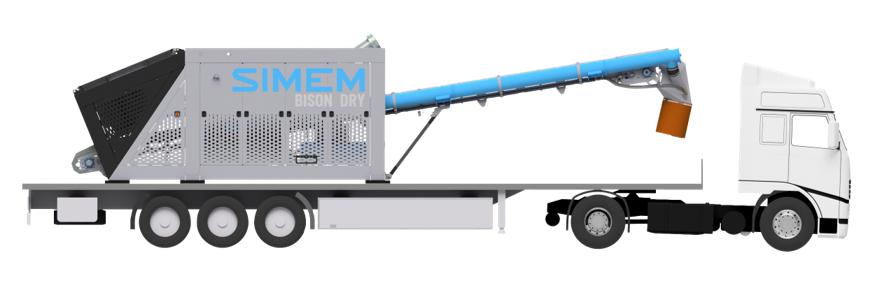

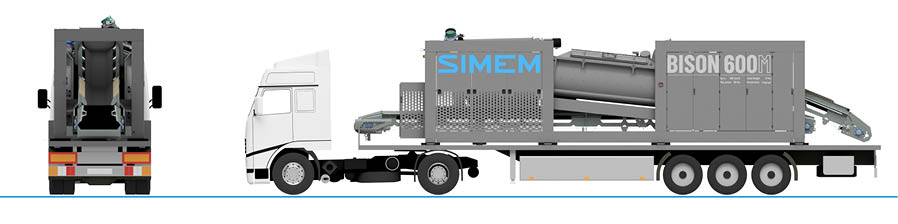

Transportable

with trucks

Production up

to 130 m³/h

Aggregate storage capacity

from 80 to 240 m³

Easy

maintenance

Artik package

available

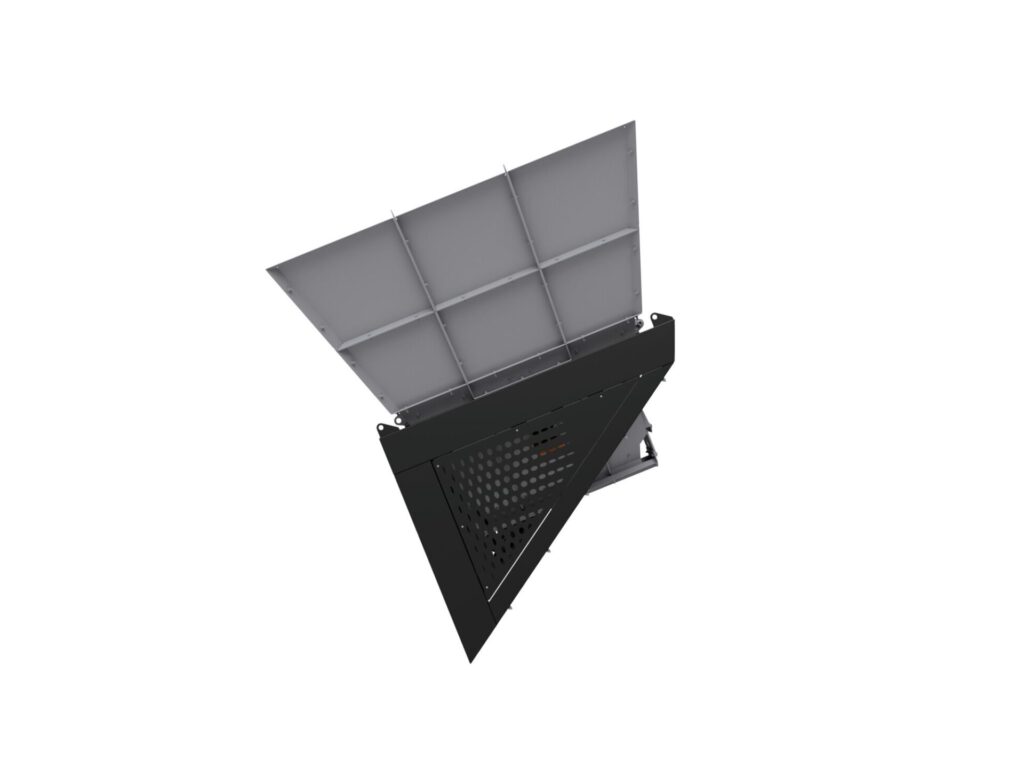

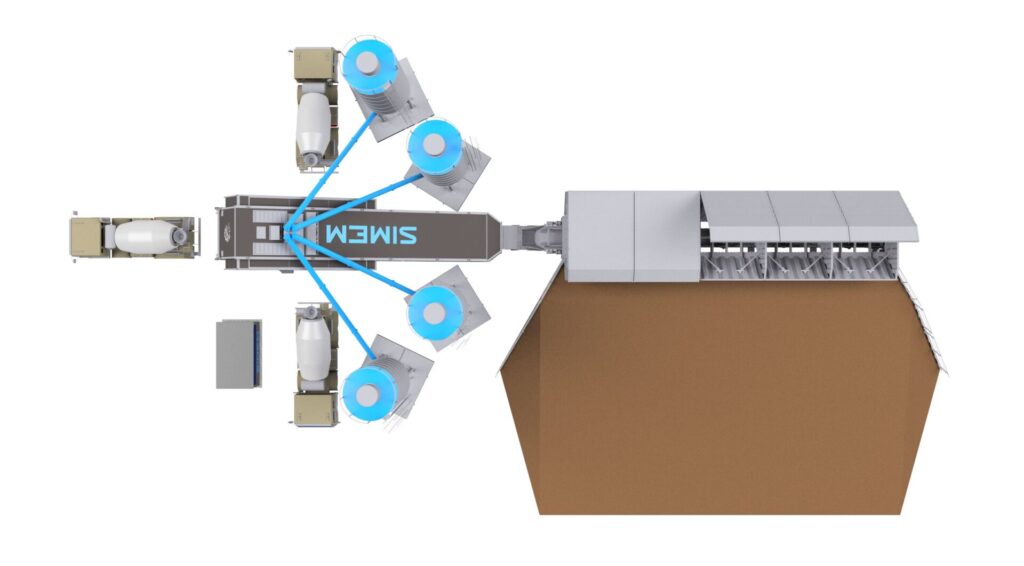

Patented technology - MMX

MMX stands for Mobile Mixing eXcellence, and represents in Roman Numerals the year 2010, which is the year SIMEM has officially launched the state of the art of super mobile batching plants, world wide! Two patents for industrial property referring to the moving mechanism of the mixer and chassis hood-scales were acquired by SIMEM in 2009, clearly establishing the innovation in the MMX. Thanks to these inventions, the concrete batching and mixing plants can ensure an hourly output capacity of 130 m³ of high quality concrete, and have a structure that allows for easy transport with generic vehicles.

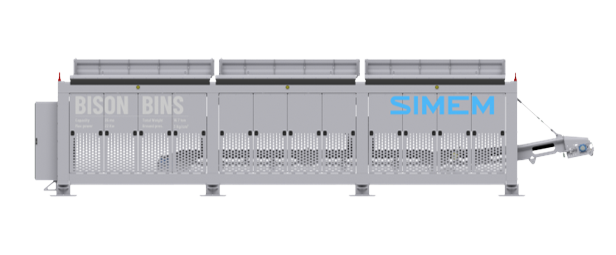

Modular Concept

The aggregate section is expandable by adding additional modules and changing the belt conveyor head: this allows to add the available hoppers and therefore the type of aggregates. Regarding storage capacity of aggregates, the aggregates configuration can easily switch from the basic 80 m3 configuration to 240 m3.

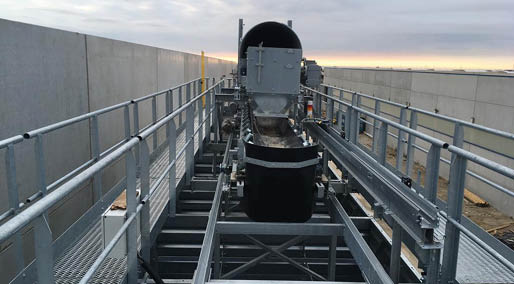

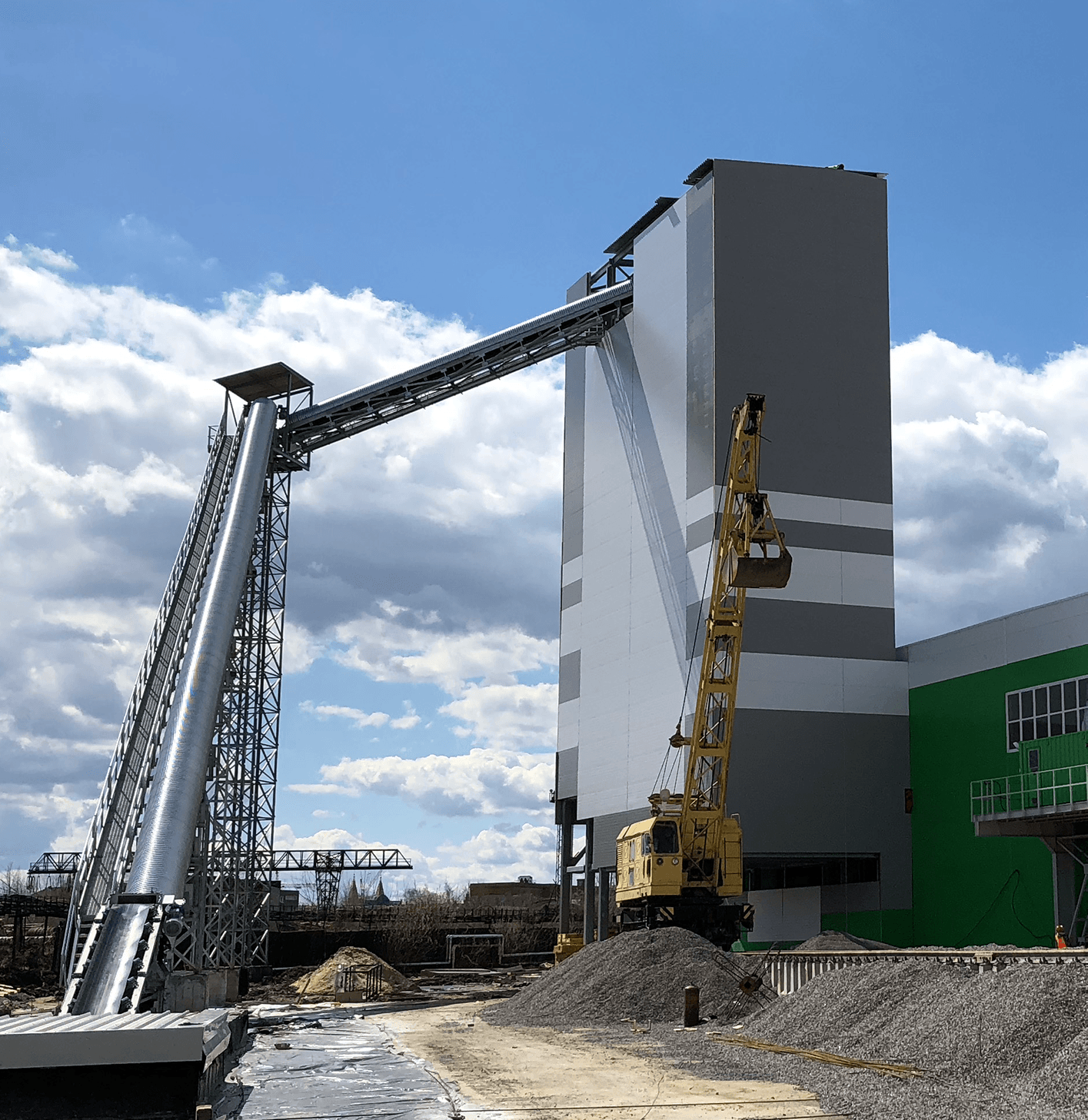

Smart Installation

The support structures of the aggregate and mixer modules are all pre-assembled, pre-wired and automated: thus, it is extremely easy and fast to configure the modules from the transport to the working position.Internal setting (conveyors belt, mixer positioning, scale of cement and water) is fully automated by an automatic hydraulic system.

No civil works are required as the bulkheads below the aggregate

module have a double function to support the aggregate module

due to large areas of support. Moreover, it act as restraints for the

items loading ramp for aggregate feeding.

Easy Transport and cost reduction - Mobile unit

The aggregate module only needs one vehicle to be transported as hopper walls and containing walls for ramp collapse into the aggregate module. Mixing and dosing module are transported as one unit thanks to the patented movement.

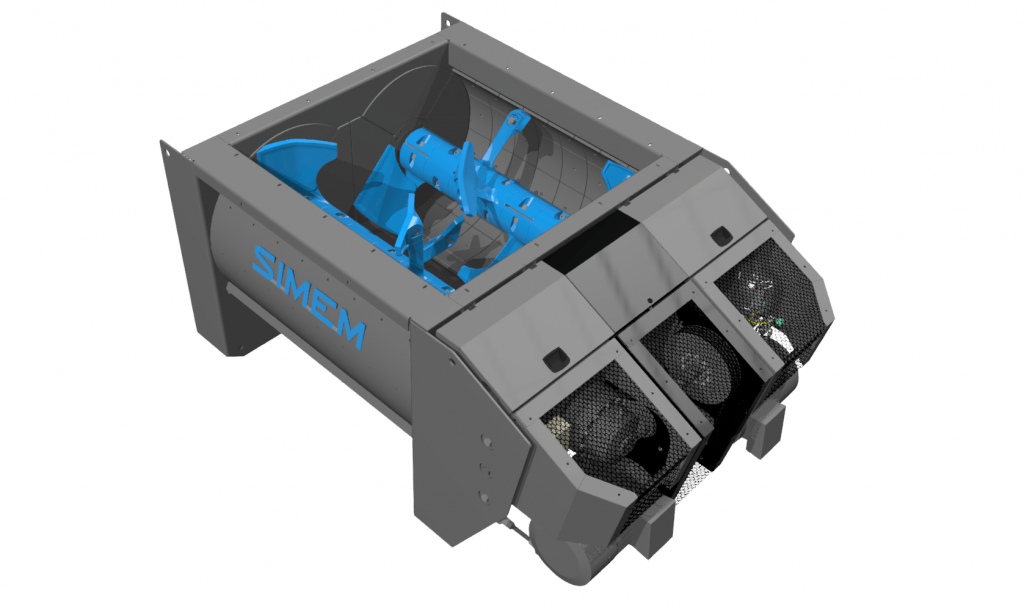

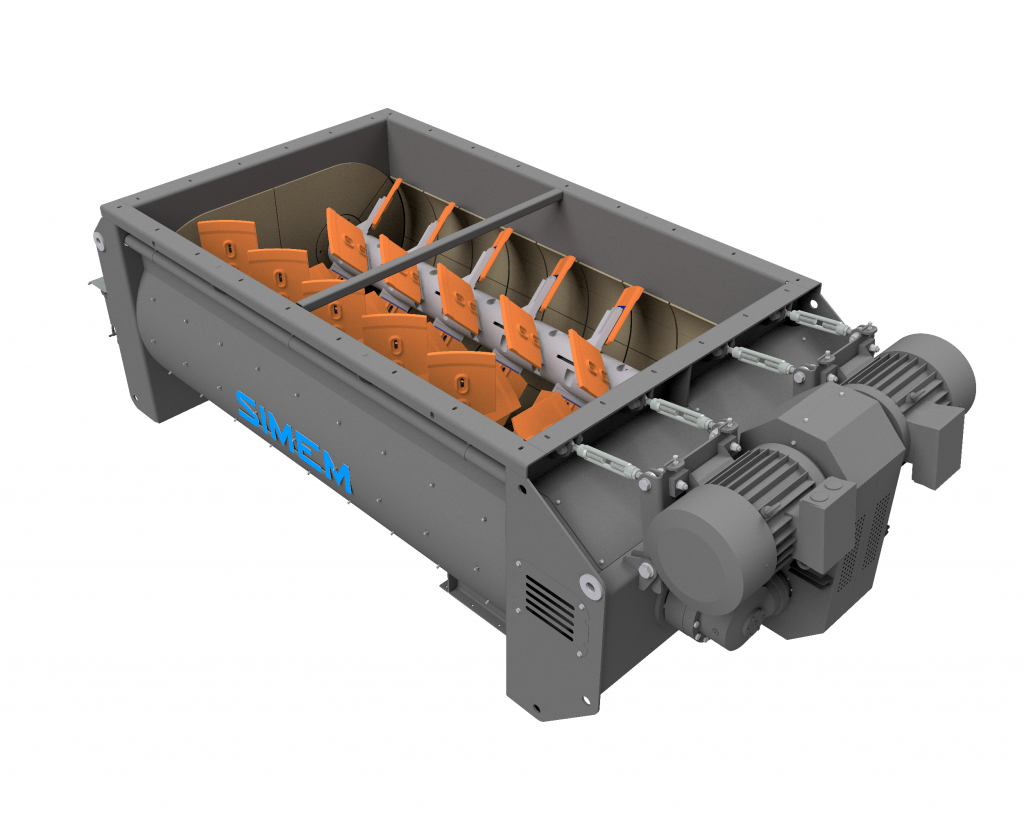

MSO - Twin Shaft Mixer

- High-quality twin shaft mixer featuring construction strength, high productivity, high quality of wear parts with the lowest maintenance cost per cubic meter of concrete produced.

- Hydro-dynamic engineering contributes to mixing paddles and arms reduce wear also providing an optimized mixing result.

- Heavy-duty and long-lived mixer suitable for WET and SCC concrete, RCC concrete, MASS concrete and applications for treatment of industrial solid waste

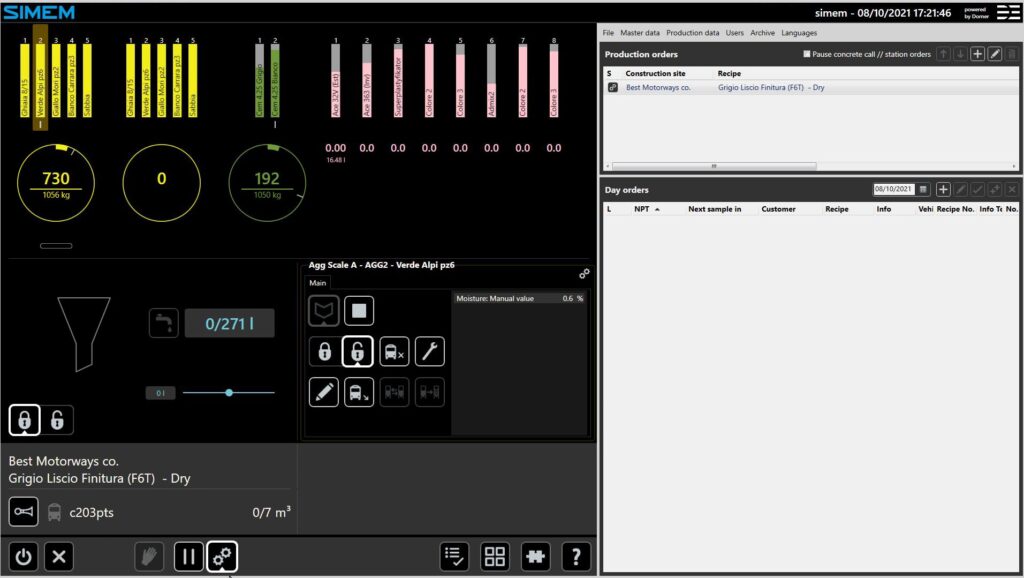

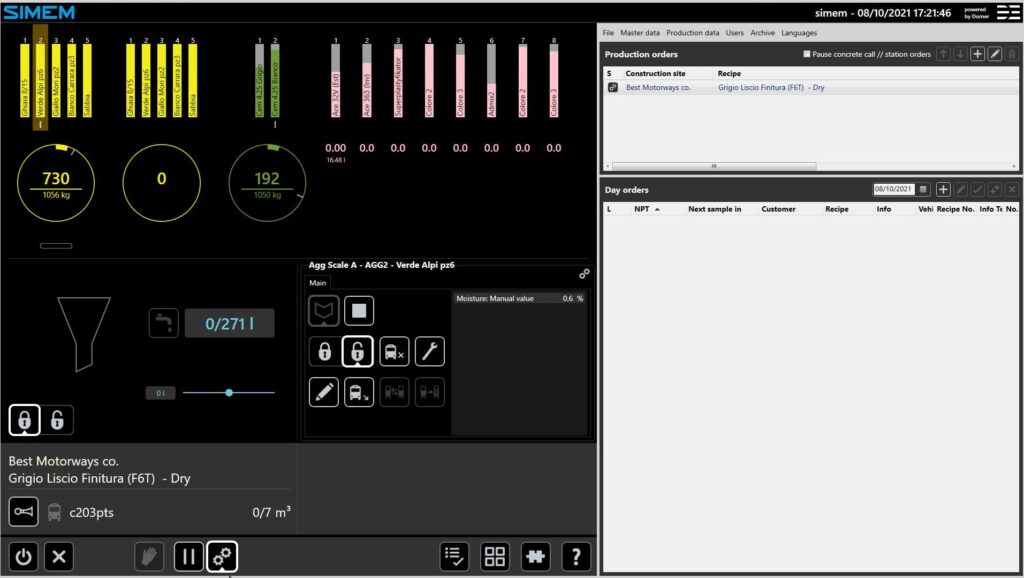

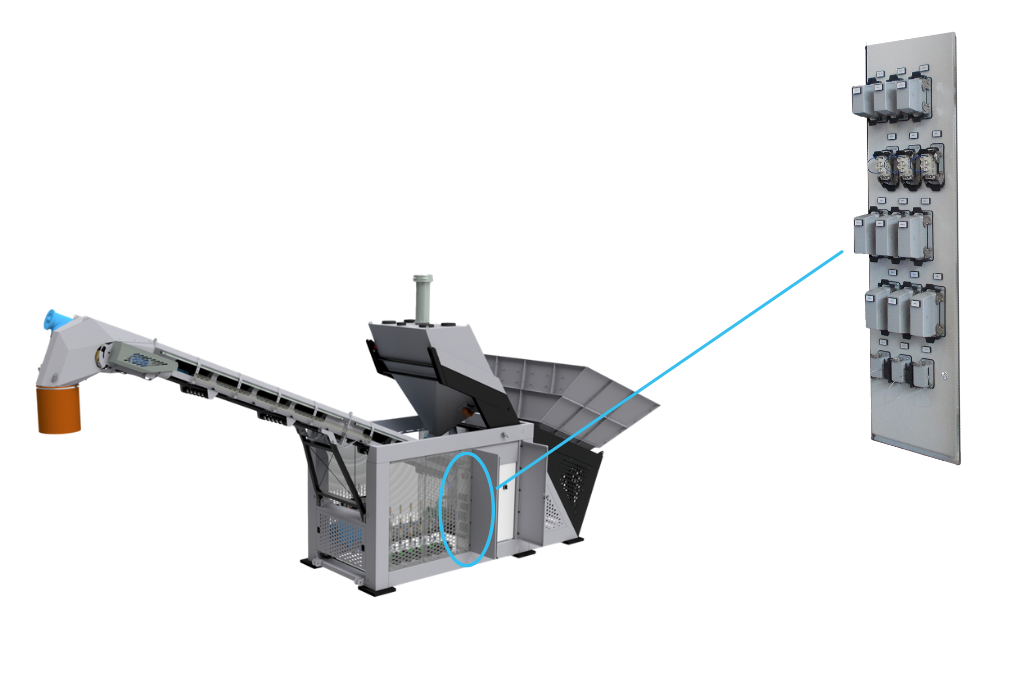

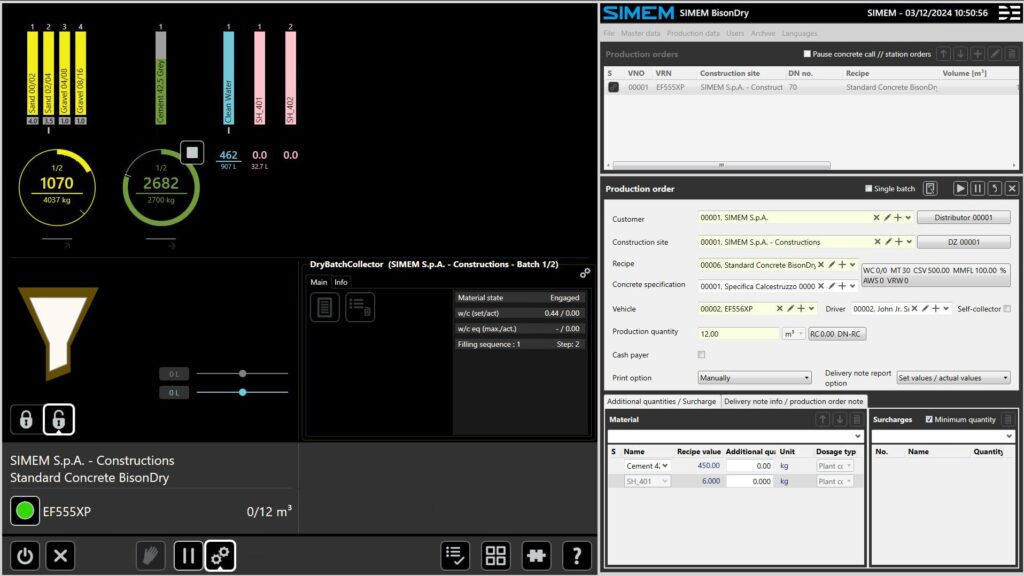

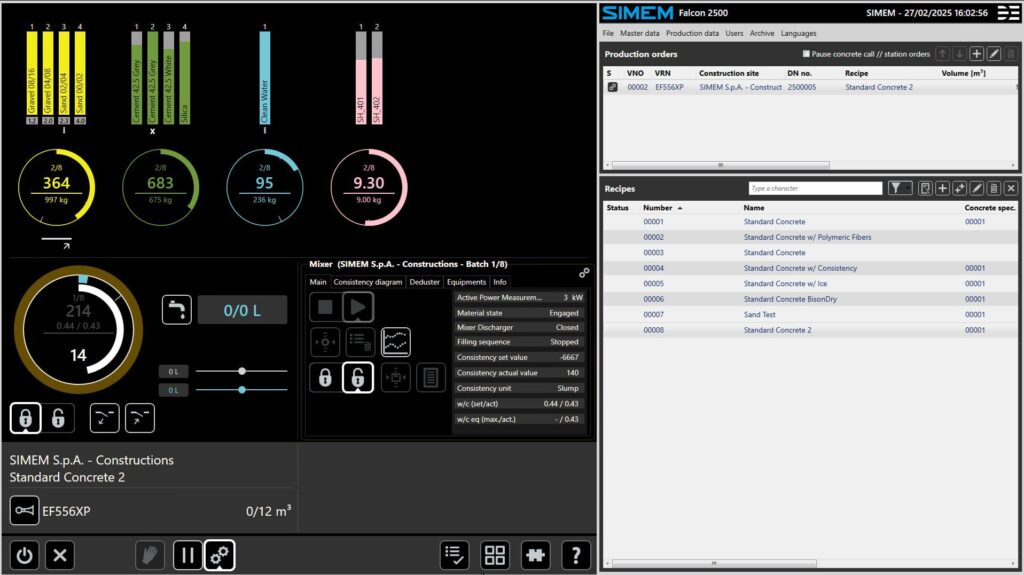

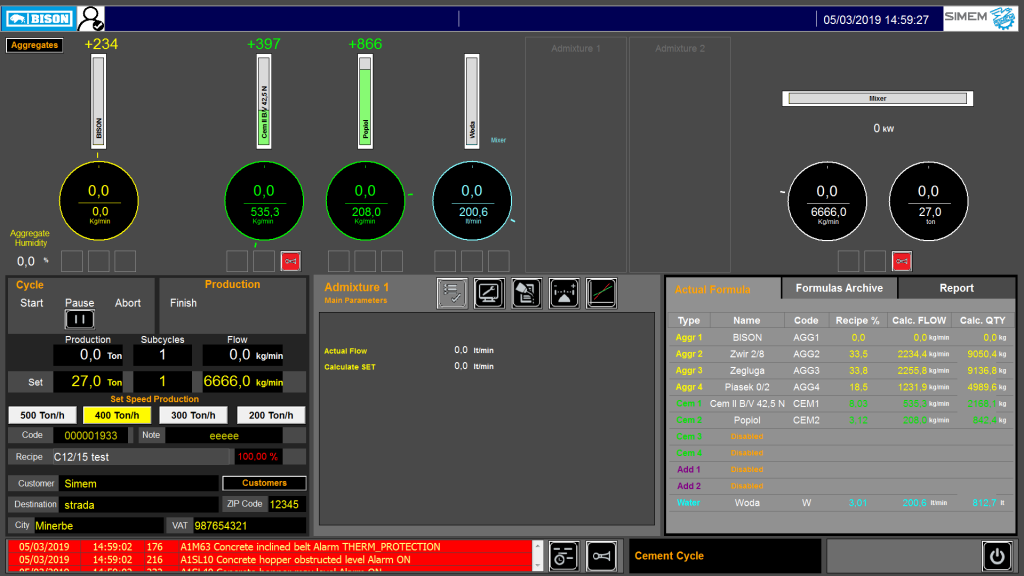

Automation Simem@tic 3.0

SIMEM@TIC is the automation control system with a friendly interface which displays all essential plant operation information. A full process sequence view (loading, weighing, recipe, discharge, washing, production listing, pending orders) with self-adjusting software for a predictable and repeatable outcome. All production data is recorded and stored in SQL database format providing detailed record of concrete production.