DESIGN

. The travelling mixing solution - Bison

The ideal solution for projects requiring mobile operations, accurate weighing of multiple aggregates and powders, including cements and fly ash.

The Bison 500 plant can precision mix up to 500 tons per hour in continuous production. Bison 250 will mix up to 250 tons per hour in continuous production.

The main unit of the Bison plant can be ready in just a few hours.

Applications include: RCC (Roller Compacted Concrete), Pavements, Cement-Treated Bases, Soil Stabilization Mixes.

DESIGN

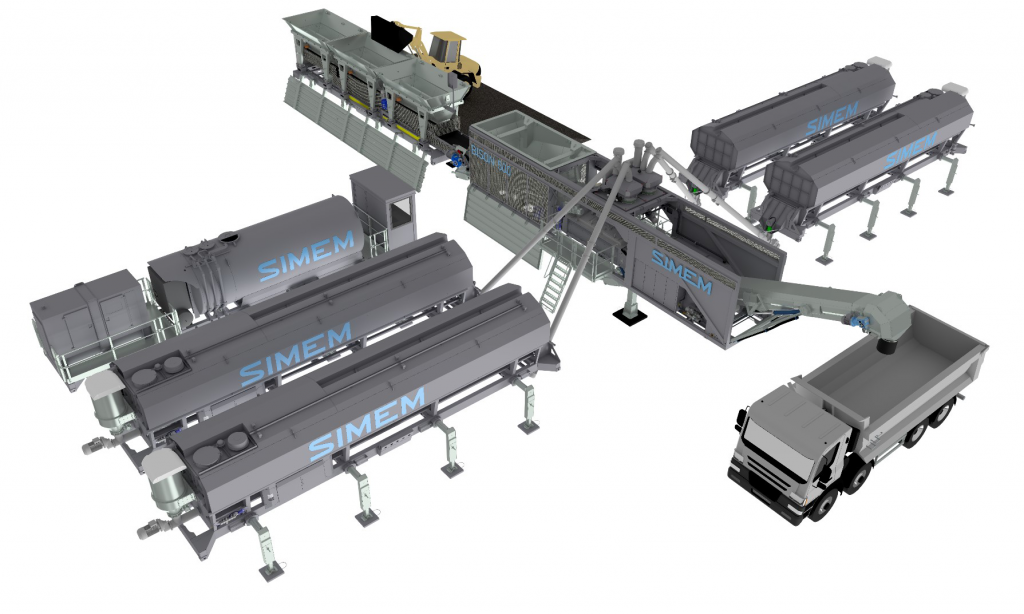

. Plant Overview - Mobile unit

- Trailer Mounted Mixing & Batching Unit

- Hydraulically Powered Plant Set-up – No Cranes Required

- Aggregate Hopper 19.6 cy /15m3 Capacity (divider optional)

- Hot-Dipped Galvanized Steel Structure

- SIMEM@tic FLOW Intuitive Automation

- Weight based Cement & Aggregate Metering System

DESIGN

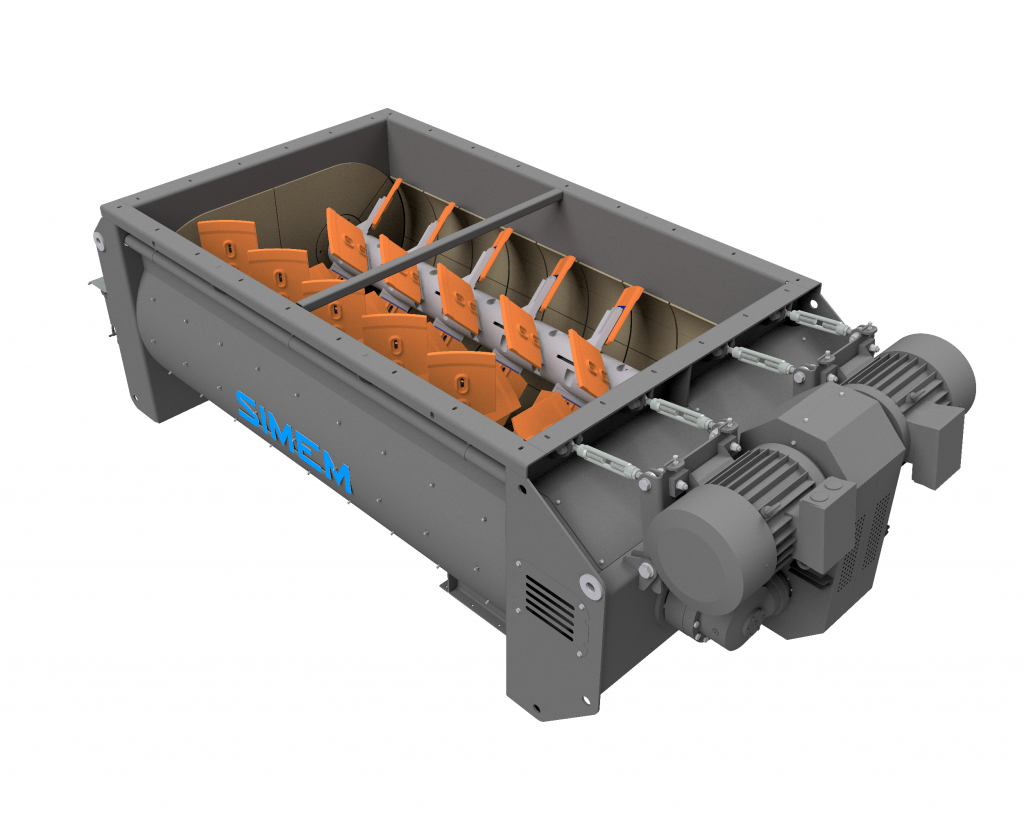

. Continuous mixing - MDC

- Adjustable Mixing Retention Time

- MDC Twin shaft continuous mixer

- Electric Drives

- Bolted Mixing Paddles

- Bolted Mixing Arms

- Adjustable Mixing Arm Configuration

- Practical Wear Liner Replacement

DESIGN

. Plant Overview - Modularity

BISON models are expandable – in addition to silos… service unit and aggregate extension unit with hot-dipped galvanized structure and retracting loading ramp panels include an independent load cell metering and dosing system for each bin, and transports via flat-rack trailer. This level of mobility allows for simple relocation and easy layout configuration to fit varying project conditions where continuous mixing operations thrive!

DESIGN

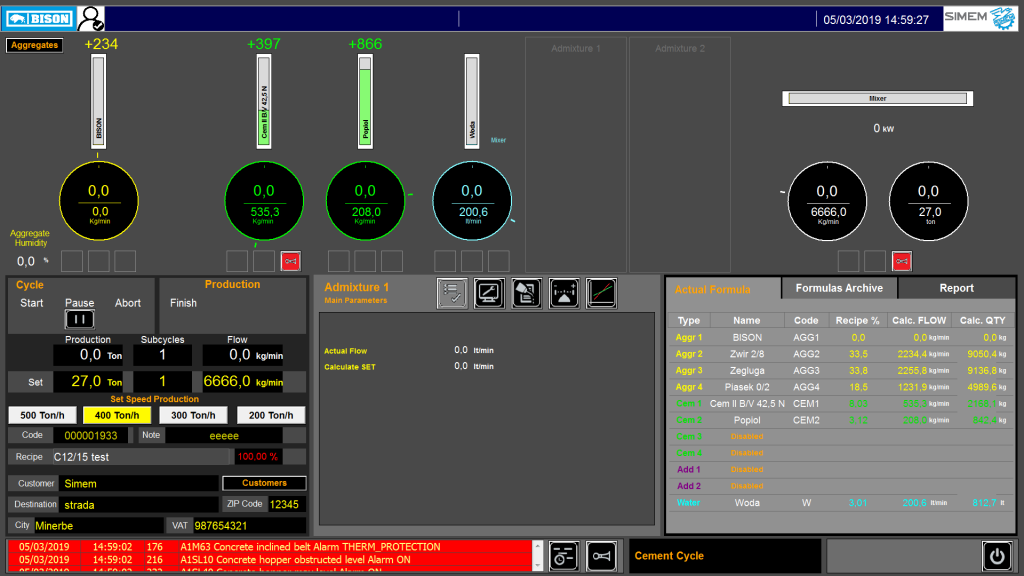

. Automation - Simem@tic flow

Simem@tic Flow is an easy to use automation with unbeatable accuracy and flexibility for uninterrupted operation.

- Familiar Windows operating environment with SQL database

- Flexible reporting and backup functionality

- Real time flow correction for each material

- PC/PLC based