DESIGN

. Fast Installing Patented Solution

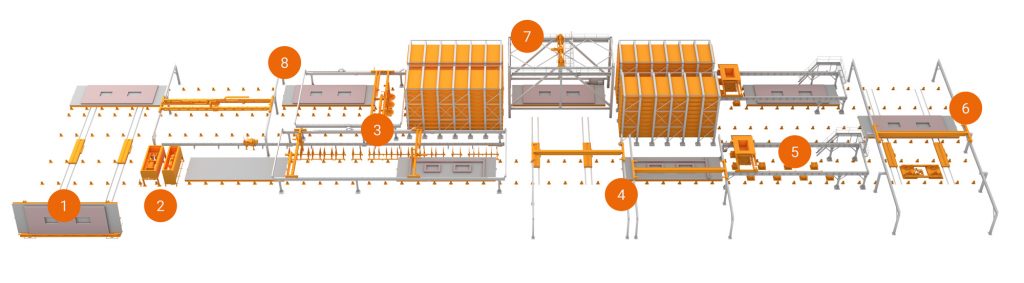

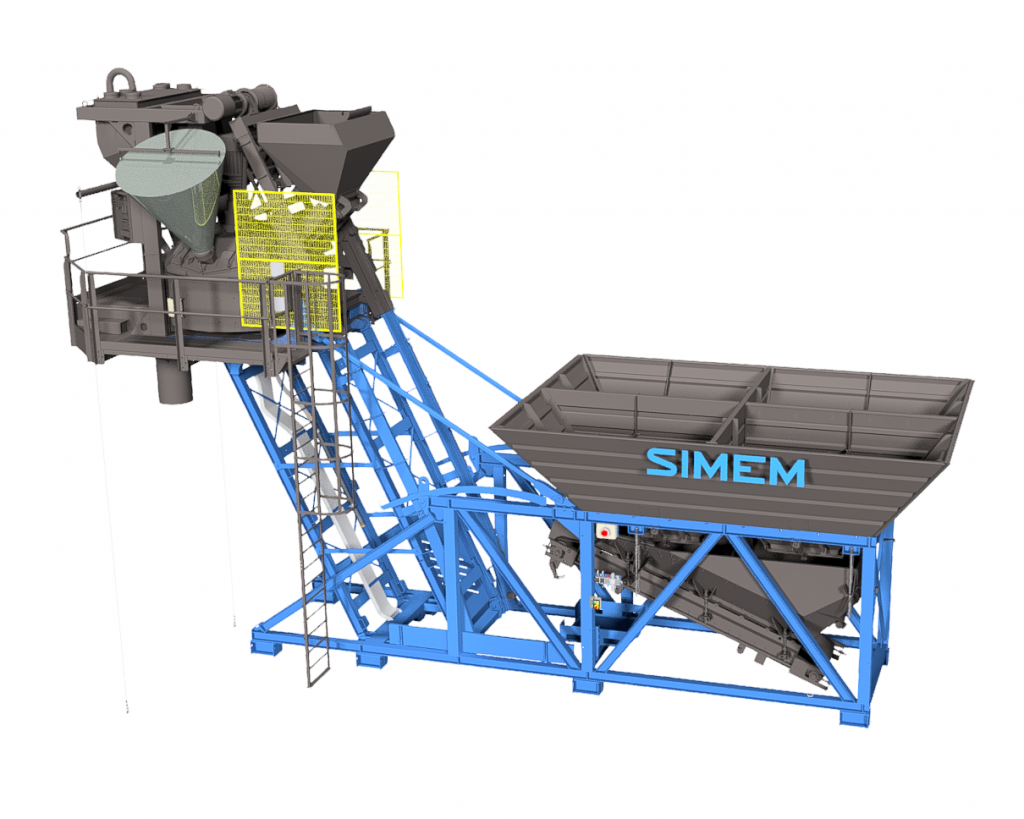

MobyMix is available in three different capacity sizes ranging from 28 yd3 up to 52 yd3 per hour. The mixing support structure features patented foldable legs and is prepared to support cement, water, and additive dosing weighers.

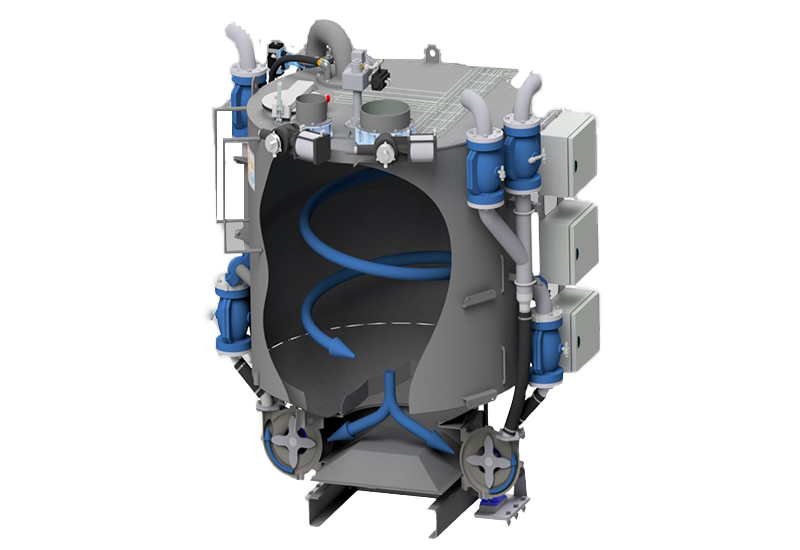

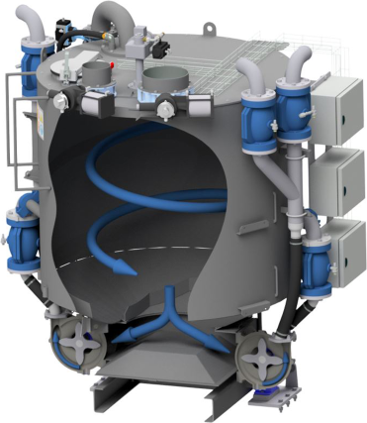

MobyMix incorporates the Simem SUN planetary mixer, equipped with a planetary gearbox vertically secured to the electric driving motor, concentrating the transmission and driving system to the center of the mixing tank.

DESIGN

. SUN Planetary Mixer

Compulsory mixing action guarantees the most homogeneous mix in minimum mixing time. Steadfast design and quality build materials allow SUN mixers to address a variety of mixing applications for various production processes. Complete plants for truck mixers to precision concrete, recasting factories, mobile plants, construction site plants, and special mixing processes (powders, waste treatment, chemical components, etc.), SUN mixers are proven performers.

DESIGN

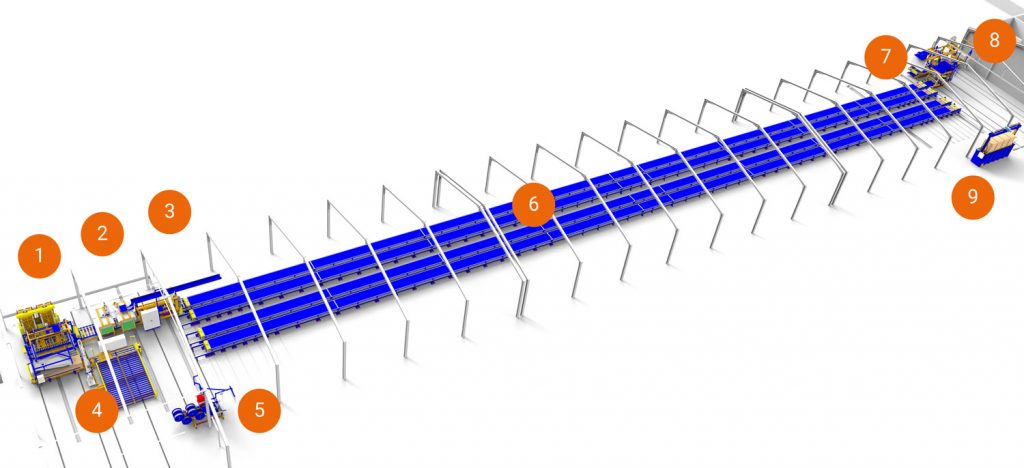

. Modularity and Flexibility

SIMEM MobyMix series can be supplied with housing, insulated or not, for the complete plant or specific parts of the plant in order to work with the toughest possible climates!

DESIGN

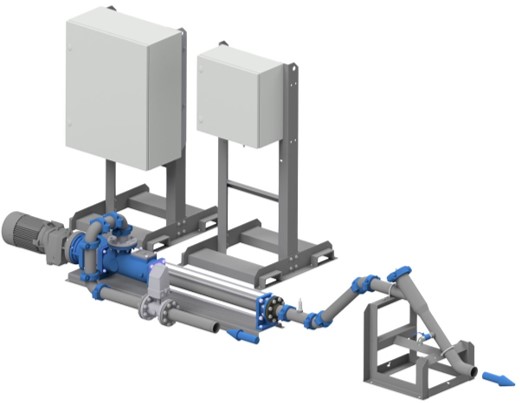

. Simem@tic 3.0

The automation system specifically designed for dry plants that offers a simple and quick interface to control the production process.

Simem@tic 3.0 dry is available for model Four and Linear only.

DESIGN

. Self unloading Self Erecting

Optional: Mixer support platform and aggregate modules are designed to allow transport on standard trucks. After arrival on site, an extremely easy SELF UNLOADING is possible by means of legs positioning, that will release the truck.

Next step is the SELF ERECTION of the plant by means of two hydraulic cilinders that will lift up the mixing unit to its working position.