NEW BISON DRY

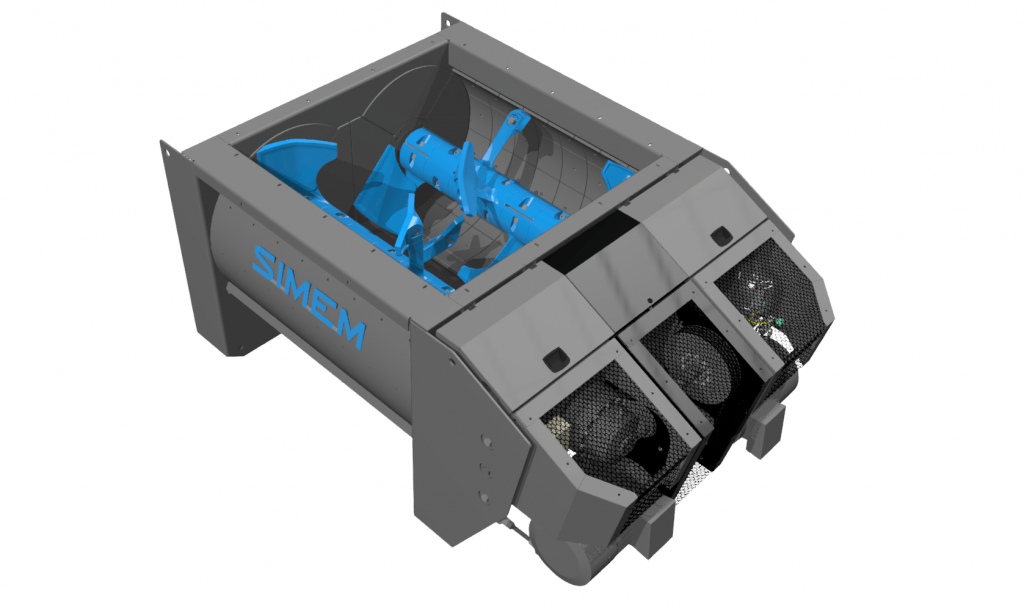

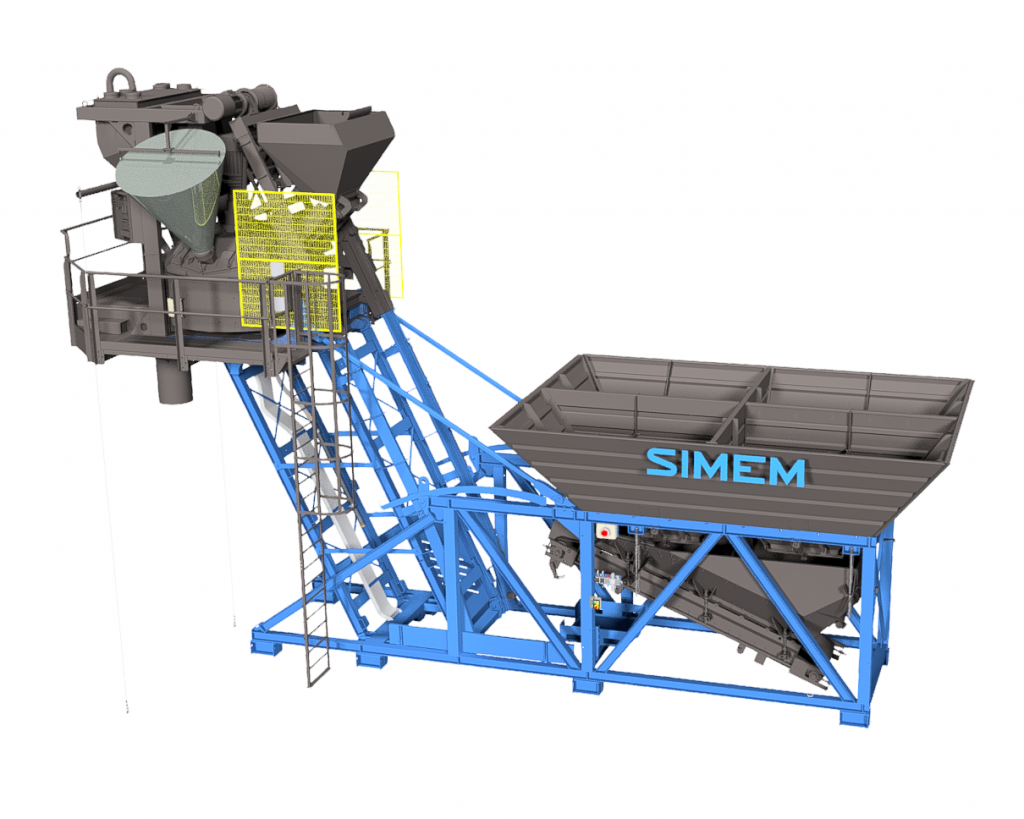

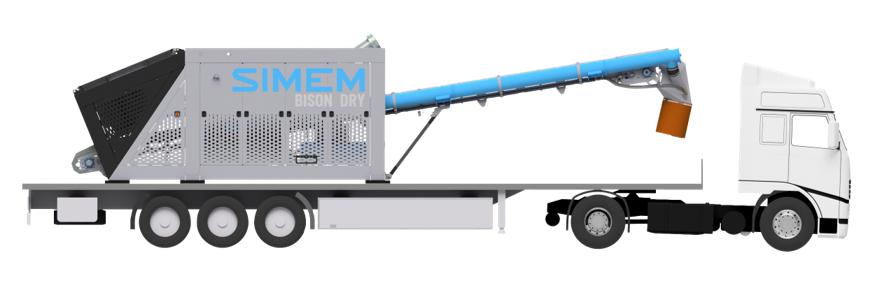

BISON DRY is the new super-mobile plant designed for dry batching in concrete production.

This plant is the ideal solution for the ready-mix sector applied to «mobile» construction sites (wind power, roads, bridges).

High productivity, modularity, extreme mobility and transport easiness are the main features.

PRODUCTIVITY

- Total aggregates capacity: up to 8 m³

- Hourly production with cycles up to 8m³ and standard recipe: up to 45-95 m³/h (based on configuration and aggregates charging time)

- High dosing accuracy

- Clear visual indications to wheel loader operator, during aggregates loading phase

MODULARITY

The new DRY range is designed with focus on modularity and configuration using different aggregates modules according to the required needs.

From 1 up to 4 aggregates.

NEXUS GROUP

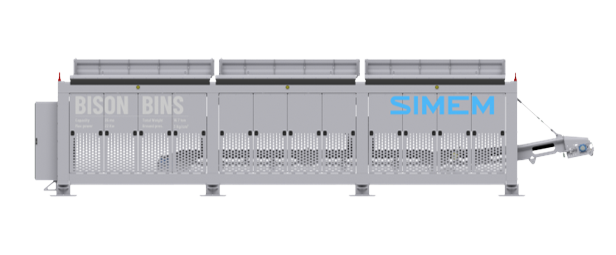

BISON BINS

BIN-ONE

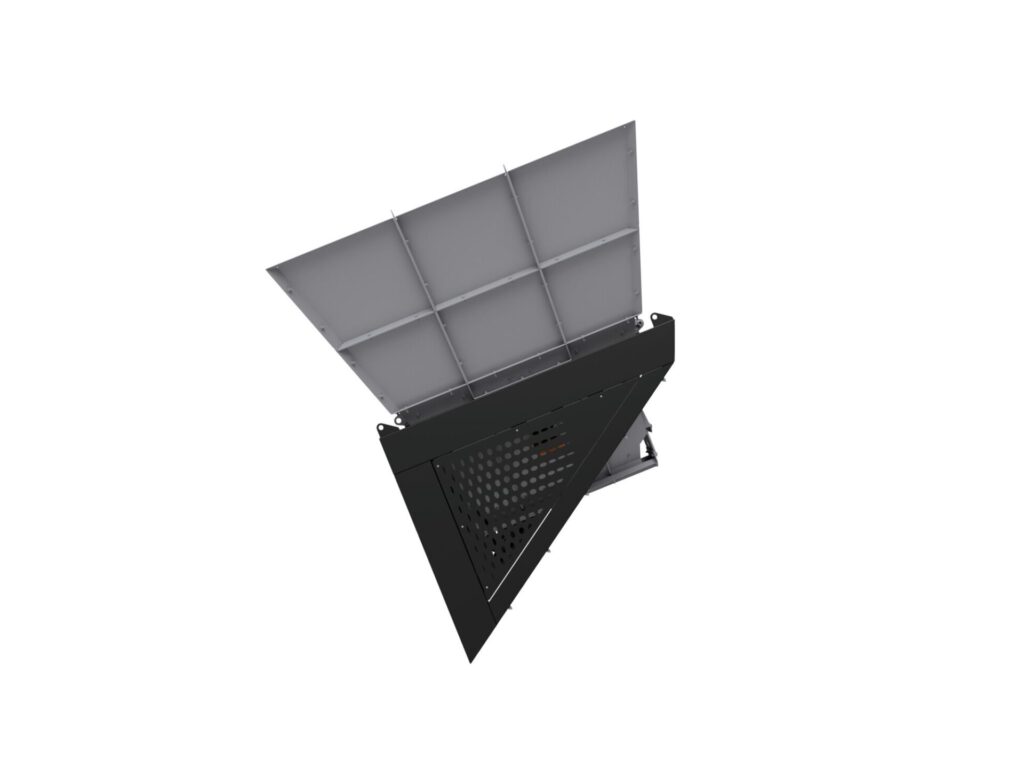

BIN-ONE: THE NEW AGGREGATES UNIT

The Bin-One aggregates weighing unit has been specially designed in combination with the new Bison Dry.

- Cumulative weighing system up to 4 aggregates

- Wide loading width and no ramp required

- Large digital display providing weighing indications to wheel loader operator

- Protection grids (optional)

EASY OPERATIONS

The new BISON DRY can be installed directly on solid ground without civil works.

Through side doors, it is possible to inspect the functional parts of the system.

Ordinary maintenance is therefore easy and safe, to keep the plant long-lived and always at maximum productivity.

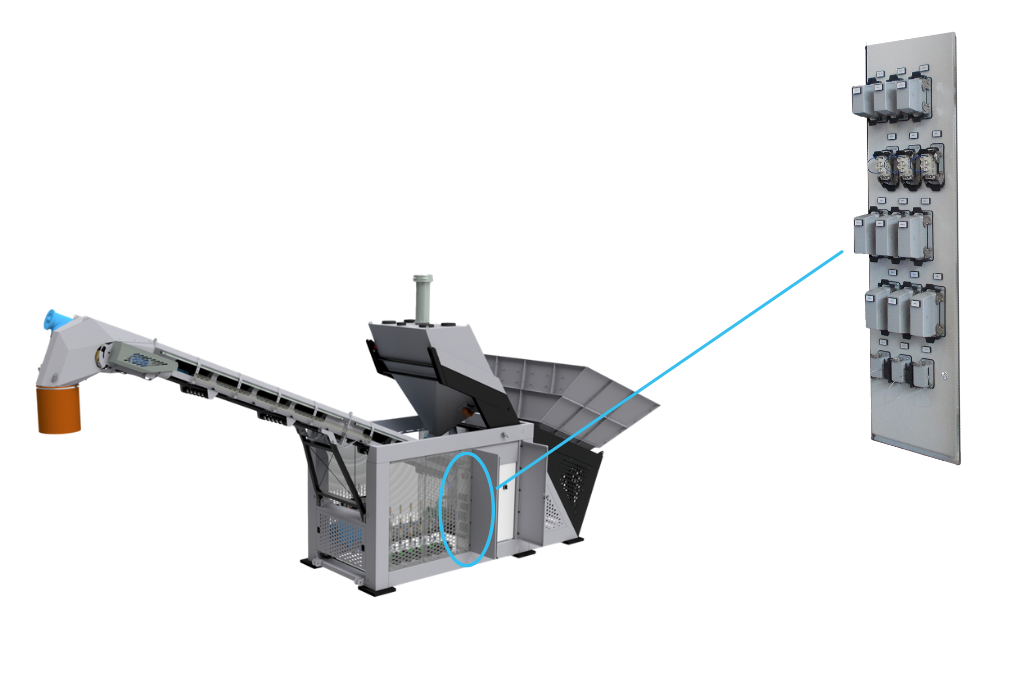

PLUG&PLAY

It reduces time for plant installation and startup, thanks to prewired plugs.

All the controls are arranged along a single electrical panel easily accessible via an inspection door.

The Bison Dry arrives on the construction site already tested and ready to be started via electrical sockets.

EASY TO TRANSPORT

The new BISON DRY can be installed directly on solid ground without civil works; hydraulic legs (optional) are available to facilitate loading and unloading from the truck.

The BISON DRY is conceived as a unit with standard truck/container size even when the integrated Bin-One is included.

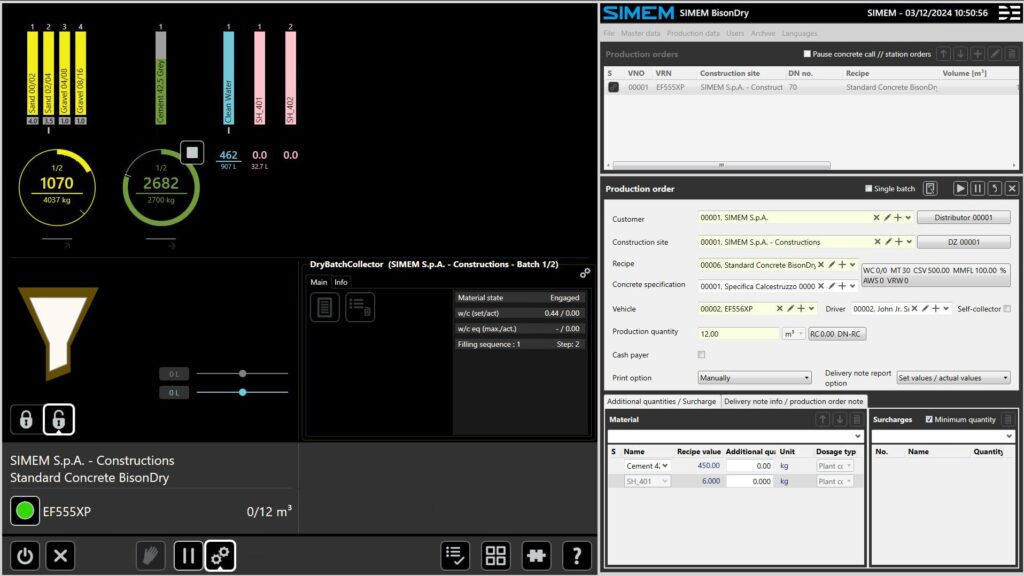

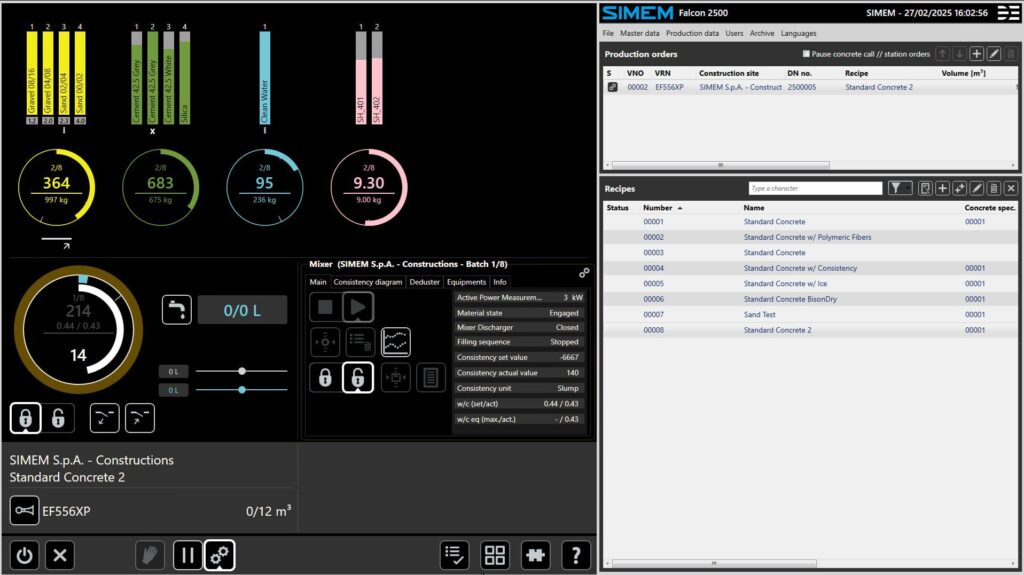

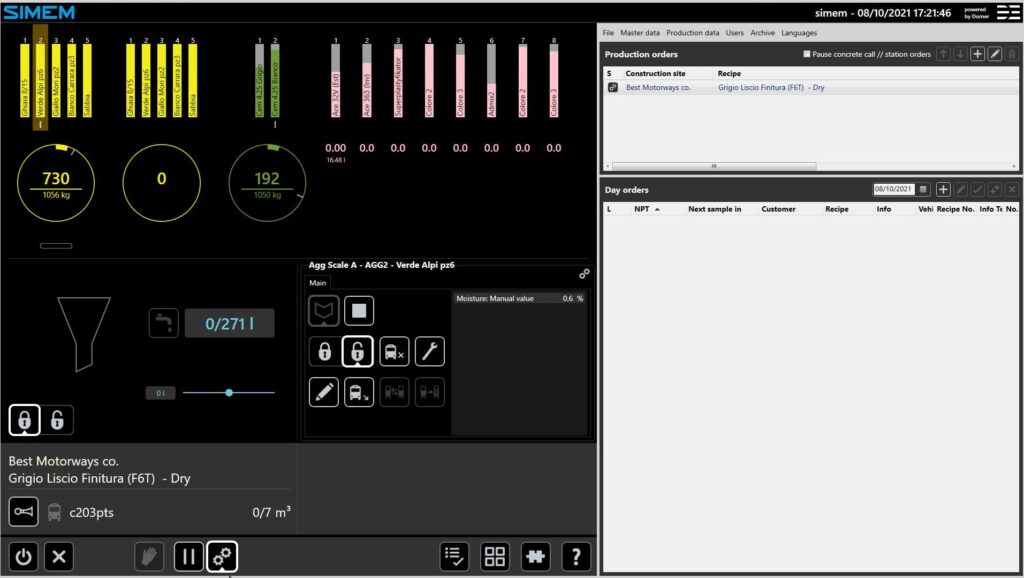

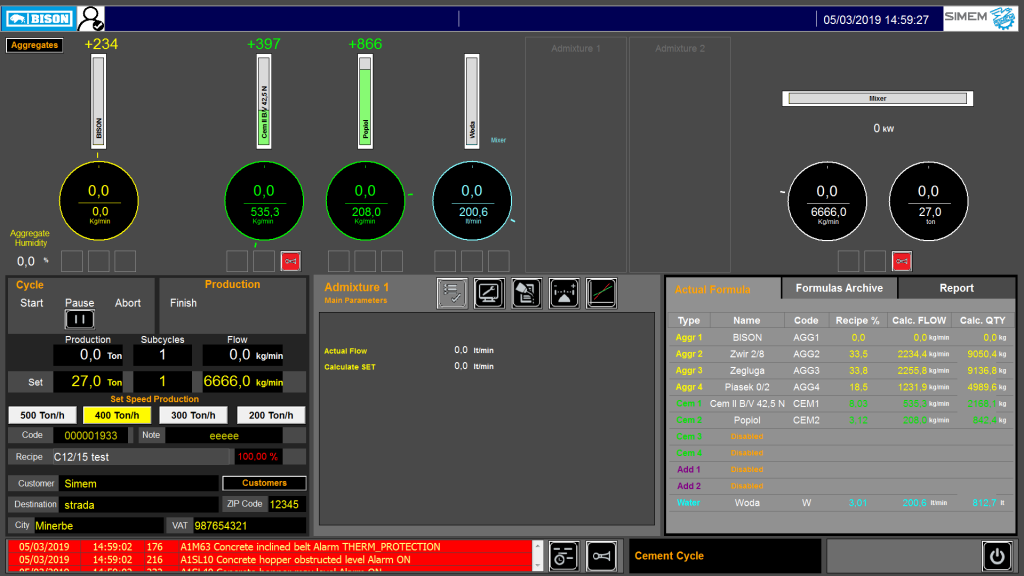

AUTOMATION – SIMEM@TIC

- Industrial PLC solution connected to industrial PC

- Immediate indication on video of plant actions

and actual performances. - Real time flow correction with % for each product.

- Safety change settings and parameters.

- Periodic back-up of all system and production data.

- Remote control for system’ service.