Granted performance up to 600 ton/h

Perfect weighing accuracyaccording to UNI EN 206-1 Concrete quality

Reduced installation time with hydraulic self erection system: no crane needed

Minimal environmental impact suitable to operate within any site restriction

Transport on any roads: no special permissions needed

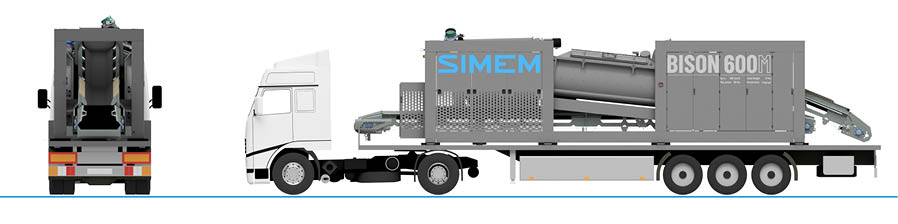

The travelling mixing solution - Bison

The Bison range of concrete plants is a range of super mobile machines that have reached levels of capacity and quality far superior to the rest of the market. The Bison range represents the result of the union between Simem’s experience in the world of concrete with in-depth technical studies. Compact and easy to transport, Bison is perfect for those who need mobility and speed of installation from one site to another.

Application

HEAVY CIVIL CONSTRUCTION

• Roller Compacted Roller – RCC

• Concrete pavements (airports,

channels, etc)

• S2 quality concrete (Innowet system)

PAVING AND ROAD BASEMENT

• Cold asphalt mox

• Cold recycled asphalt

• Foamed bitumen mix

• E-concrete

INERTISATION

• Solid waste treatment

• Stabilisation of contaminated soils

• Treatment of industrial sludges

• Special application (woodchip)

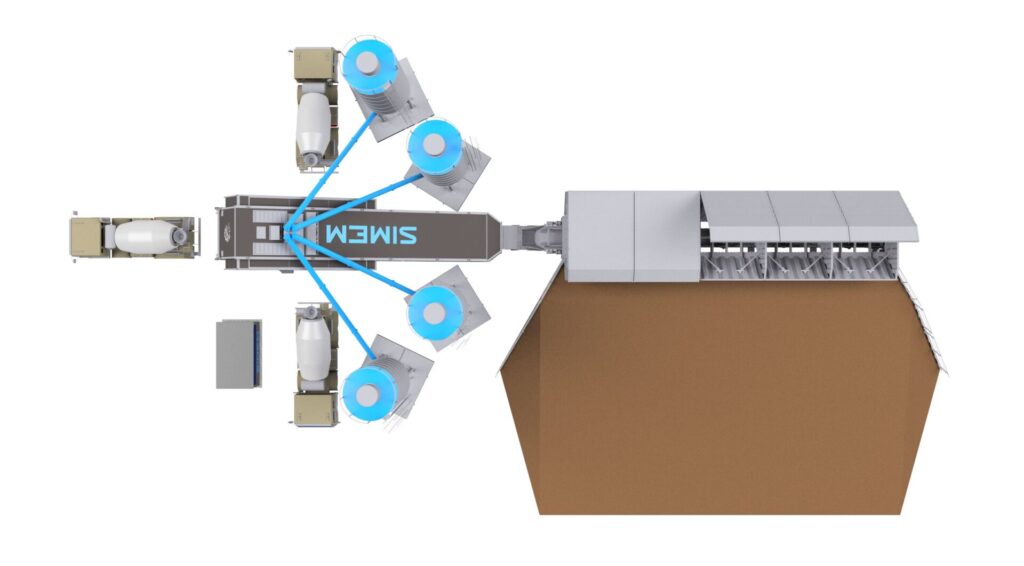

Mobile unit

- Trailer Mounted Mixing & Batching Unit

- Hydraulically Powered Plant Set-up – No Cranes Required

- Aggregate Hopper 19.6 cy /15m3 Capacity (divider optional)

- Hot-Dipped Galvanized Steel Structure

- SIMEM@tic FLOW Intuitive Automation

- Weight based Cement & Aggregate Metering System

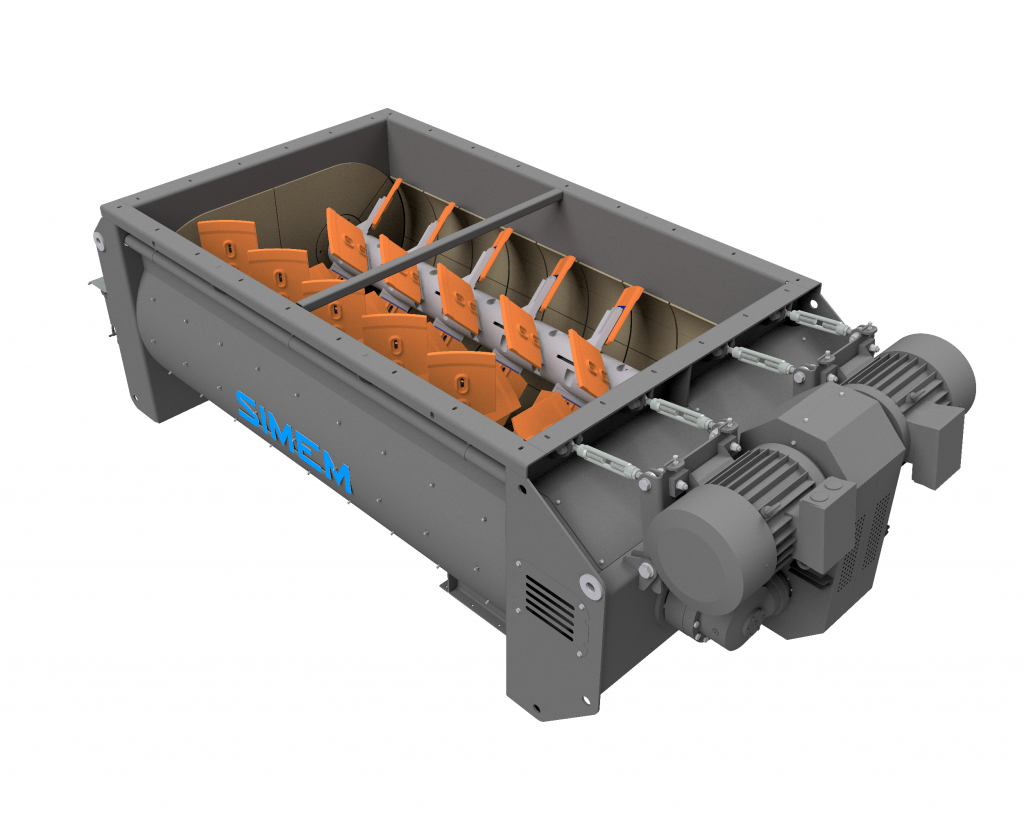

Continuous mixing - MDC

- Adjustable Mixing Retention Time

- MDC Twin shaft continuous mixer

- Electric Drives

- Bolted Mixing Paddles

- Bolted Mixing Arms

- Adjustable Mixing Arm Configuration

- Practical Wear Liner Replacement

Modularity

BISON models are expandable – in addition to silos, service unit and aggregate extension unit with hot-dipped galvanized structure and retracting loading ramp panels include an independent load cell metering and dosing system for each bin, and transports via flat-rack trailer. This level of mobility allows for simple relocation and easy layout configuration to fit varying project conditions where continuous mixing operations thrive!

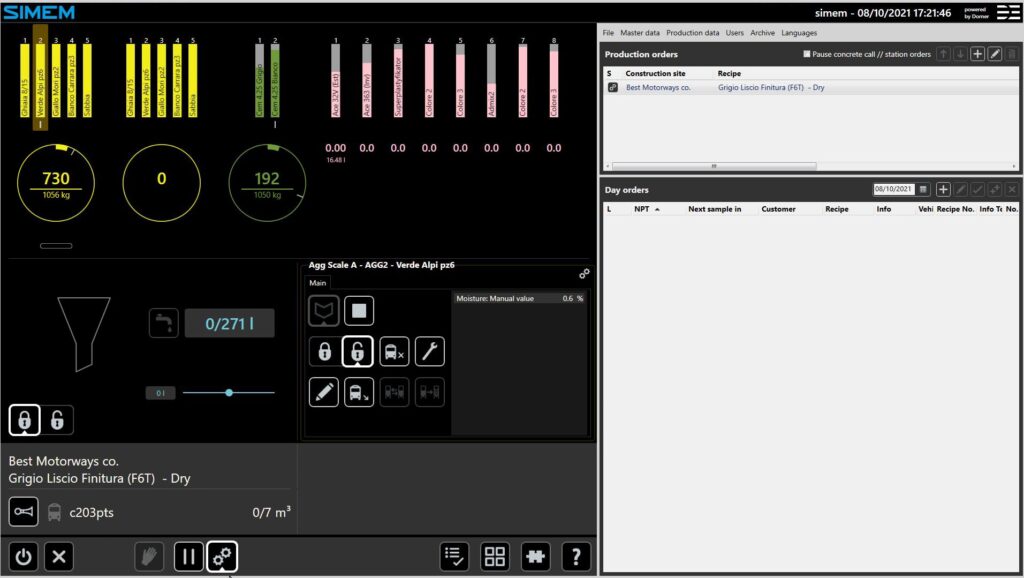

Automation - Simem@tic flow

The super mobile Bison plant provides a dosing precision comparable to a batching plant, thanks to the continuous cement dosing system, developed with the Politecnico di Milano University.

• Industrial PLC solution connected to industrial PC with 24” wide

screen and printer

• Immediate indication on video of plant actions and actual

performances

• Real time flow correction with % for each product

• Safety change settings and parameters

• Periodic back-up of all system and production data.

Easy Transport

Thanks to the hydraulic legs the transport is easy and can be disposed with one standard truck. Bison can be transported on any road without special permissio

MAIN TRAILER

(twin shaft mixer, 1 aggregate, powder and liquid dosing devices, loading belt)

POWDER UNIT

(silos, screw conveyors, compressor and filter)

SERVICE UNIT

(control cabin, generating set, water storage tank)