DESIGN

. Innovative Design

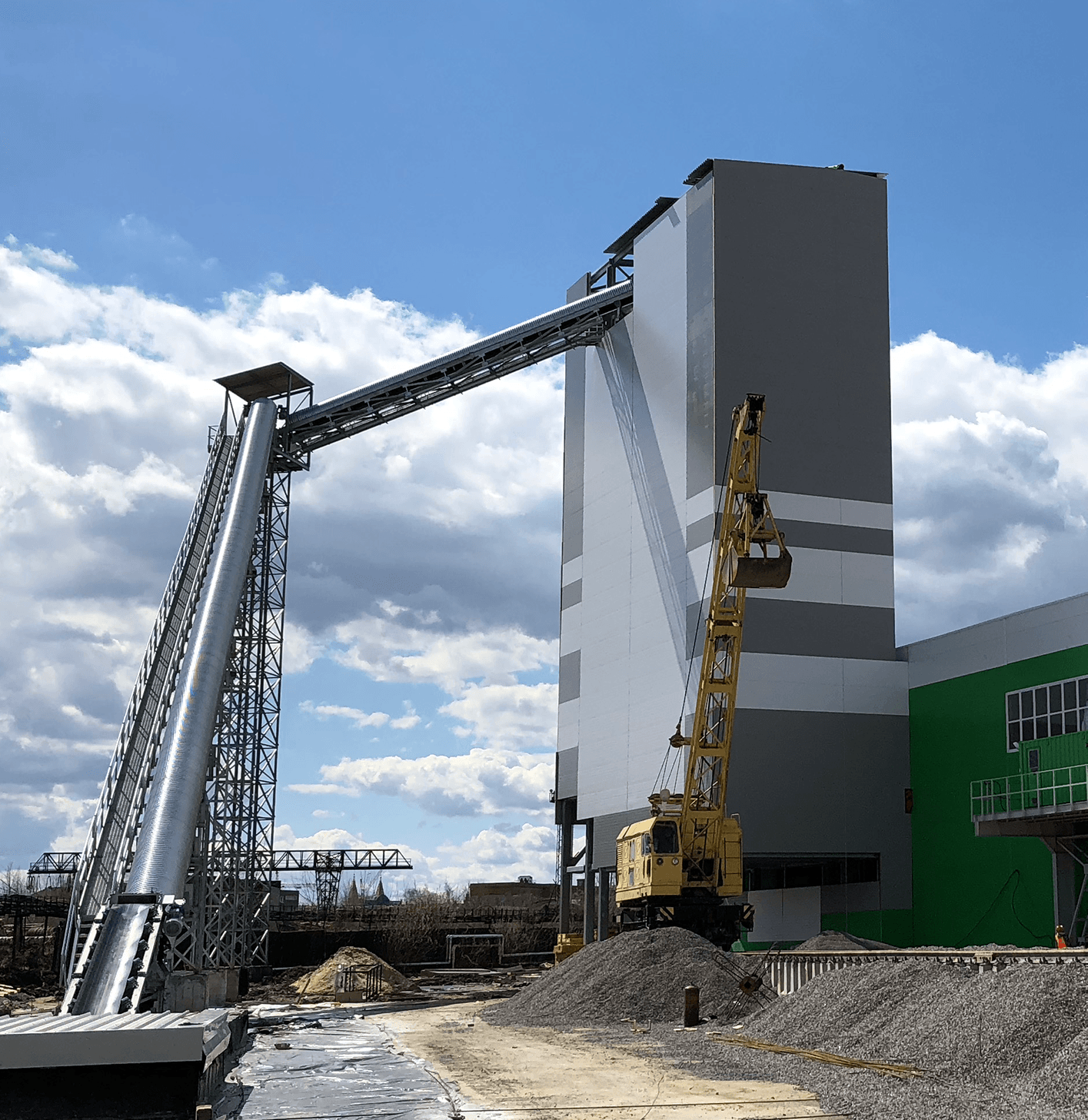

WETBETON batching and mixing plants are state of the art for concrete production. NEXUS aggregates hoppers are together with the mixer, the central component of the plant; key features of NEXUS hoppers are availability in different sizes and capacities, high modularity, possibility of expansion, high inclination of bin walls and cones (for a proper material flow), prevision for liners, full galvanization, industrial production with highest standard processes.

DESIGN

. Modularity and Flexibility

The WETBETON series represents an effective solution thanks to its modularity and excellent quality. SIMEM is able to offer a “super plant” by simply assembling standard components in special configurations, implementing multiple solutions in terms of loading points, mixer types, storage, etc., resulting in plants with large storage and production capa-cities at a very competitive cost and a small footprint. Plants that have multiple mixers with a production capacity of 720m3/h and simultaneous discharge from each mixer, along with a large storage of raw materials.

DESIGN

. Dam Projects

SIMEM experience on DAM projects goes back to 1990. Since then, a large number of Wetbeton plants have been designed and supplied for DAM projects (both RCC and conventional concrete, with large size aggregates). Plants are normally equipped with MSO twin shaft mixers, output up to 9 m3 per cycle, dosing devices for aggregates, cement, silica, and ice. Many plants have been used in projects with production up to m3 of concrete!

DESIGN

. Simem@tic 3.0

SIMEMATIC 3.0 is the automation program that, with a friendly interface, displays all the essential information about the plant for full ope-rations control (loading, weighing, recipies, discharge, production lists, pending orders)