DESIGN

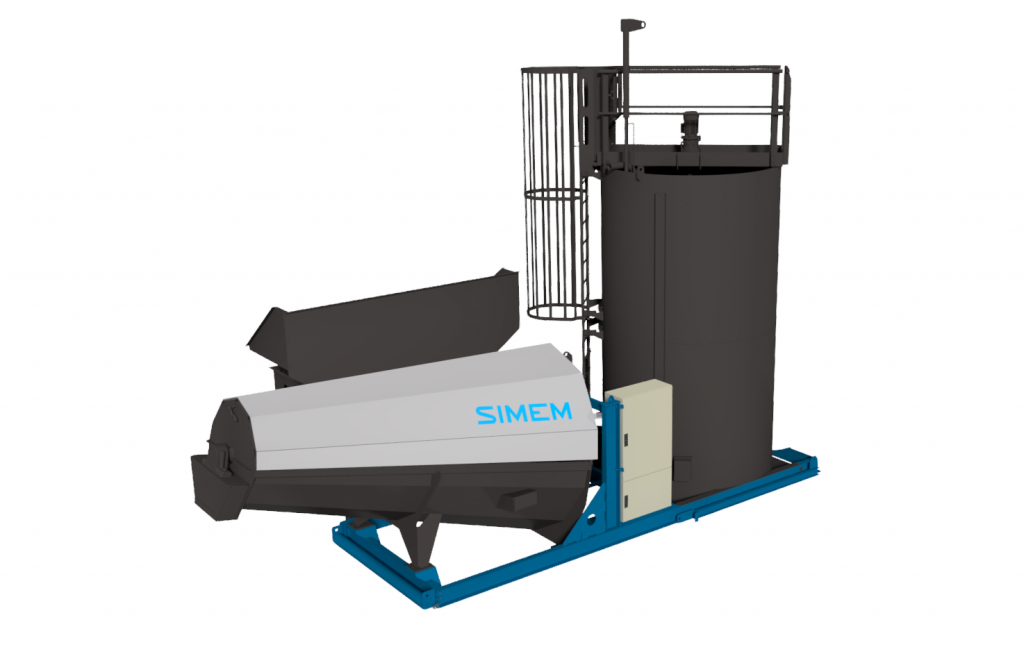

. An Innovative Design

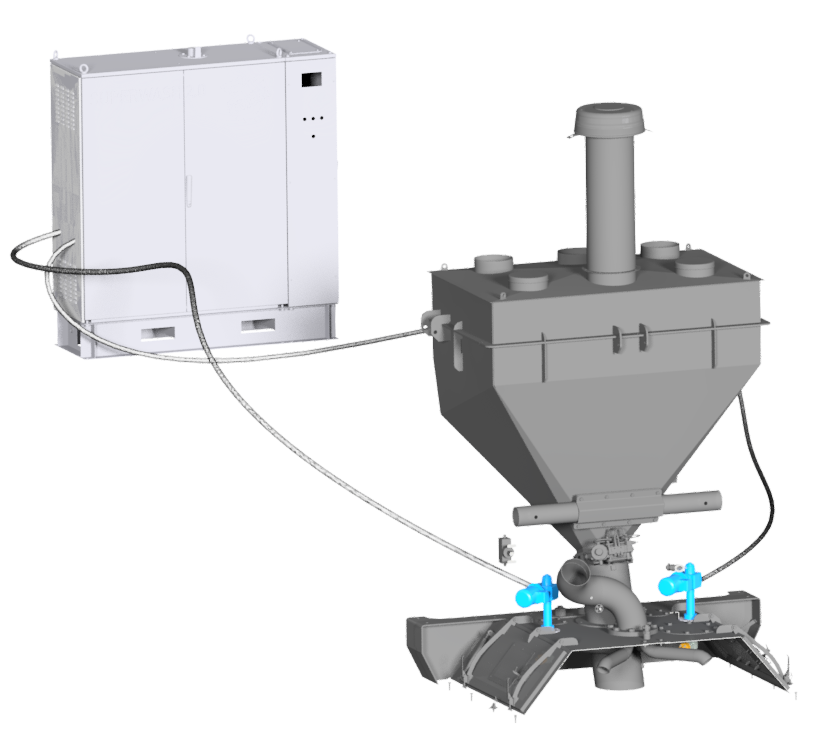

SUPERWASH: AUTOMATIC MIXER CLEANING SYSTEM.

Mixers are treated to a near 200 bar/3,000 psi providing unmatched cleaning leaving minimum residual concrete remains in the mixer tank. Simem exclusively designed orbital high-pressure rotating wash heads are self-retracting and driven by an independent gearbox and electric motor.

DESIGN

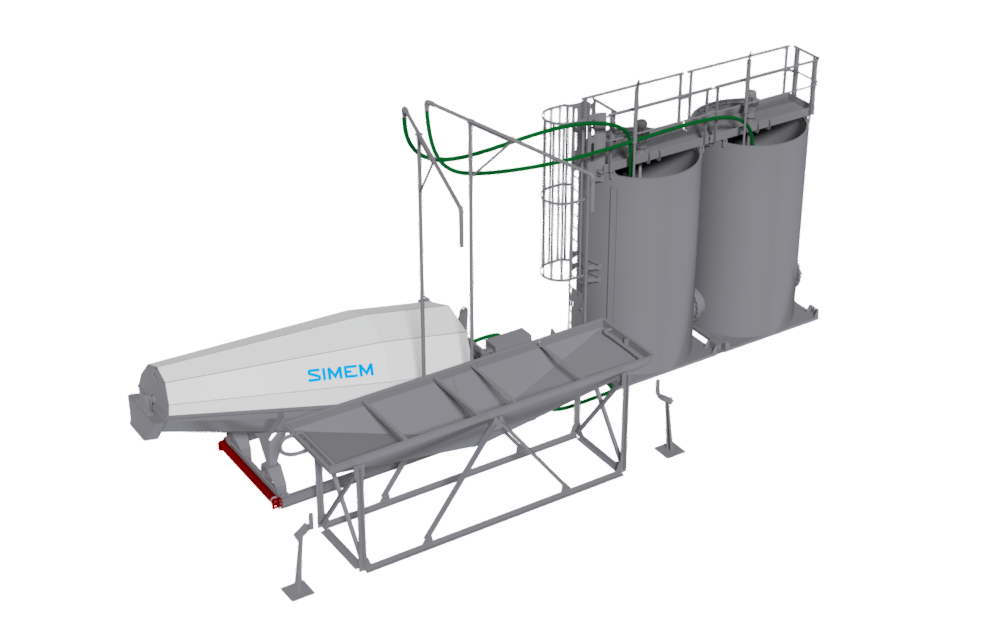

. A Complete System

Our SUPERWASH includes

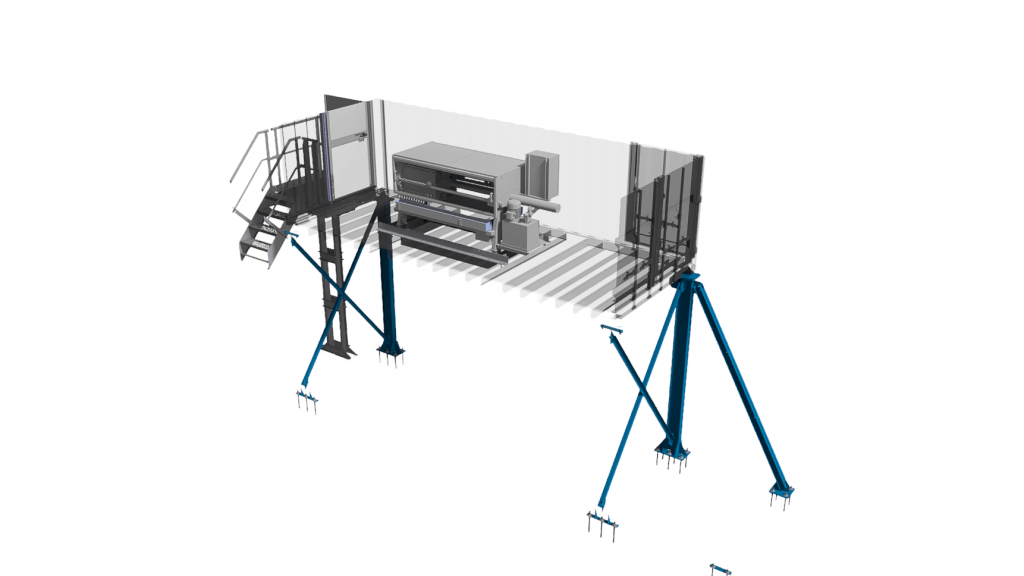

- High pressure unit, preassembled in a steel cabinet

- High efficiency water filter

- Two high pressure water pumps

- Water distribution

- Manual washing wand

- MCC power control board

- PLC connected with 3-inch control panel installed on the front door

- “Total stop” function by PLC

- Leak detection system