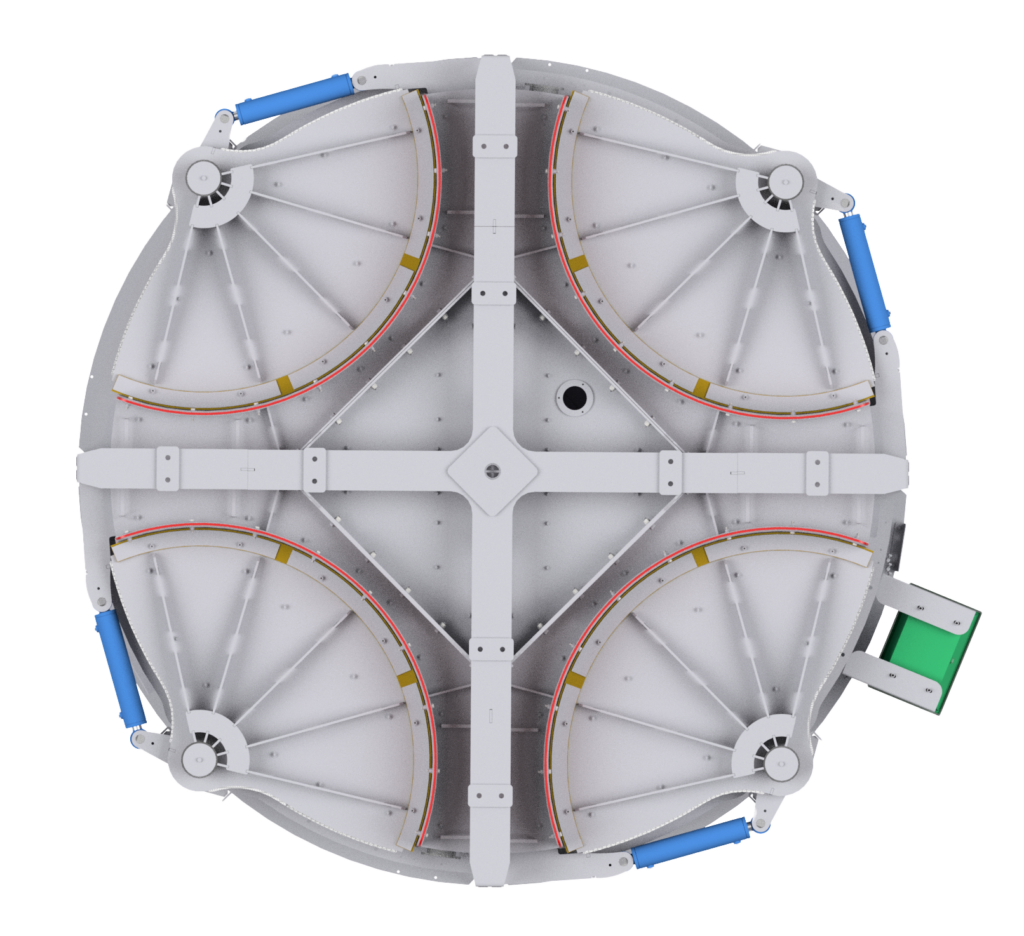

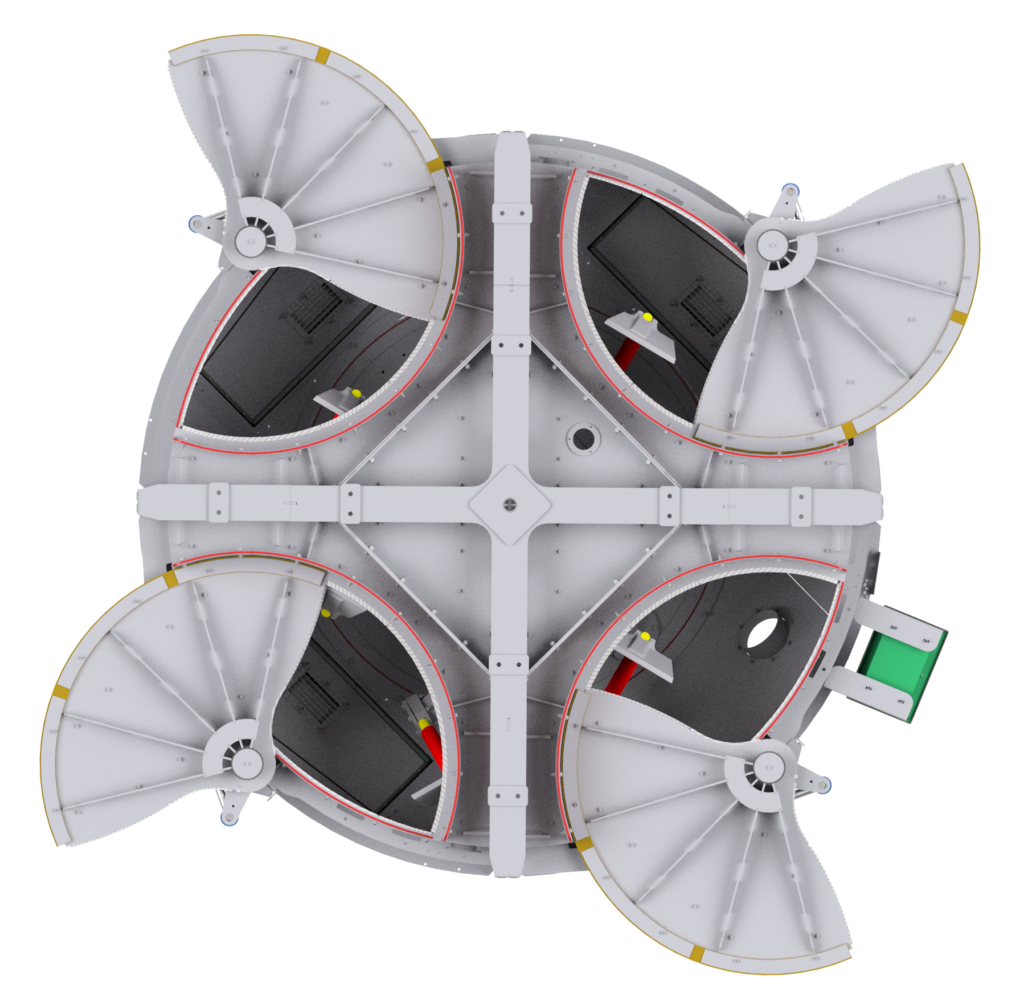

Easy Maintenance

The mixer is the essential element of the system, and its maintenance is therefore fundamental

•An inspection door allows you to check the internal condition of the mixer.

• Arms and paddles are individually bolted, facilitating the easy replacement of spare parts.

• For maintenance of the most sensitive parts (joints, seals, reducers, etc.), the hood can be easily unhooked and partially opened following a tilting movement.

• A manual hydraulic pump allows the discharge door to be opened in case of emergency. The discharge door has limit switches that indicate partial or full opening and closing

High resistance Design

RHYNO twin shaft mixers are lined with stud-mounted high wear resistance liners. RHYNO paddles and arms are bolted to the twin horizontal shafts. The bolt on arm design allows for a various paddle positions to accommodate a variety of mix designs and ease of paddle adjustment.

This method and engineering technology also provides an optimized mixing result.

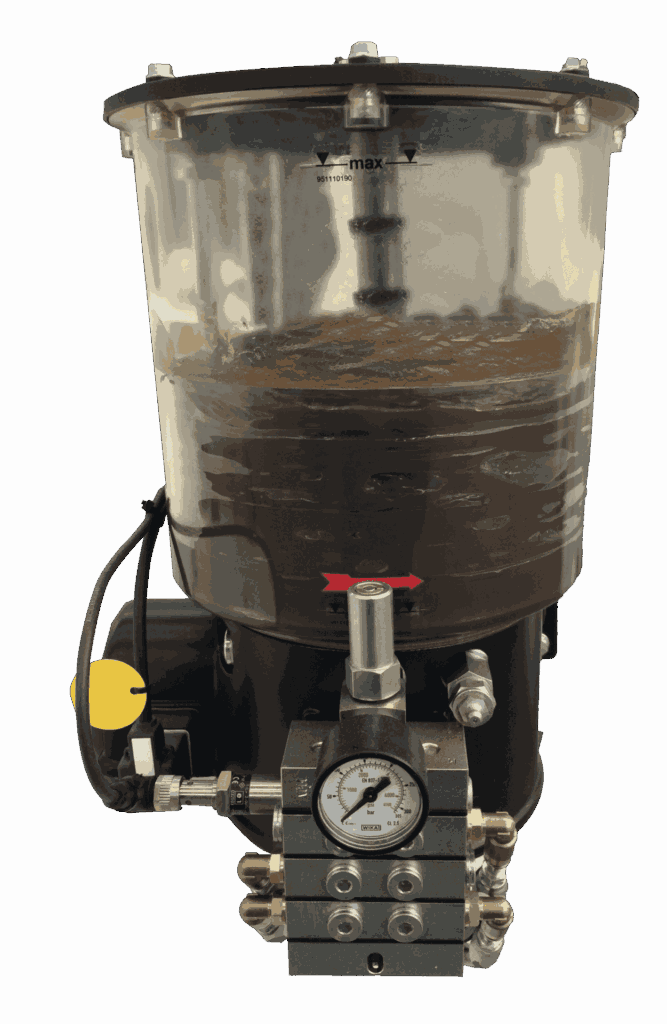

Automatic Greasing System

All Simem mixers are equipped with engineered labyrinth mixer shaft seals. An electrically driven, sensor-monitored grease pump constantly lubricates the seals to safeguard mixer operation and reduce maintenance activities.