Transportable with standard trucks or containers

Production range

from 70 to 180 m3/h

Aggregate storage from 40 to 260 m3

Aggregate storage capacity

from 40 to 260 m3

Highly resistant anti-wear liners all over the materials flow areas

Reliability - EAGLE

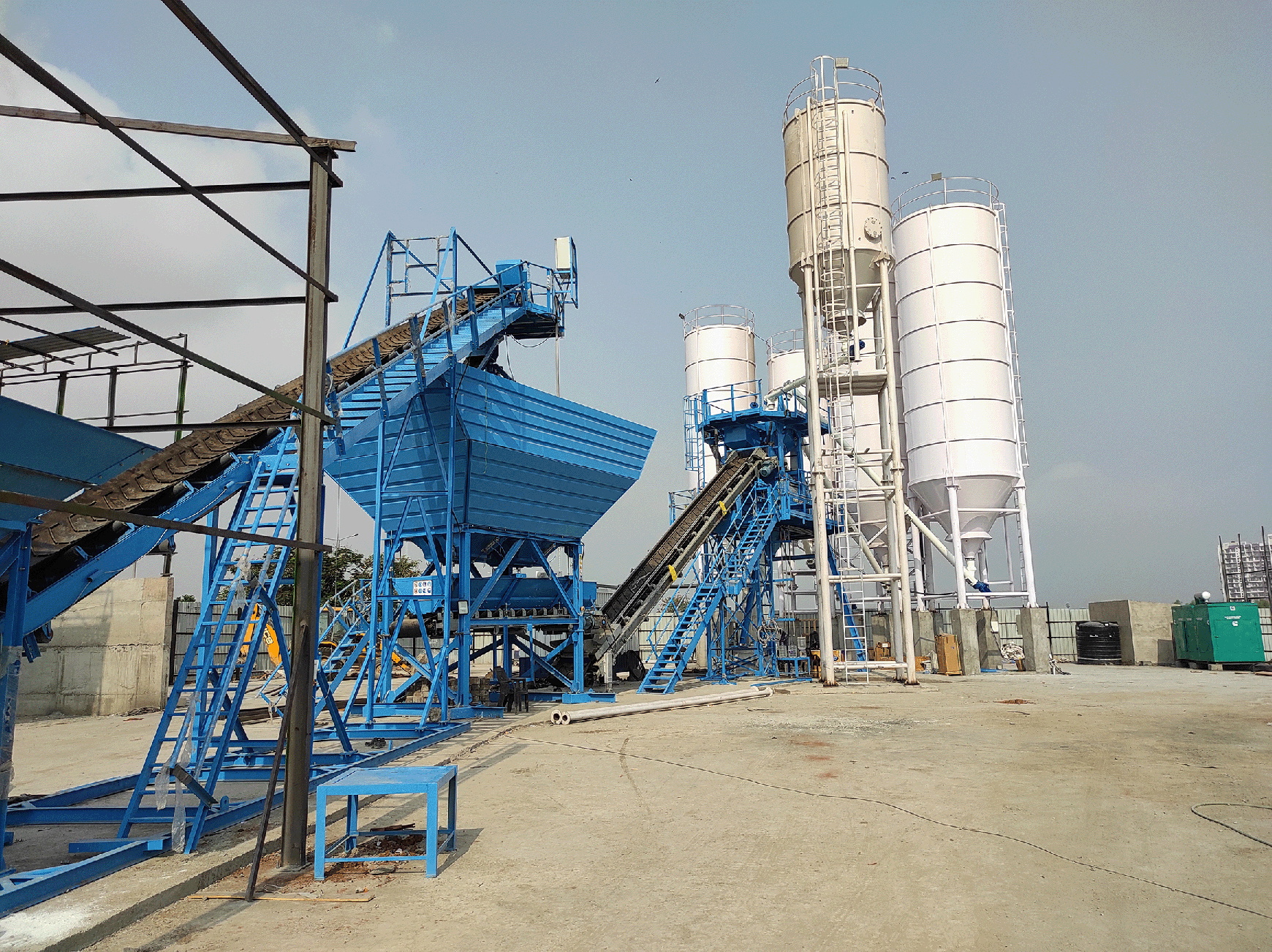

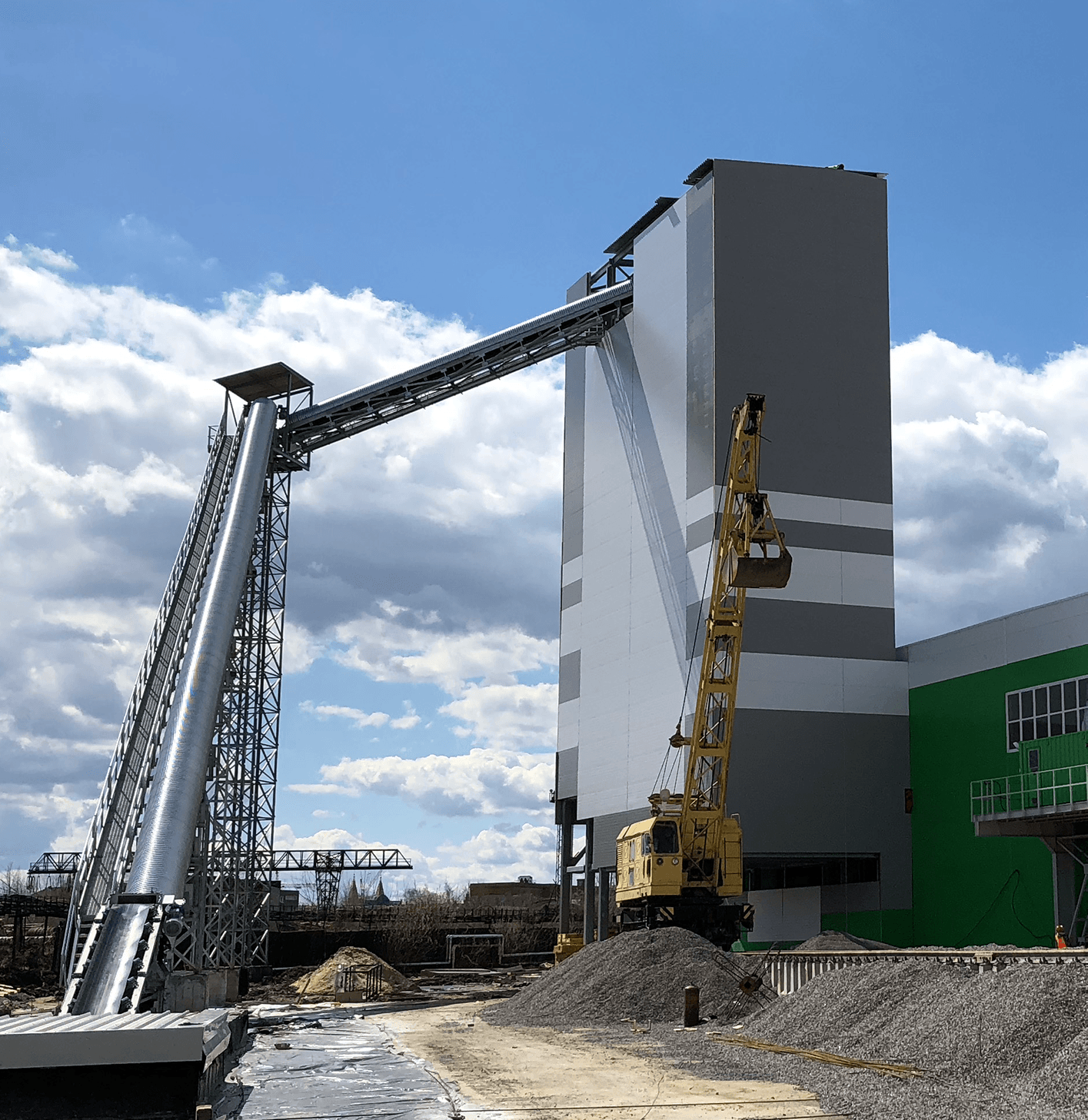

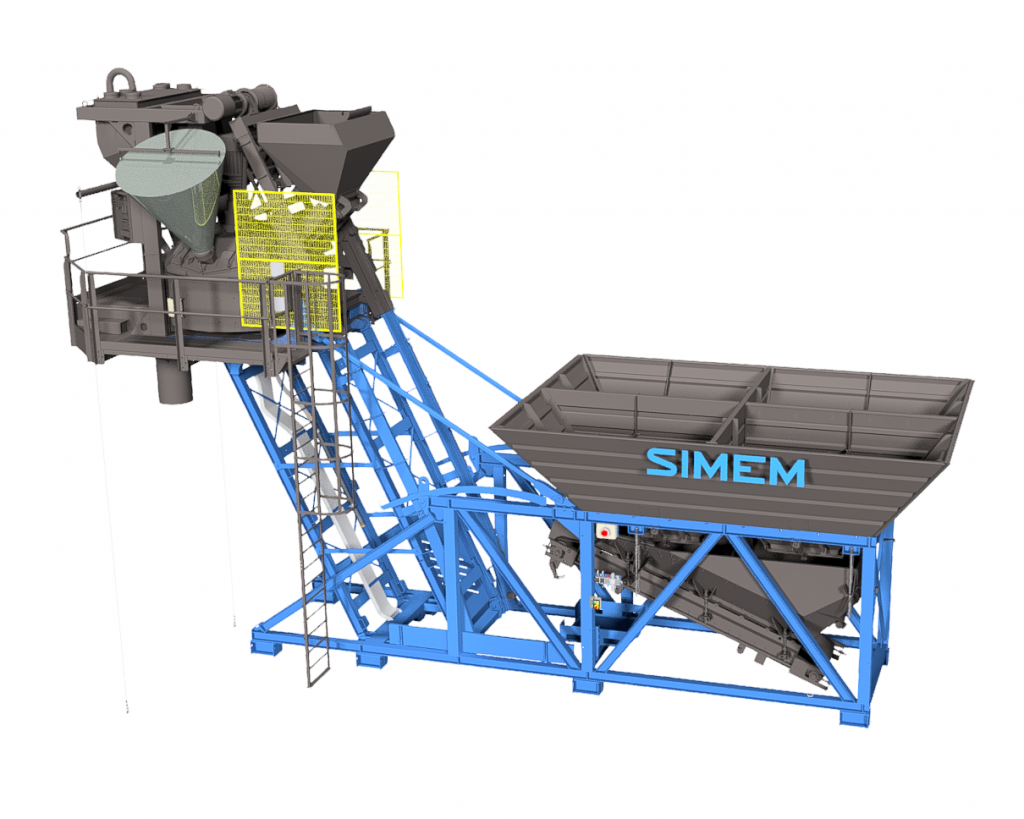

The EAGLE ready-mix concrete plant is known for its reliability and excellence. A robust structure and high-quality components make EAGLE a versatile facility. Easy to transport and even easier to assemble, the EAGLE concrete production plant arrives on site already pre-assembled and pre-wired to minimize operations. The Eagle plant range and the available options make it ideal for large volumes of concrete such as in the case of civil works.

Easy Transport - Mobile unit

All EAGLE plants are pre-wired and pre-assembled, and they can be moved from site to site with standard trucks or stored in containers.

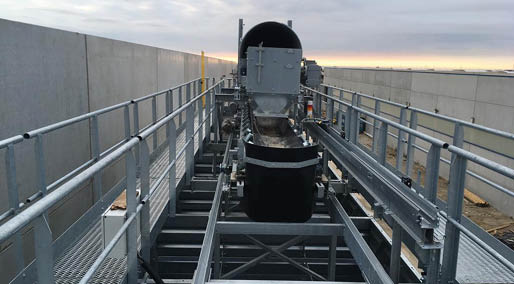

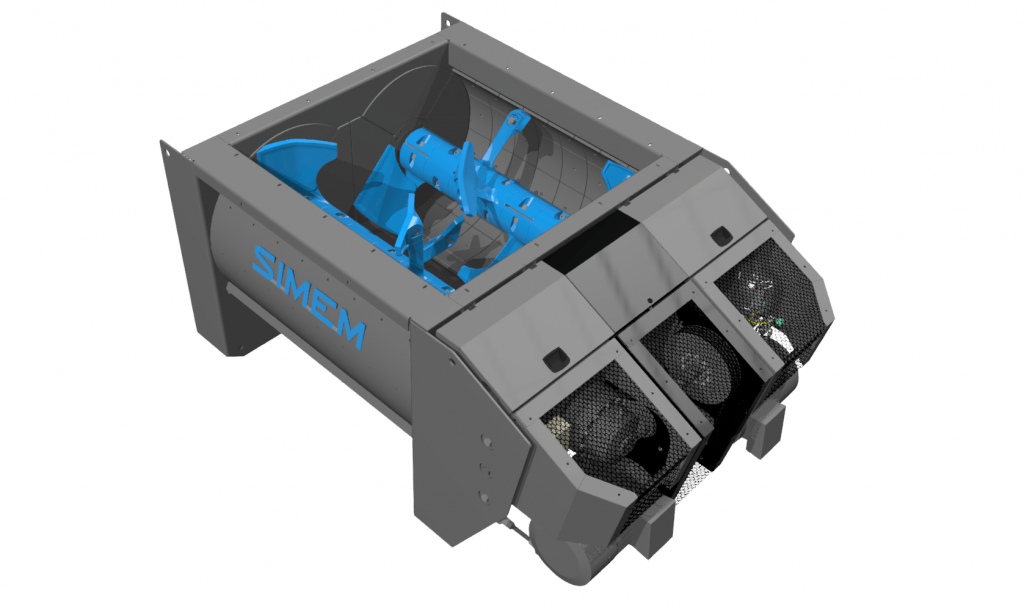

Twin Shaft Mixer - RHYNO

The RHYNO and MSO series of twin shaft mixers offer a wide range of output capacities from 1 to 4.5 m³ with the ability to produce anything from conventional concrete to SCC and RCC with oversized aggregate. SIMEM mixer are known for their reliability, unquestioned durability, and output of high-volume concrete production. SIMEM twin shaft mixers boast a strong design, easy maintenance, and high-quality components This combination of engineered features provides the lowest possible maintenance cost per cubic meter of concrete produced.

Nexus

NEXUS aggregates modular system is a bolt-together structure that can be modified at any time regarding the number of aggregates and storage capacity. Eagle models 2500, 4000 , 5000 and 7000 are also available in MASTER version with aggregates bins sized with compartments 3,8 mts wide for an easy loading by dumper or HD wheel loader.

Concrete Pillars

Steel Legs

Steel Mobile Foundation

Plant Overview - Modularity

The aggregate module is made with a modular concept and can therefore be made expandable by adding additional modules as a priority to expand the number of hoppers available and therefore the types of aggregates.

Regarding the storage capacity of aggregates, you can switch easily from the basic configuration of 80 cubic meters to the configuration of 180 cubic meters.

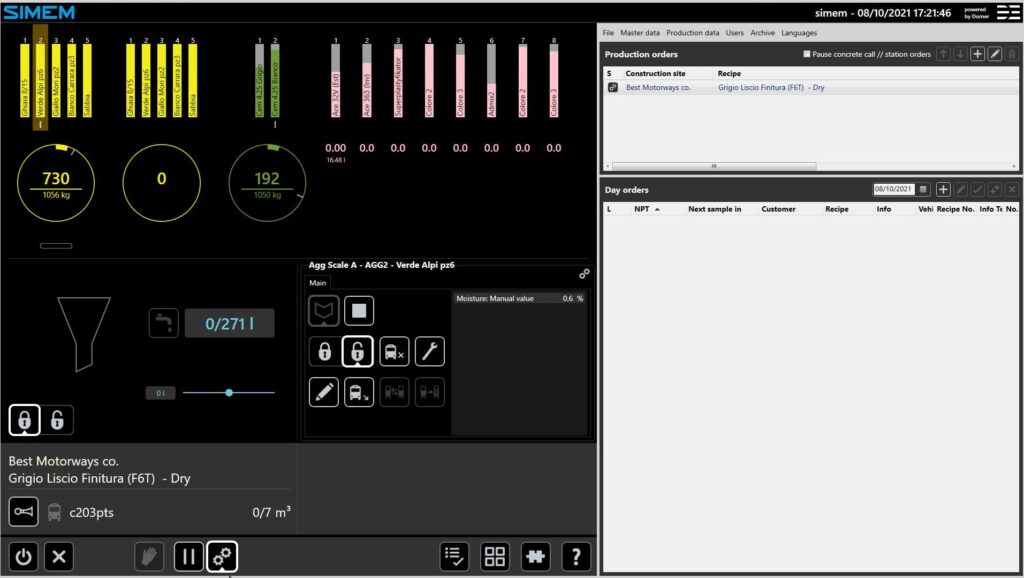

Automation - Simem@tic 3.0

SIMEM@TIC is an automation control system with a friendly interface that displays all essential plant operation information. A full process sequence view (loading, weighing, recipe, discharge, washing, production listing, pending orders) with self-adjusting software for a predictable and repeatable outcome. All production data is recorded and stored in SQL database format providing detailed record of concrete production.