DESIGN

. Expertise Solutions

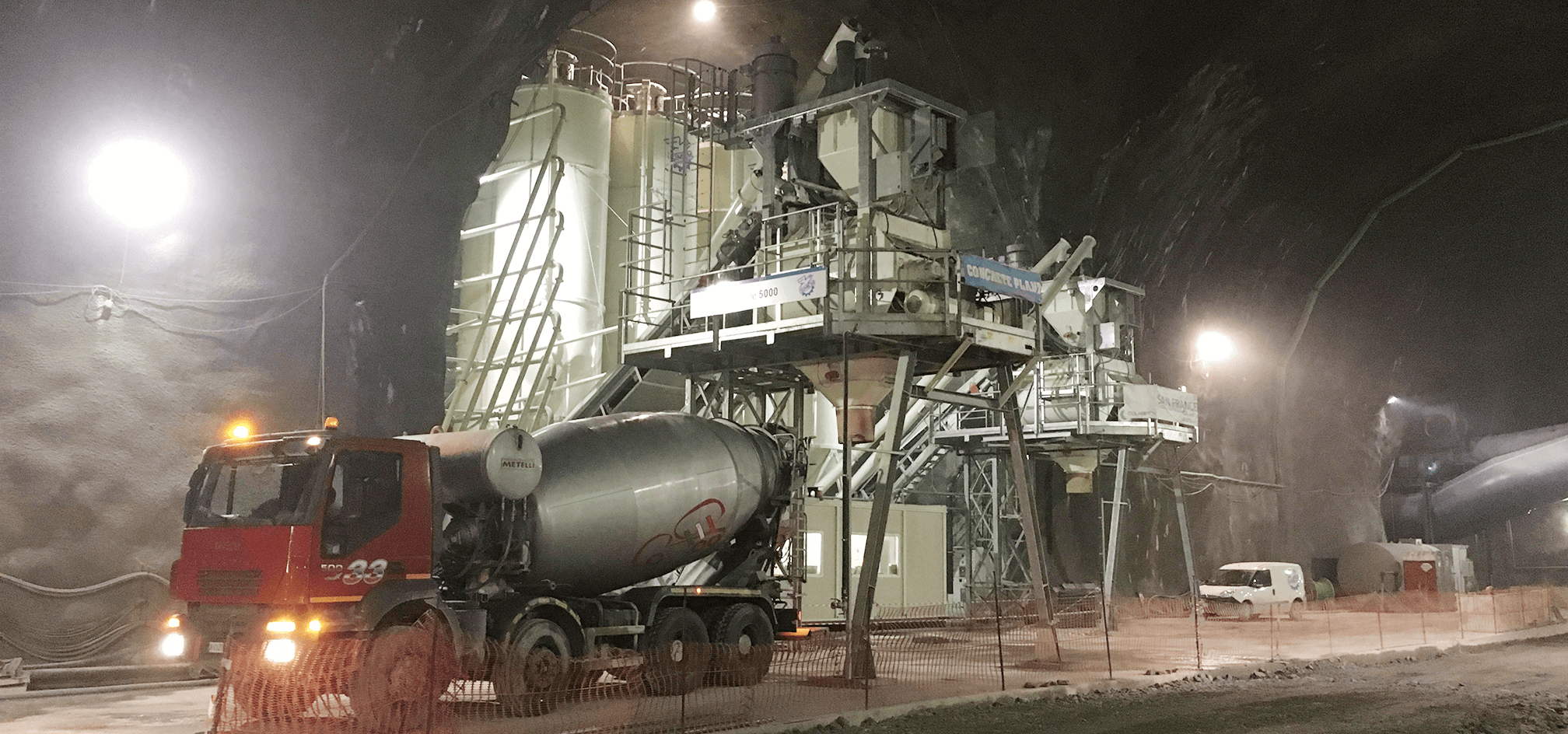

Pastefill allows mining operations to proceed safely and efficiently with higher strength backfill properties than hydraulic fill, while minimizing the need for water handling.

DESIGN

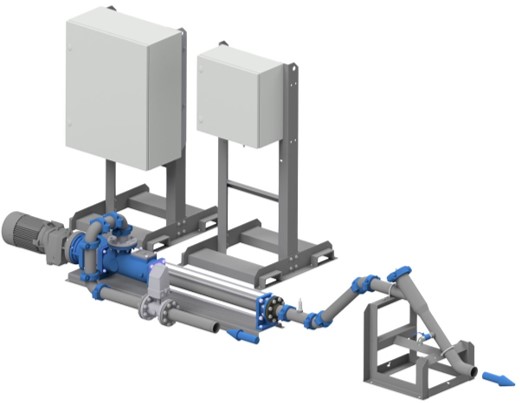

. VORTIMIX Mixer

State-of-the-art high-shear colloidal mixers provide homogeneous, stable mixes that resist bleed and give higher compressive strengths.

Discover more here

DESIGN

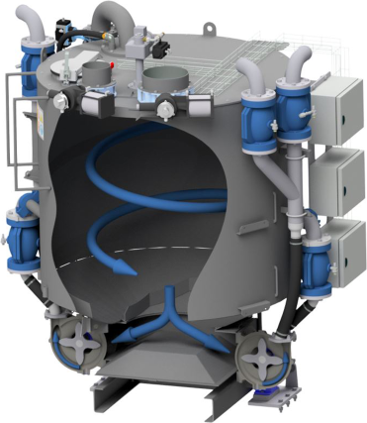

. MDC Mixer

Wear-resistant liners and Ni-Hard cast iron paddles are hydro-dynamically designed provide optimized mixing results.

Discover more here

DESIGN

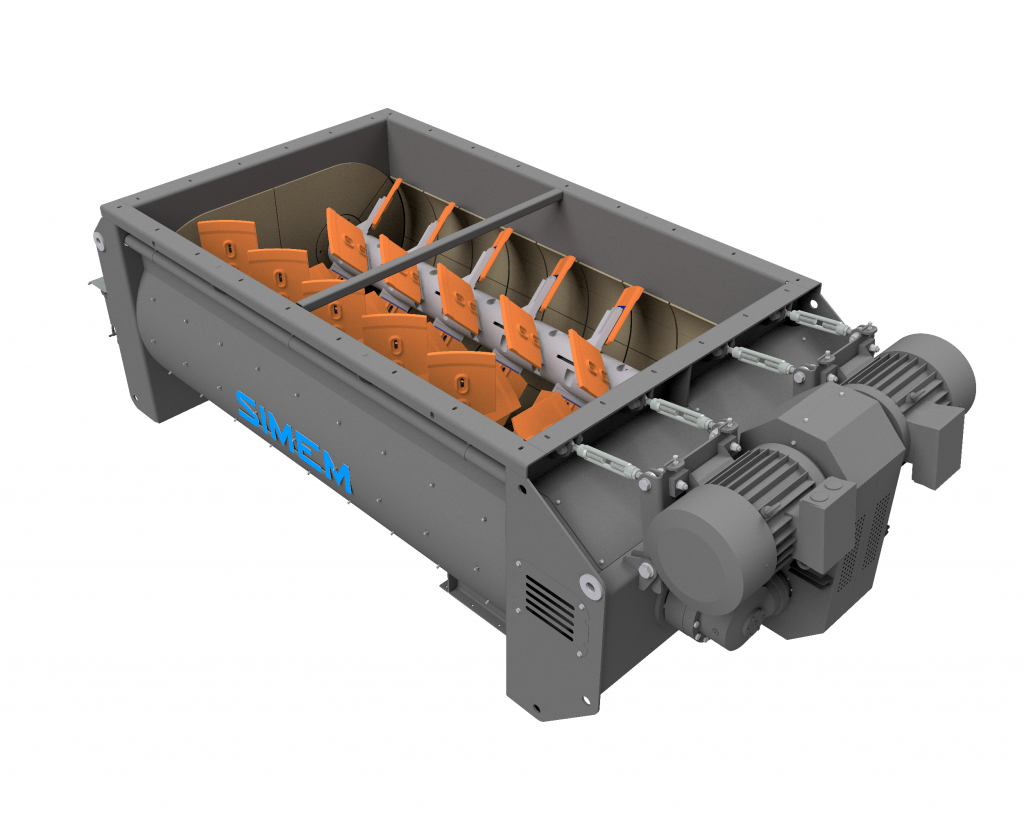

. MSO Mixer

High-quality MSO twin shaft mixers provide the lowest maintenance cost per cubic yard of concrete produced.

Discover more here