DESIGN

. Exclusive Design

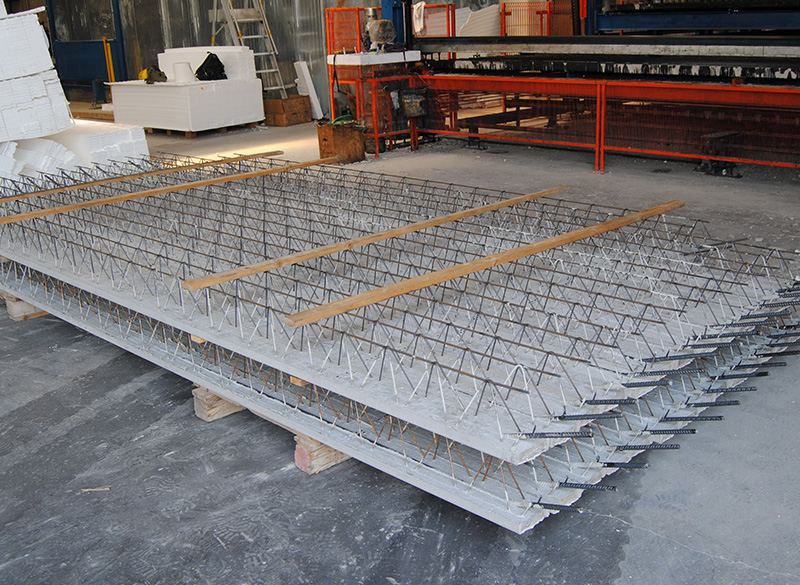

Born from the SIMEMSPIL expertise in automated carrousels, BRICKBEAM is a brick-cement beams and lintels system and brick-cement lattice girder beams.

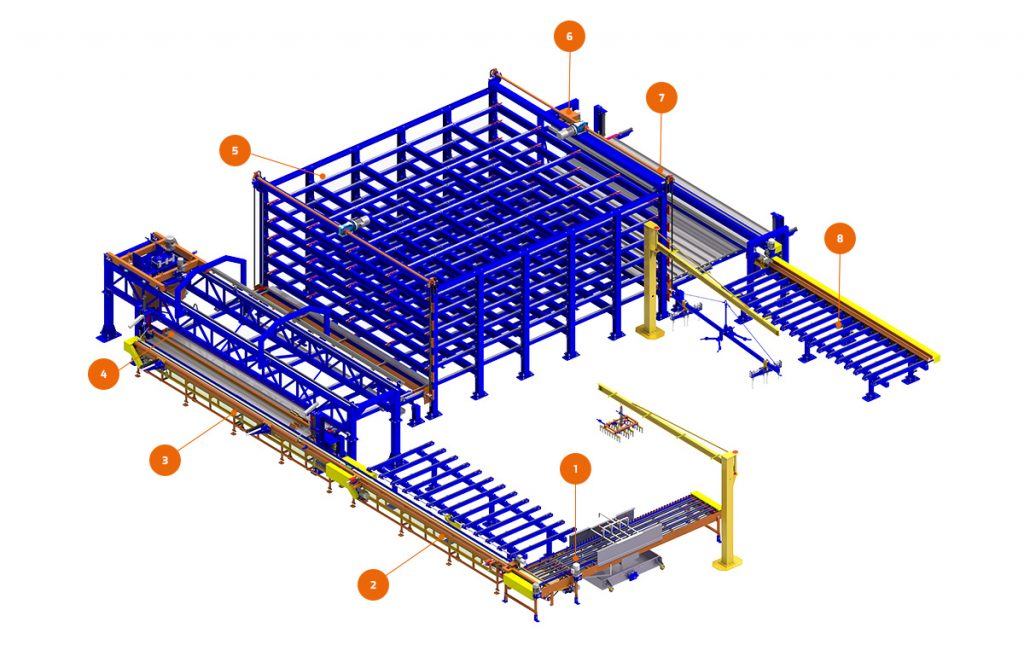

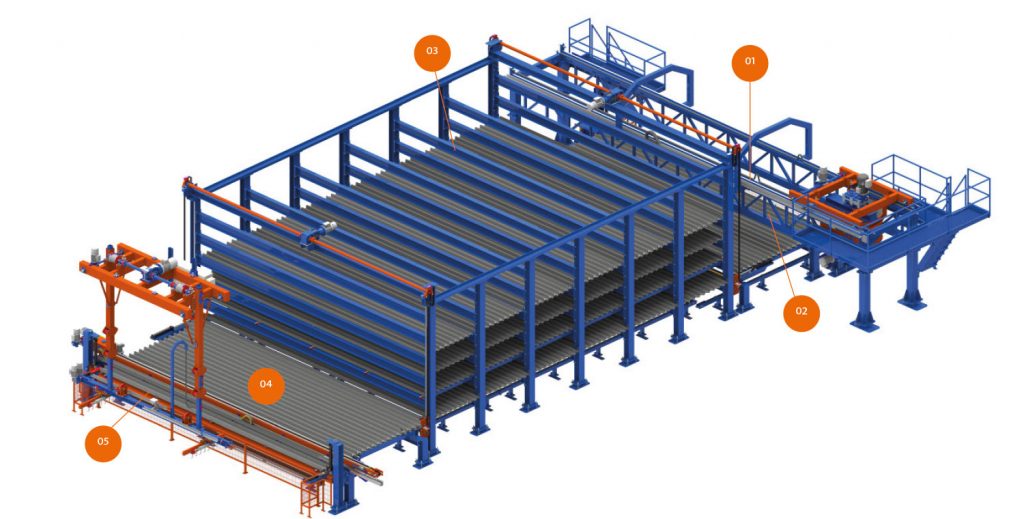

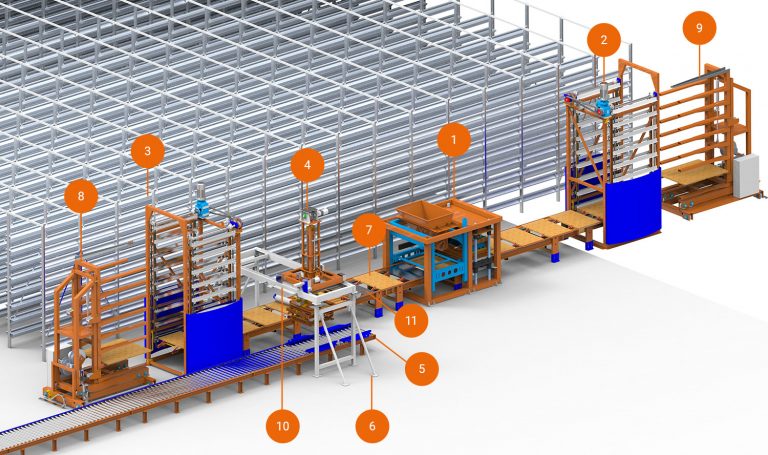

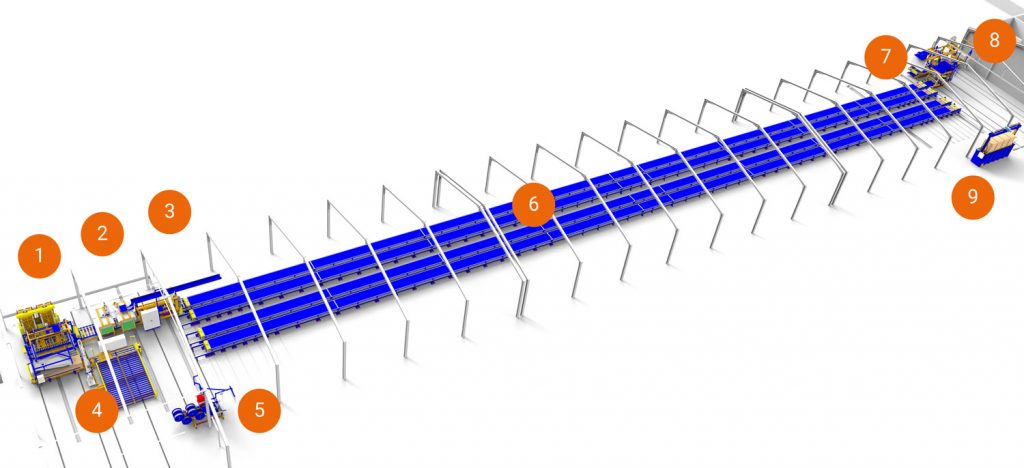

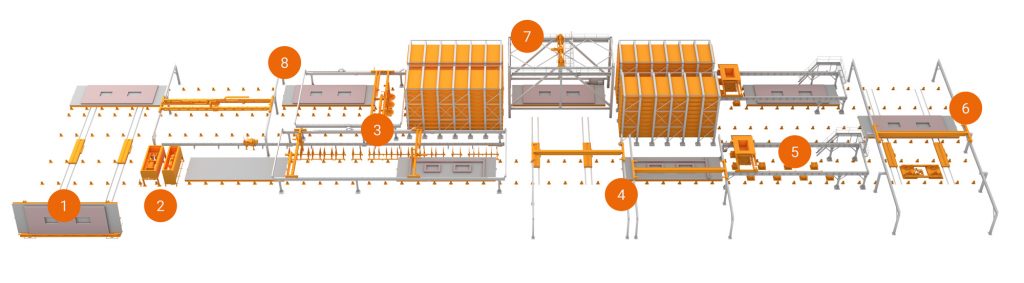

DESIGN

. Layout Legenda

- Brick feeder with jib crane for manual loading.

- Feeding line of bases and reinforcement.

- Initial head including elevator for empty trays

- Casting and vibrofinishing station

- TOWER curing magazine

- Demoulding station

- Final head with automatic station for recovering the cleaned trays

- Unloading line with jib crane for manual stacking