DESIGN

. Pumping Systems

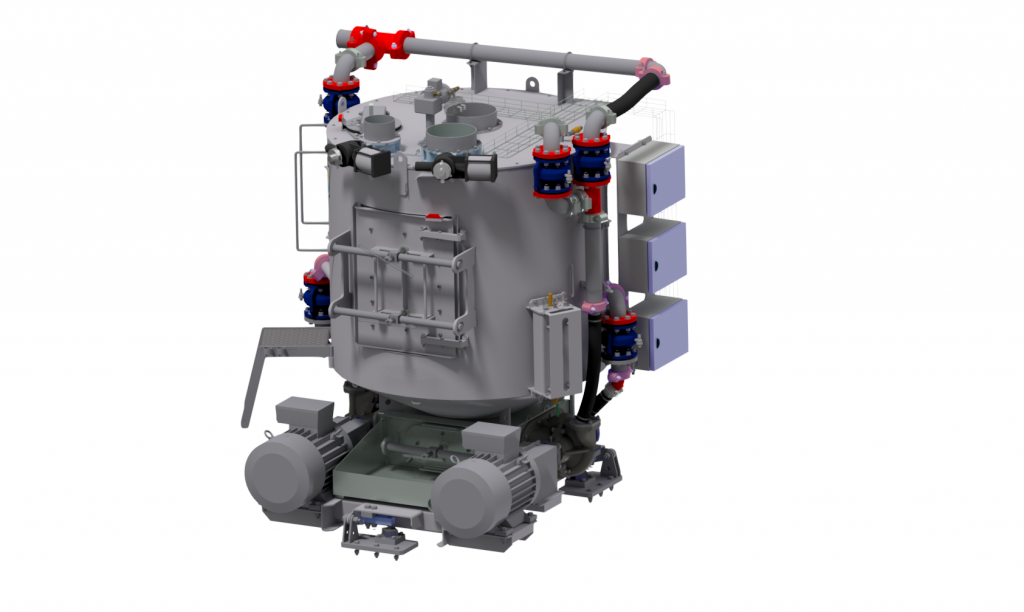

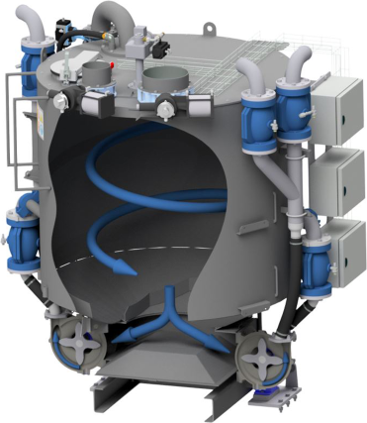

Simem Underground Solutions, and its decades of experience with long-distance pumping of bi-component grouts, cellular concrete, and hydrated bentonite, and cement slurries designs and assembles complete systems guaranteed to perform.

DESIGN

. For all Applications

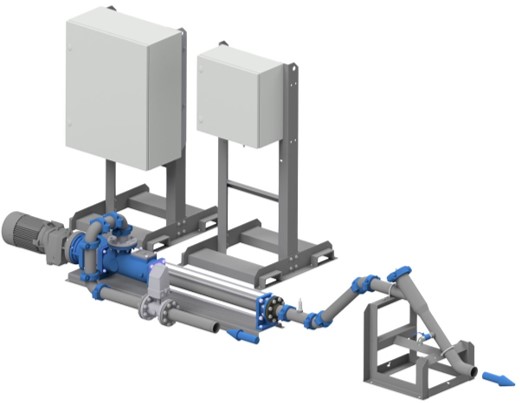

Systems are prepared for field connection as independent components, skid-mounted, or fully containerized. Applications for use in ,TBM’s, injection grouting, soil mixing, and slurry walls.

DESIGN

. Complete Systems

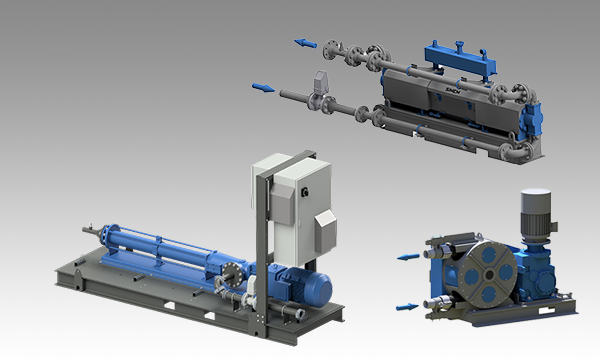

System types incorporate piston, peristaltic, progressive cavity, centrifugal, and air-diaphragm pumps. System come complete with associated power control units, instrumentation, and pipe cleaning assemblies.

Auxiliary Equipment Available

- Hydraulic Power Units

- MCC Panel

- Pump Seal Flush Systems

- Magflow Meters

- Pressure Traducers

- Pipeline “pig” Launchers