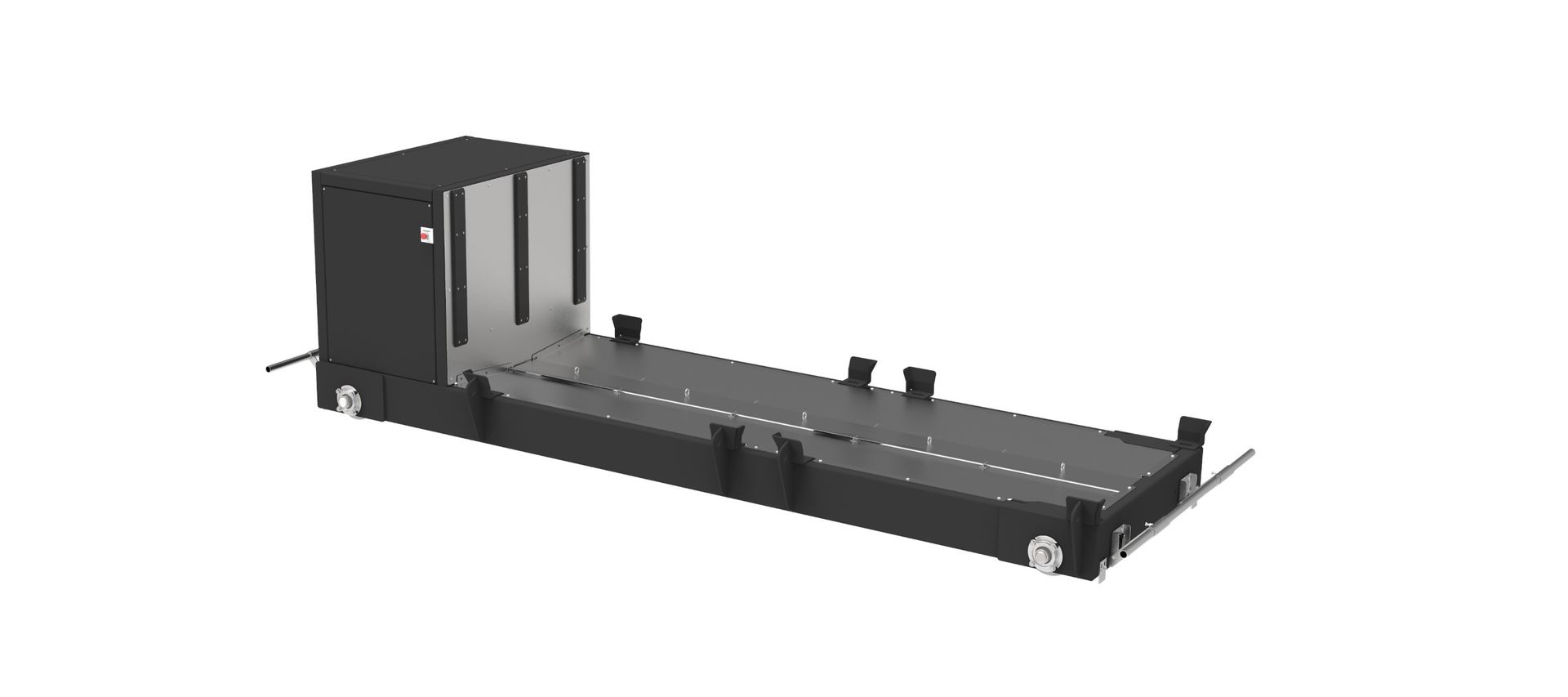

A NEW RECLAMATION SYSTEM

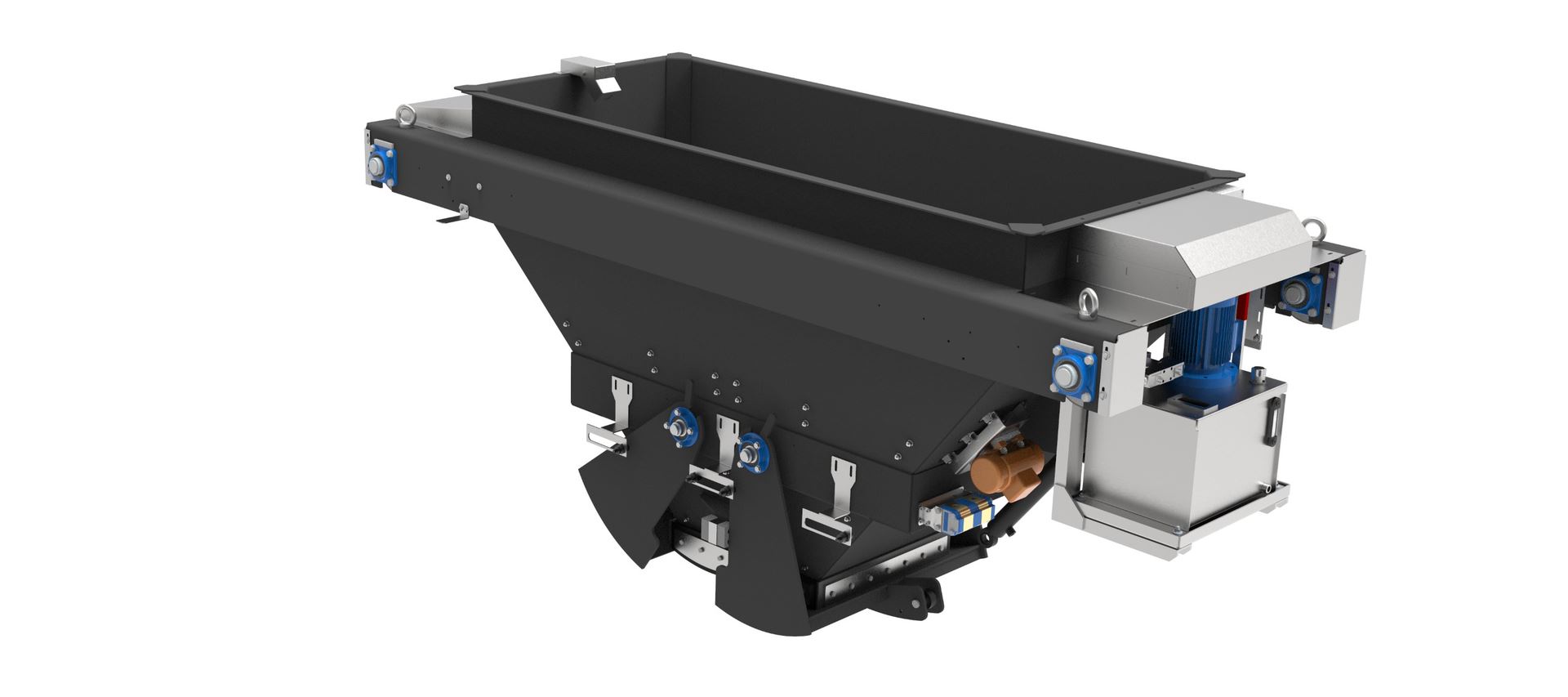

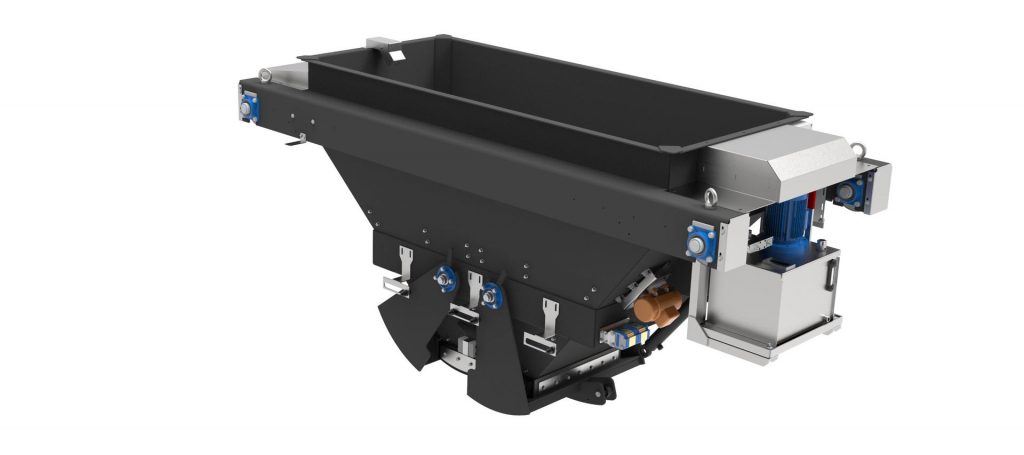

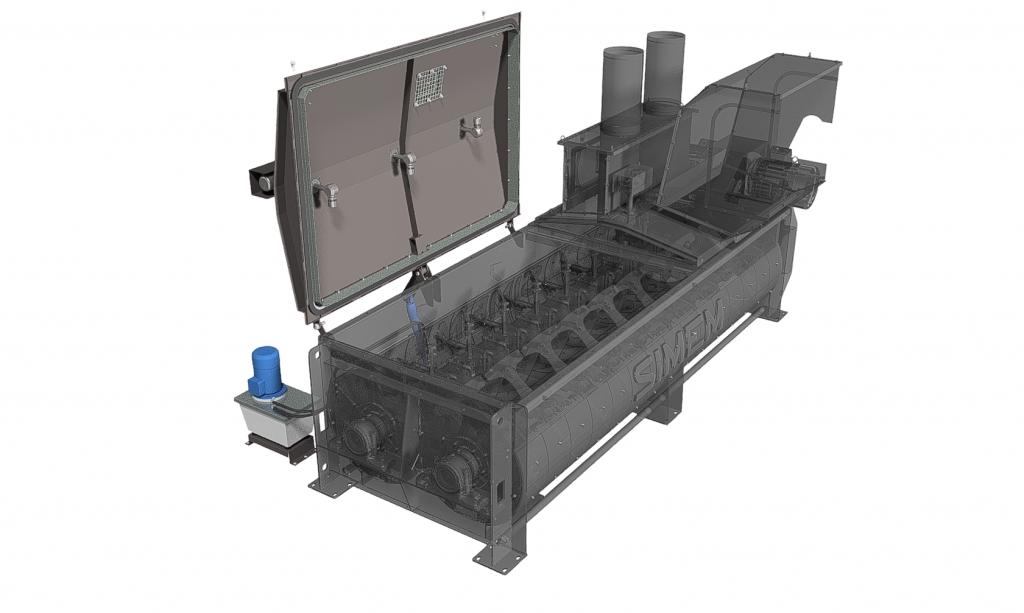

BETONWASH is the definitive solution for reclamation of excess concrete and slurry water from cleaning of trucks, pumps, mixer, buckets, etc.

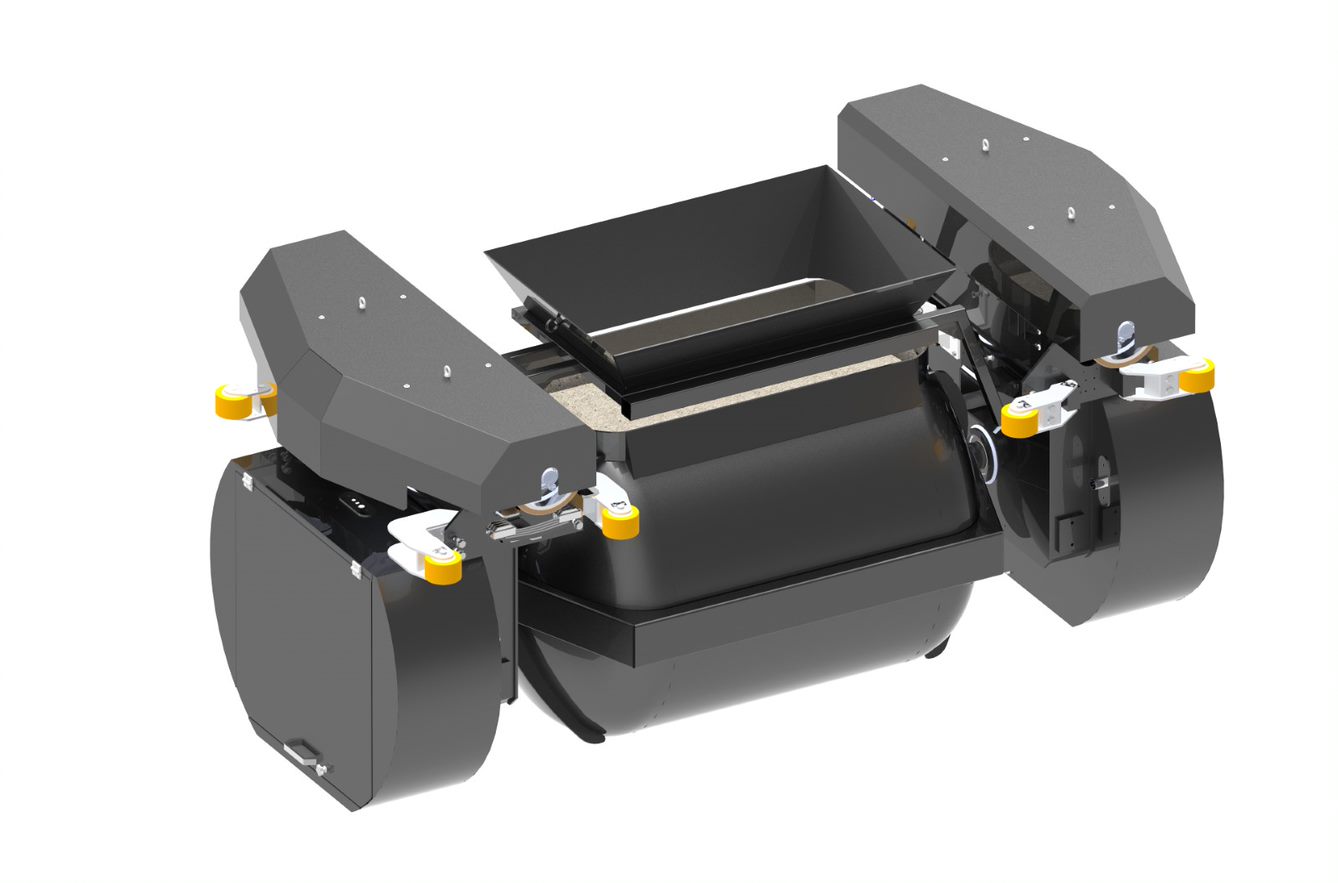

It separates solid materials over 0.15 mm diameter from the water through a spiral system rotating inside the inclined drum.

Slurry water is discharged from the BETONWASH by overflow into storage tanks and can be reused in the production of concrete or pumped into the WATERWASH.

WHY CHOOSING BETONWASH

Some advantages that make the BETONWASH the best choice are:

- Extraction of solid materials through a spiral system without the use of any filters often found in reclamation systems.

- Two models available with capacity of 10 or 25 m³/hour.

- Concrete can not get in contact with the drive unit ensuring mechanical integrity.

- Minimal wear of surfaces inside the inclined drum thanks to the low rotation speed, the extraction spiral and the use of residue aggregate as a wear liner.

- With a wide variety of possible configurations, BETONWASH will fit any plant and site

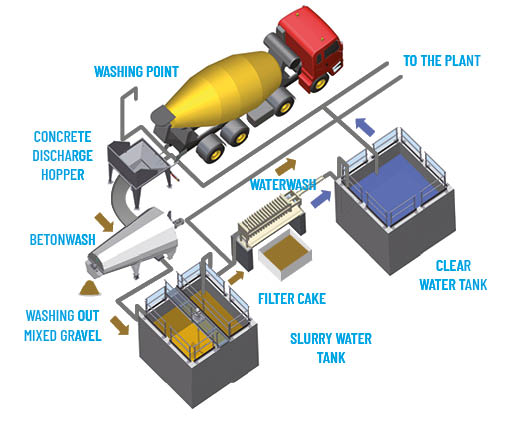

HOW DOES THE WHOLE SYSTEM WORK

1. The process begins with the mixer or truck washout.

2. Extra concrete is diluted with clean water through pipes

3. The diluted concrete is discharged into the hopper, equipped with conveying pipes

4. BETONWASH works automatically until the complete extraction of aggregates (up to 0.15 mm)

5. The system periodically starts the agitator to avoid the settlement of fine materials

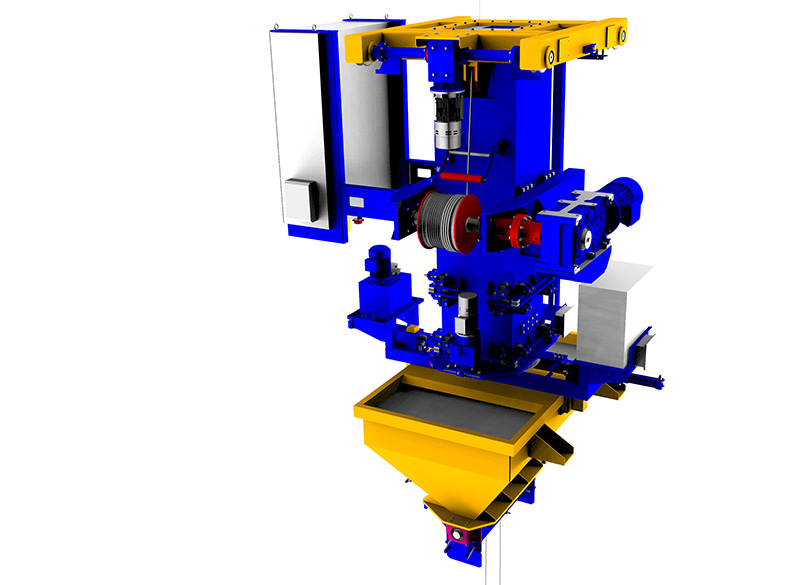

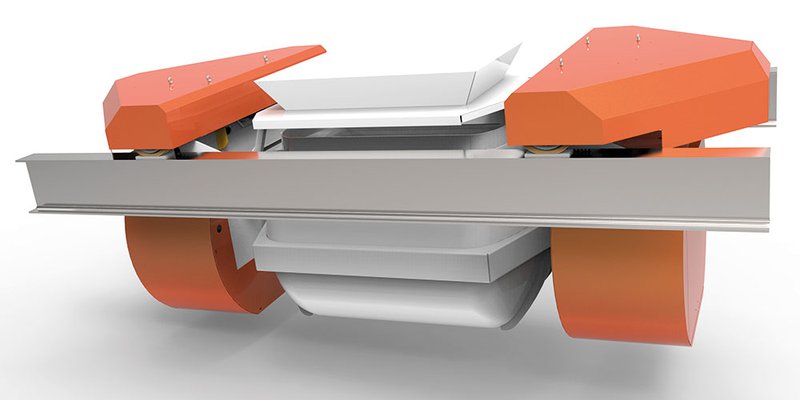

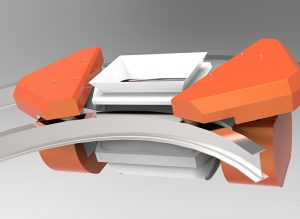

6. Slurry water is received from the WATERWASH from a specific deposit tank

7. WATERWASH separates water from concrete generating a “cake” of aggregates that can be reused in the concrete production

8. Clean water can be reused in the plant for site activity

9. A PH adjustment is available to check water conditions