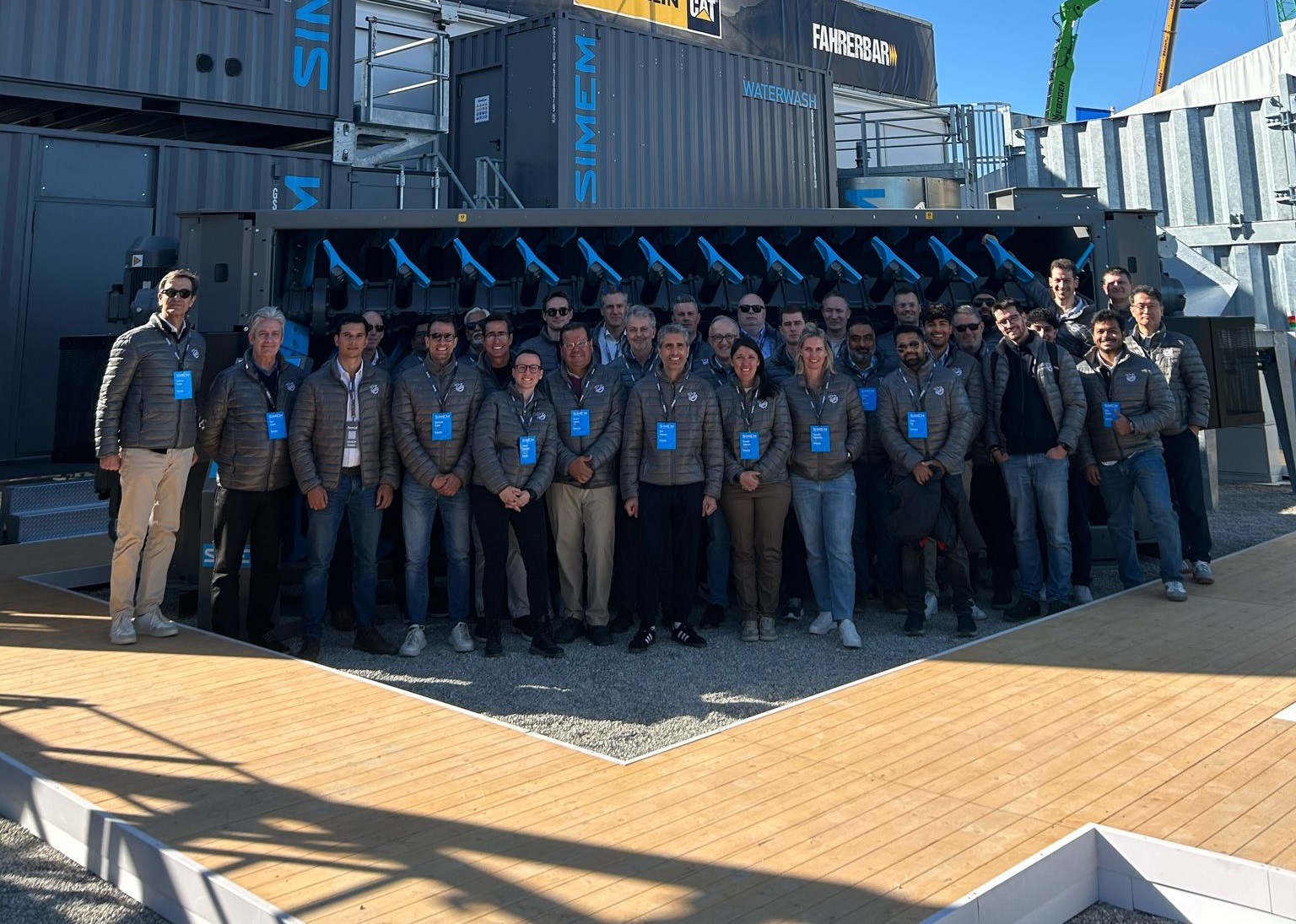

SIMEM S.p.A Strengthens Australian Presence with PrimeBatch Pty Ltd – The Official Exclusive Distributor for Australia and Papua New Guinea

At SIMEM S.p.A, we are proud to reaffirm our long-term commitment to the Australian market through our trusted partner and exclusive distributor, PrimeBatch Pty Ltd. Headquartered in Brisbane, PrimeBatch has been appointed the distributor of the SIMEM concrete batching product range across Australia and Papua New Guinea, bringing our world-renowned Italian engineering directly to customers with genuine factory support and local responsiveness.

Snowy 2.0 represents the qualitative capacity of Simem plants and the PrimeBatch service

A flagship example of this successful partnership is already in full operation at one of Australia’s most significant infrastructure projects: Snowy 2.0. PrimeBatch is proudly supporting the five large-scale SIMEM concrete batching plants currently producing the high-quality concrete required for this nation-building pumped-hydro scheme in the Snowy Mountains. From plant support and ongoing technical assistance to rapid spare-parts supply and specialised operator training, PrimeBatch ensures that these critical SIMEM installations continue to deliver the reliability, precision and output that the project demands, even under the most challenging alpine conditions.

Beyond Snowy 2.0, PrimeBatch is actively expanding its nationwide footprint with dedicated service teams, local spare-parts inventory and demonstration facilities, making the entire SIMEM portfolio available for ready-mix producers, precast factories, mining operations and major civil contractors throughout Australia and Papua New Guinea.

Contact our team for Australia and Papua New Guinea

With PrimeBatch as our exclusive partner on the ground, Australian customers can now specify SIMEM with absolute confidence, knowing they receive authentic Italian technology backed by world-class local service. We invite the industry to discover how this powerful alliance is already powering Australia’s future by reaching out to PrimeBatch using the details below.

For more information on SIMEM solutions now available through PrimeBatch Pty Ltd, please visit www.primebatch.com.au, or visit their LinkedIn page . The PrimeBatch and SIMEM teams stand ready to support your next project, wherever it may be.