The construction sector, considering both material production and building activities, is responsible for about 37% of global CO₂ emissions related to energy and industrial processes (source: IEA), making it one of the most polluting industries worldwide.

This situation is due to several factors:

Production and Transportation of Raw Materials

Huge amounts of CO₂ are emitted during the production of materials such as cement and steel, which are often transported over long distances.

Industrial Processes Difficult to Decarbonize

Producing cement, steel, and lime releases significant CO₂ not only due to energy use (often fossil-based) but also because of intrinsic chemical reactions: for example, the calcination of calcium carbonate to produce clinker inevitably releases large amounts of CO₂.

High Temperatures

Clinker production kilns operate at very high temperatures (>1400 °C), as do steel foundries (which exceed 1400–1500 °C). Such temperatures are hard to achieve with renewable sources or conventional electrification.

Materials Difficult to Replace

Cement, steel, aluminum, and glass have unique properties (strength, durability, structural safety) that make large-scale substitution with low-impact alternatives complex.

Growing Demand

Global urbanization and infrastructure development drive continuous growth in the sector; therefore, a percentage reduction does not translate into an absolute reduction.

Decarbonization Technologies Still Immature or Expensive

Solutions such as carbon capture and storage (CCS/CCUS), green hydrogen, or new low-emission binders are promising but not yet scalable or economically competitive on a large scale.

What Initiatives Have Been Activated by Concrete Industry Players?

Major industry institutions, particularly the European Cement Association (CEMBUREAU) and the Global Cement and Concrete Association (GCCA), have long been studying how to address the problem structurally, implementing integrated policies in collaboration with leading global players.

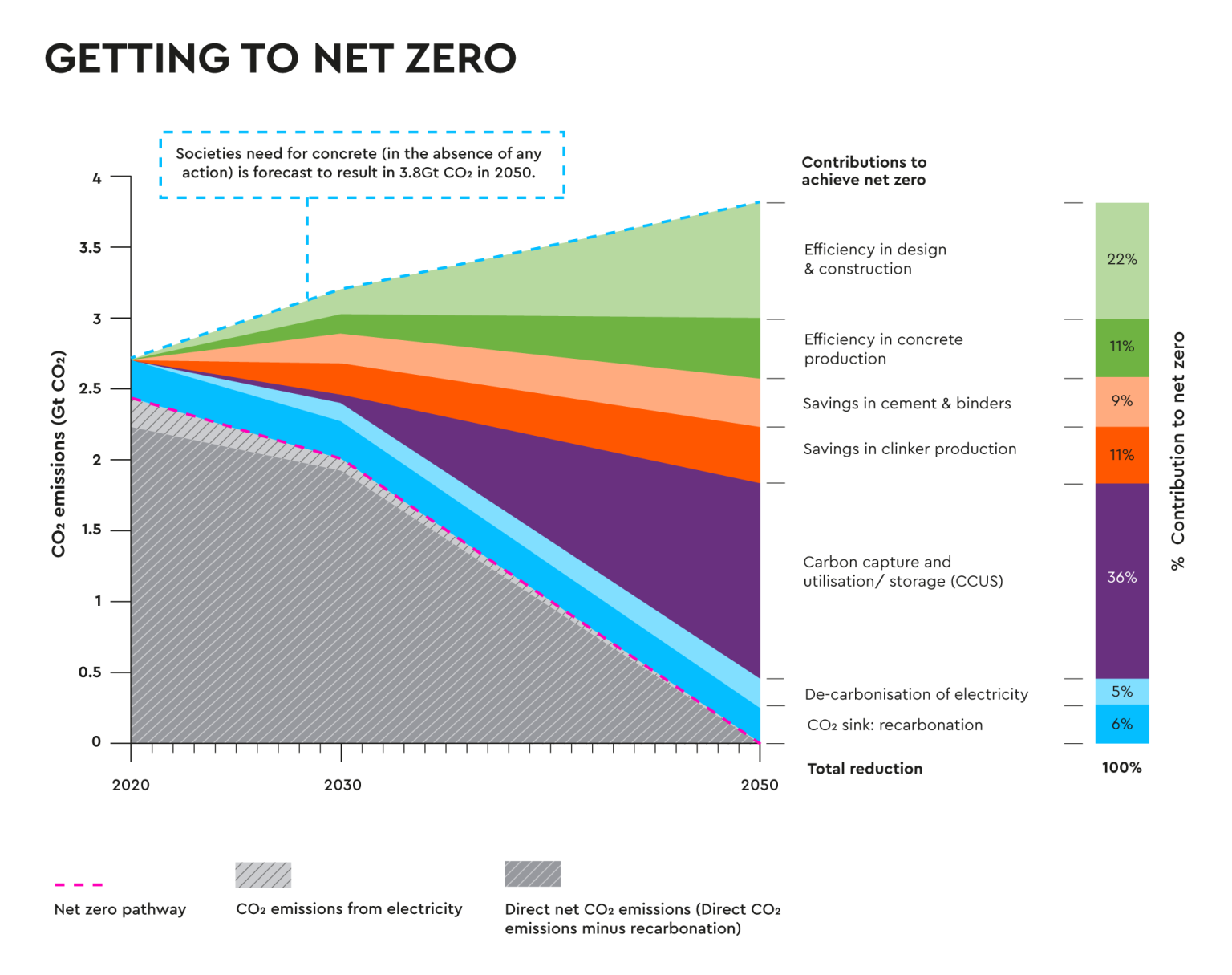

GCCA’s stated goal is “Net Zero” CO₂ emissions—achieving zero emissions in concrete production by 2050. But how?

There are various areas in which industry institutions want to take action, and for this reason they have created a roadmap that illustrates the different points of activity.

Specifically, the goal is to improve the design of production machinery as well as the process to limit emissions as much as possible; or to reduce the use of clinker (the polluting element of cement) and save on electricity.

The most significant fact, however, is that almost 40% of the actions that would make it possible to achieve zero emissions are represented by CCUS: carbon capture, utilization, and storage.

CCUS is a set of technologies aimed at capturing CO₂ from industrial processes to use it in new and different processes or to store it for the coming centuries or millennia.

The challenge is obviously difficult, ambitious, and not without obstacles: many of the technologies are still under development or not yet ready, and the applications are still at the research level.

Moreover, from an economic point of view, which is certainly not negligible, carbon dioxide is still seen as a waste rather than a resource, and therefore many studies, despite significant progress, remain costly and difficult to scale.

Nevertheless, there are a significant number of ongoing projects with the noble goal of contributing to this effort.

In what way could concrete be the permanent solution to lowering emissions?

As often happens, the answer lies in the question. Sequestering carbon dioxide in concrete would lock the pollutant away for centuries or millennia, preventing its release into the atmosphere.

Through the carbonation process, CO₂ reacts with calcium ions in the material, forming calcium carbonate (CaCO₃), a stable mineral that permanently traps CO₂. The advantage of this process is twofold: it not only captures CO₂ permanently but also improves the mechanical properties of concrete thanks to the formation of new mineral crystals that increase strength and durability.

In what way is SIMEM contributing to research to reduce carbon dioxide emissions?

At Simem, we aim to take it a step further: accelerating the process and increasing the volumes of captured carbon dioxide.

Thanks to decades of industry know-how and specific technologies, Simem is working from a slurry (cement + water + CO₂) to which aggregates are added. This mixing order is more efficient than simply adding CO₂ in the mixer at the final stage, allowing more chemical bonds to form per unit of time.

Moreover, the process takes place in a sealed system to eliminate environmental dispersion while enabling precise, measurable control.

The preliminary tests have delivered excellent and highly promising results, motivating us to intensify our efforts and resources to further support research. Moreover, Simem has filed industrial patents to protect the solutions under study and to strengthen its leading position in the sector.

Conclusions

The key challenge for the coming years in the construction sector will be reducing emissions without compromising quality, performance, and safety.

Reducing emissions through new tools must go hand in hand with investing in research and development to create integrated solutions that capture and manage emitted CO₂.

Innovations like those developed by Simem demonstrate that it is possible to transform concrete from an emissions source into a sustainability tool, making a tangible contribution to the transition toward zero-impact construction.